|

Environmental Project no. 942, 2004 Substance Flow Analysis of ResorcinolContents

3 Turnover of resorcinol in Denmark 4 Exposure of humans and the environment

5 Environmental and health hazards of resorcinol

PrefaceIn the past years there has been an increasing focus on chemical substances with a potential for endocrine disruption. Resorcinol has been listed as a category 1 substance in the EU priority list of substances for further evaluation of their role in endocrine disruption, mainly because epidemiological investigations has shown that resorcinol has an effect on the thyroid gland. As a follow-up on the report on endocrine disrupters from September 2002 prepared by the Parliament's Environmental and Regional Planning Committee, the Danish Environmental Protection Agency has initiated an investigation of applications of and exposure to resorcinol in Denmark in order to evaluate whether there is a need for regulatory measures regarding its use. The report presents the results of this investigation that has been performed by dk-TEKNIK ENERGY & ENVIRONMENT in close collaboration with the Confederation of Danish Industries. In the project, all available statistical sources have been reviewed and relevant Danish companies have been surveyed by questionnaires and telephone interviews. For dk-TEKNIK ENERGY & ENVIRONMENT, Anders Schmidt and Jan Poulsen have been responsible for compilation of information and preparation of the report. The Confederation of Danish Industries has been responsible for the industrial surveys, with the help of relevant branch organisations (The Danish Plastics Federation, Association of Danish Processindustries, Danish Paintmakers Association, The Association of Danish Cosmetics, Toiletries, Soap and Detergent Industries, The Danish Association of the Pharmaceutical Industry and The Danish Chamber of Commerce (chemical branch). For The Danish Environmental Protection Agency, Frank Jensen has been responsible for the project and has also provided the contacts to the Danish Product Register. The project was performed in the autumn of 2003. Sammenfatning og konklusionerRapporten præsenterer en massestrømsanalyse for resorcinol i Danmark. Analysen er blevet iværksat af Miljøstyrelsen som opfølgning på beretningen om hormonforstyrrende stoffer, som Folketingets Miljø- og planlægningsudvalg afgav i september 2002. Resorcinol er på EU's liste over 66 stoffer med dokumentation for hormonforstyrrende effekter (kategori 1 – høj prioritet), der er prioriteret til yderligere undersøgelser for deres hormonforstyrrende egenskaber (BKH, 2000). Af beretningen fremgår, at resorcinol ikke er under risikovurdering i EU og derfor igangsættes en kortlægning af anvendelsesmønstre og eksponeringsforhold med henblik på at vurdere, om der er behov for at gribe ind overfor stoffets anvendelse. Principperne i massestrømsanalysen svarer i al væsentlighed til de anbefalinger, der er givet i Miljøstyrelsens paradigme for massestrømsanalyser. Der er en begrænset mængde af statistisk information om import, produktion og eksport af resorcinol, og denne er derfor suppleret med henvendelse til alle relevante danske industrier for at forbedre mængde og detaljeringsgrad af informationen. For at etablere et estimat for eksponering af miljøet er regneregler og default-værdier fra EU's Technical Guidance Document for risikovurderinger anvendt i beregninger af emissioner til luft, vand og jord fra de processer, der finder sted i Danmark. Affaldstrømme er bestemt på baggrund af interviews med teknikere i relevante industrier. Informationen om omsætningen af resorcinol i Danmark er opsummeret i Tabel 0.1. Minimum-mængderne i tabellen er de laveste værdier, der er oplyst ved kontakt til danske industrier. Maksimum-værdierne er fremkommet ved at kombinere informationerne fra statistiske kilder med de højeste værdier oplyst via kontakt til danske industrier på det bedst mulige detaljeringsniveau.

Tabel 0.1. Minimum og maksimum mængder (i kg.) af resorcinol omsat i Danmark per år. Det bemærkes, at maksimumsmængden er omkring 5% mindre end det estimat, der kan etableres på baggrund af den statistiske information. Denne forskel tilskrives primært de forskellige detaljeringsniveauer i de enkelte kilder. Forskellen mellem minimum- og maksimumværdier for import af trælim er primært relateret til, at mængderne er beregnet på baggrund af intervaller, mens forskellen i værdierne for resorcinol til produktion af gummiprodukter er et udtryk for forskellen mellem oplysninger fra stikprøveundersøgelsen og de statistiske oplysninger. Det givne interval vurderes imidlertid til at være repræsentativt for omsætningen af resorcinol i Danmark. I Tabel 0.2 kombineres det lave og høje estimat for omsætningen af resorcinol med regneregler i EU's Technical Guidance Document til et estimat for udledninger til luft, vand og jord. Denne fremgangsmåde antages at give et realistisk estimat, om end det vurderes at være forholdsvis konservativt.

Tabel 0.2. Minimum og maksimum estimater for udledninger af resorcinol i Danmark. Alle tal er angivet i kilo. Der er meget sparsom information om dannelse af resorcinol-holdigt affald i Danmark. Tabel 0.3 opsummerer den information, der er blevet etableret på baggrund af interviews med teknikere i relevante industrier.

Tabel 0.3. Mængder (i kilo) af resorcinolholdigt affald i Danmark. 1 Kemikalieaffald til Kommunekemi De følgende tal giver de vigtigste konklusioner om omsætning af resorcinol i Danmark ifølge den gennemførte massestrømsanalyse:

Det største potentiale for eksponering af mennesker vurderes at være i forbindelse med hårfarvning. Med anvendelse af EU's regneregler for test af indholdsstoffer i kosmetikprodukter kan optagelsen gennem huden beregnes til 60 mg ialt eller 1 mg/kg legemsvægt per hårfarvning med de produkter på det danske marked, der har det største indhold af resorcinol (1.13%). Det skal dog bemærkes, at EU's kosmetikdirektiv tillader et indhold på op til 5% og at den maksimale eksponering derfor kan være en faktor fem højere. Det er også ved hårfarvning, at det største potentiale for udledninger til spildevand findes. Udover de ovennævnte tal for omsætning af resorcinol i Danmark skal det nævnes at der også er en omsætning af resorcinol i dæk og træprodukter, der im- og eksporteres til/fra Danmark. I sådanne produkter er resorcinol stærkt bundet i en matrix og vurderes derfor ikke at være tilgængeligt for miljøet i nævneværdigt omfang. Det er derfor ikke inkluderet i den primære massestrømsbalance for Danmark. Det er svært at pege på en trend i forbruget af resorcinol på baggrund af undersøgelsen. De statistiske kilder viser et nogenlunde konstant forbrug i de sidste par år, men kontakterne til relevante danske industrier tyder mest på et let faldende forbrug. I praksis vil det først og fremmest være udviklingen indenfor træindustrien i form af produktion af limtræ til bærende konstruktioner og høj-kvalitets krydsfiner, der er afgørende for mængden af resorcinol, der anvendes i Danmark. Andre anvendelser, der også har stor indflydelse, er i gummiprodukter som transportbånd og drivremme, til kemisk syntese og i hårfarver. Figur 0-1. Massebalance for resorcinol i Danmark. De angivne mængder refererer til minimum og maksimum estimater i kilo. Massebalancen for resorcinol i Danmark viser, at anvendelsen først og fremmest finder sted i produkter, hvor resorcinolen bliver bundet i en matrix, hvorfra der ikke kan forventes yderligere udslip til miljøet, primært i træ- og gummiprodukter. En signifikant mængde omdannes ved kemisk syntese, men synteseproduktet er ikke kendt, og endelig vil anvendelsen i hårprodukter og lægemidler medføre en eksponering af mennesker og/eller miljø, inden det nedbrydes. Det er vanskeligt at pege på substitutionsmuligheder for resorcinol. Den amerikanske interesseorganisation for sojadyrkere, United Soybean Board, har konkluderet, at soya-baserede lime kan indgå som en komponent i lime med resorcinol, og dermed erstatte noget af denne, uden at limegenskaberne forringes. Gummibranchen er som hovedregel meget hemmelighedsfuld omkring processer og materialer, og det er ikke muligt på baggrund af projektets undersøgelser at pege på substitutionsmuligheder. Det samme er tilfældet med hensyn til hårfarver, hvor resorcinol anvendes som coupler i farvesystemet. Heller ikke her har det været muligt i projektet at beskrive den præcise funktion eller pege på substitutionsmuligheder. Summary and conclusionsThe present report presents a substance flow analysis (SFA) for resorcinol in Denmark. The SFA has been initiated by the Danish EPA as a follow-up to the report on endocrine disrupters prepared by the Parliament's Environment and Regional Planning Committee in September 2002. Resorcinol is listed as a category 1 substance (substance of high concern) in the EU priority list of substances for further evaluation of their role in endocrine disruption (BKH, 2000). The report states that resorcinol is not under the on-going risk assessment procedure in the EU and therefore an analysis of use patterns and exposure will be carried out in order to evaluate if there is a need for regulatory measures regarding its use. The approach in the SFA is essentially similar to that recommended in the Danish paradigm for substance flow analysis. Only a limited amount of statistical information is available for import, production and export of resorcinol-containing products, and a survey of relevant Danish industries was performed in order to enhance and detail the statistical information regarding consumption of resorcinol. In order to give an estimate of environmental exposure to resorcinol, the calculation rules and default values in the EU Technical Guidance Document were used to calculate emissions to air, water and soil from the processes taking place in Denmark. Amounts of waste generated were estimated based on interviews with technicians in relevant industries. The information regarding resorcinol is summarised in Table 0.1. The minimum amounts given in the table are best case (lowest values) information from the industrial survey and the maximum amounts are combined statistical and survey information using the best possible level of detail.

Table 0.1. Minimum and maximum amounts (in kilo) of resorcinol imported for processing and use in Denmark. It is noted that the maximum estimate is lower – about 5% - than the estimate based on statistical information. The difference can be ascribed to the different levels of detail of the information sources. The difference in minimum and maximum values for import of wood glue is primarily related to the content being reported in intervals, while the difference for rubber production reflects the differences between information from the industrial survey and the available statistical information. However, the range given in the table are judged to be fair estimates of minimum and maximum amounts for the flow of resorcinol in Denmark. In Table 0.2, the low consumption estimate from the survey is combined with the high (worst case) estimate from the combined statistical and survey information. Together, they are assumed to give a realistic figure for the range of emissions of resorcinol to different compartments of the environment when the EU TGD calculation rules are applied.

Table 0.2. Minimum and maximum estimates (in kilo) of emission of resorcinol in Denmark. There is very little information available on generation of waste containing resorcinol. The information is summarized in Table 0.3 below.

Table 0.3. Generation of waste (in kg) containing resorcinol in Denmark. 1 Chemical waste disposed at Kommunekemi The following figures are the most important conclusions from the substance flow analysis:

The largest potential for human exposure is assumed to be from hair dyeing with resorcinol containing products. Using the EU calculation rules when testing cosmetic ingredients for their safety evaluation, the potential intake through skin contact can be estimated to 60 mg per hair dyeing process, or 1 mg/kg body weight. It is remarked that the EU Cosmetics Directive permits a concentration of resorcinol up to 5% and in this case, the exposure will be a factor five higher. It is also the hair dyeing process that holds the largest potential for emissions via waste water. Additionally to the above figures for turnover of resorcinol in Denmark it is mentioned that there is an import and export of resorcinol that is strongly bound in a matrix in tires and wood products. This resorcinol is assumed not to be available for environmental exposure and is therefore not included in the overall material balance for Denmark. It is difficult to point to a trend in the Danish consumption of resorcinol. The statistical information shows a fairly constant consumption, while the survey of Danish industries indicates a small decrease in consumption. In practice, changes in the turnover of resorcinol in Denmark will primarily be related to the development in the wood industry, using resorcinol for production of laminated wood construction and high-quality plywood. Other important areas are manufacturing of rubber products (conveyor belts and V-belts), chemical synthesis and hair-dye products. It is, however, not possible to establish a general trend for either of the applications. Figure 0-1. Mass balance of resorcinol in Denmark. The stated amounts refer to the minimum and maximum estimates in kilos. The mass balance for resorcinol in Denmark thus shows that the use primarily relates to products in which resorcinol is bound in a matrix where further emissions cannot be expected. A significant amount is transformed by chemical synthesis (to an unknown product or products), while the use in hair dye products and pharmaceuticals causes an exposure of humans and environment before the substance is degraded. It is difficult to point to alternatives to resorcinol that have the same properties and are readily available. In the wood industry, the United Soybean Board (an interest organization for US soybean farmers) claims that soy-based glues can be used as extenders for resorcinol-containing glues in some applications. The soy-based glue can only replace some of the resorcinol, and the main difference is therefore that smaller amounts are used. With respect to rubber products, it is very possible that substitutes for resorcinol are available. However, the rubber industry is traditionally very secretive about its materials and processes, and it is therefore not possible to point to specific solutions. In hair dyeing products, resorcinol is used as a coupler in the colouring system but it has not been possible to determine the exact function more precisely in the current project. Accordingly, it is also not possible to point to possibilities for substitution of resorcinol. 1 Introduction1.1 Purpose of the analysis 1.1 Purpose of the analysisResorcinol has been prioritized as being a chemical compound of high concern because studies have provided evidence that resorcinol may cause endocrine disruption (BKH, 2000). In order to provide an overview of the flows of resorcinol in Denmark and its potential for exposure of the environment and humans, the Danish Environmental Protection Agency has initiated the present substance flow analysis of resorcinol in Denmark. The purpose of the analysis is to investigate the use, consumption and disposal of resorcinol in order to provide an overview of its dissemination and exposure potential. Resorcinol is known to have a potential for human exposure through pharmaceuticals, different types of cosmetics used on the skin, and by inhalation of wood and cigarette smoke. However, the extent of the exposure in Denmark has not previously been investigated. 1.2 Methodology and limitationsThe investigation is made as an overview analysis of the flows of resorcinol in Denmark. The main fields of application and the sources of environmental exposure related to resorcinol are identified. The basic principles of the investigation are similar to those defined in the paradigm for substance flow analysis developed for the Danish EPA (Lassen & Hansen, 2000). However, due to limited statistical information, the main flows of resorcinol have also been estimated by direct contact to Danish industries. The two types of information are combined to give a low and a high estimate for flows of resorcinol in Denmark. The EU Technical Guidance Document for estimation of emissions in relation to risk assessment has been used to establish figures for emissions to air, water and soil from all resorcinol-related activities in Denmark. This is not an element in the paradigm, but was judged to be applicable despite – and because – of the limited amount of information. The report thus provides both a realistic estimate of the range for resorcinol consumption in Denmark, and a fairly conservative estimate of exposure of the environmental compartments air, water, and soil as well as amounts and fate of resorcinol-containing waste. By establishing both types of information, the report is better suited for decision-support, e.g. in relation to the need for a risk assessment or potential regulatory measures. The main limitation of the study is the uncertainty regarding the completeness of the statistical information. Some information may be missing and other figures may be over- or underestimated due to changes in consumption patterns. On the exposure side, the main limitation of the study is the lack of knowledge regarding the state of resorcinol when emitted with waste water, i.e. has the compound reacted with other substances or is it still in its active form? 1.3 What is Resorcinol?Resorcinol is the meta (1,3) isomer of dihydroxybenzene. The molecular structure is illustrated below.

Figure 1-1 The molecular structure of Resorcinol. The hydrogen atom surrounded by the two meta-hydroxyl groups can be substituted much more easily than the other ring hydrogens. Compared to catechol and hydroquinone, resorcinol has the highest reactivity toward formaldehyde (Ullmann's, 2002). Resorcinol is produced with benzene as the main feedstock. In The United States resorcinol is produced using the “classical” route via 1,3-benzenedisulfonic acid. In Japan, resorcinol is produced via 1,3-diisopropylbenzene (Ullmann's, 2002). 1.3.1 SynonymsVarious synonyms and abbreviations of resorcinol are used in the literature. In this report the trivial name resorcinol is used. Some of the synonyms used include 1,3–Benzenediol, 1,3-Dihydroxybenzene, 1,3–Benzoldiol, m-Hydroquinone and Resorcin (HSDB, 2003). 1.3.2 Chemical and physical propertiesResorcinol [Cas. No. 108-46-3], C6H6O2 is a dihydric phenol and exhibits the typical reactivity of a phenol. Its most important reaction is with formaldehyde to form phenolic resins (Ullmann's, 2002). Resorcinol is a white to off-white needle-like crystals, flakes or powder. When exposed to light and air resorcinol crystals acquire a pink tint (NTP, 2003). It has a weak odor and a bittersweet taste. Resorcinol does not occur naturally, but has been found in waste effluents from coal gasification and as a pollutant in filtered ground and surface water at a waste treatment plant (Spectrum Laboratories, 2003). It has been produced industrially for more than 100 years (Ullmann's, 2002). The typical chemical and physical properties of resorcinol are presented below (NTP, 2003).

1.4 International market and trends in consumption1.4.1 Global market and consumptionGlobal production of resorcinol reached 46,000 metric tons in year 2000, representing a total value of $233 million. The United States is the largest producer and consumer of resorcinol. In 2000, the U.S. plant operated near full capacity, while Japanese production exceeded its nameplate capacity (Hajduk, 2001). In addition, there are three small plants in China, two in India and an additional plant in Japan (Spectrum laboratories, 2003). Western Europe's last remaining resorcinol plant was closed in late 1991 because of environmental concerns. Since then, periodic announcements state that a new resorcinol plant will be built in Europe. However, no such plant is currently under construction and all plans appear to be postponed indefinitely. Japanese resorcinol production is primarily for export (80% of production was exported in 2000). Capacity in Japan was last increased in late 1993. Trade among regions is significant: more than one-half of the world production is exported (about 29 thousand metric tons in 2000). From 2000 to 2005, world consumption of resorcinol is expected to grow at a 0.6% average annual rate, with Japan exhibiting no growth, Europe contracting and the developing regions growing at 3-4% (Hajduk, 2001). The primary consumer of resorcinol at the global level (more than 50 %) is the rubber industry. In the production of tires and other reinforced rubber products (conveyor belts, driving belts),

resorcinol-phenol-formaldehyde condensates are used to enhance adhesion between cord and rubber (dip formulations, dry bonding agents). Furthermore, some rubber mixtures contain resorcinol to

improve properties after curing.

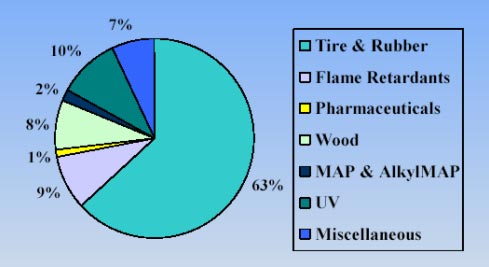

1.4.2 EU market, consumption and trendsThe European Community imported approximately 13,000 tons of resorcinol in year 2001. From 1979 to 1990 the import of resorcinol to Western Europe grew from 2,300 to 3,300 tons. From 1991 and 1995 the import was much higher and fluctuated between 7,000 to 10,700 tons. From 1996 to 1999 the import has grown from 9,000 to 9,600 tons, which is equivalent to about 1.6% annually (RTF, 2002). The distribution of the imported resorcinol for use in different industries can be seen in Figure 1-2 below. As can be seen, the consumption pattern differs somewhat from the overall international consumption, the main uses being in tire and rubber production, but with a lower use in wood production, only 8% compared to the 25% observed internationally.

Figure 1-2. Illustration of the use of resorcinol according to industry in the European Community. Reprinted from (RTF, 2002). (MAP = m-aminophenyl production). 2 Applications in Denmark2.1 Manufacture of wood products According to the Danish Product Register, the most frequent industrial sectors consuming resorcinol are:

In the following sections the main applications in the above industrial sectors are described briefly, together with applications in three additional industries, namely cosmetic, chemical and pharmaceutical industry, all of which consumes some of the resorcinol imported to Denmark. For some of the industries, applications of resorcinol can be identified precisely whereas for others, it has not been possible to verify actual use. 2.1 Manufacture of wood productsHigh quality wood glues and hardeners can be made from resorcinol, phenol, and formaldehyde. These resorcinol-phenol-formaldehyde resins are used for load bearing constructions and laminated wood constructions, including plywood, especially where water resistance must be achieved. 2.2 Manufacture of rubber productsResorcinol is used in the rubber industry as a primer in coating of fabric with latex, e.g. on cords, tires and mechanical rubber goods like conveyer belts and forklarV-belts. It is also used as a glue in manufacturing of rubber products, e.g. when joining the ends of a conveyor belt. 2.3 Manufacture of iron and steel productsResorcinol is believed to be used as a primer for rubber coating of products of iron and steel. It is also possible to use RFL (resorcinol-formaldehyde latex) dip for direct coating with latex on iron and steel. 2.4 Hair dye productsResorcinol is used in many hair dye products because it has a unique functionality as a coupler. Some products contain up to 2% resorcinol, but the majority of products contain less than 1%. The EU Cosmetics Directive (76/768/EEC) permits a content of resorcinol in hair dye products up to 5% and in hair lotion and shampoo up to 0.5%. 2.5 Pharmaceutical productsResorcinol is found in one pharmaceutical product in Denmark, i.e. in eye drops that can be bought without prescription. Some years ago resorcinol was also found in a number of ointments against diseases like psoriasis and acne, but such products are no longer marketed in Denmark. 2.6 Chemical industryResorcinol is used in chemical synthesis in Denmark, but the industrial survey made by the Confederation of Danish Industries did not reveal information of the synthesis products. Resorcinol is also used in Danish production of wood glue, e.g. as a component in a phenol-resorcinol-formaldehyde glue. 3 Turnover of resorcinol in Denmark3.1 Statistical information The turnover of resorcinol in Denmark is estimated by using available statistical information and by surveys of the industries where the major consumption is assumed to take place. 3.1 Statistical information3.1.1 Statistics DenmarkThere is no record of production of resorcinol in Denmark and there has not been registered any sale of goods containing resorcinol in Denmark between 1995 and 2003 (Statistics Denmark, 2003). The following data presents the available import and export statistics for resorcinol (defined as KN code 2907 2100 “Resorcinol and its derivates”) (Statistics Denmark, 2003).

Table 3.1. Import and export of resorcinol to/from Denmark in 1994-2002. Table 3.1 shows there are large variations in the import and export of resorcinol to/from Denmark. The export generally seems to be significantly smaller than the import and the last years there have been little or no export of resorcinol. It should be noted that the data from Statistics Denmark includes derivates of resorcinol, and the import of pure resorcinol may accordingly be much less than the figures listed in the table. There exists between 10 to 20 derivates of resorcinol that may all be included in the import and export figures. Some of the most important derivates are listed below.

The distribution between resorcinol and resorcinol derivates in the import/export figures from Statistics Denmark are unknown and the exact import/export of resorcinol can thus not be determined. A range for the import of resorcinol in year 2002 can in principle only be estimated to be between 0 kg and 10098 kg. 3.1.2 The Danish Product RegisterTo obtain a cross reference on the import and export figures from Statistics Denmark, the amount of products containing resorcinol has been investigated based on data form the Danish Product Register (PR). It is the notifying companies alone that are responsible for updating in PR. The companies are obliged to send in any relevant information about changes regarding their notified products. Table 3.2 below summarises the compiled information.

Table 3.2. Number of product types and their content of resorcinol. The most frequent industrial sectors consuming resorcinol are described briefly in Chapter 2. It is emphasized that the PR contains data for active as well as non-active products on the Danish market. If a product is not active anymore – or the amounts being imported or produced changes, the notifying company is responsible for giving this information to the PR. However, experience shows that this is not always the case and in practice, the amounts may be both larger and smaller. Another uncertainty in the information from the PR is that there must be more than three products within a given category in order to be included in the information that the PR is allowed to reveal to the public. In theory, there can thus be a large amount of resorcinol in one or two products with a content between 20 and 50%. 3.1.3 The SPIN DatabaseSPIN – Substances in Preparations In the Nordic countries – is a database that contains “non-confidential” information on substances from each of the Nordic product registers. The intention behind the database SPIN is to make available to the public as much data as possible from the registers. Secrecy rules as in the Product Register can then be overcome by aggregation of the data from each register. Thereby, the number of products within a certain use or industry category is increased. The information included is for example the number of products containing the substance, the annual tonnage, industrial categories and use categories, the annual tonnage within these categories and the presence or absence of the substance in consumer products. Information in the SPIN database shows that in 2000, a total amount of 23.6 tons of resorcinol was used in 30 preparations. In 2001, the total use was 23.5 tons in 31 products. The SPIN database also shows that in Denmark resorcinol is used in the manufacture of rubber, plastic, machinery and equipment. In the other Nordic countries resorcinol is also used in the manufacture of products of wood and cork, luggage, handbags, saddlery, harness and footwear, chemicals and chemical products. The typical functions of resorcinol in these products are as adhesives/bindings agents, hardeners, catalysts/process regulators, pharmaceuticals, dyestuff/pigments and intermediate (SPIN, 2003). The SPIN database also provides a quantitative distribution of the amounts of resorcinol on different use categories and EU's Nomenclature of economic activities (NACE). However, only a limited number of products are included in this overview. Table 3.3 below summarises the compilation of information regarding Denmark from the SPIN database for the years 2000 and 2001.

Table 3.3. Number of products and amounts of resorcinol distributed on use categories (UC62 and national) and NACE-codes The SPIN database only shows non-classified information. This means that each category must contain at least four products from at least three different companies in order to be included. If this criteria is not fulfilled the data will not be available. This explains why the presented data from the SPIN database is only a subset of the data from the Danish Product Register. More products are shown within the use categories (UC62) compared to the use categories (national) and the NACE categories. The reason is that the categories within (UC62) are broader defined than the other categories. Products may be registered in more than one category. This means that the 5.9 tons of hardeners registered in year 2000 may also be included in the 19.8 tons of adhesives registered in year 2000. Hence, it is not possible to obtain the total consumption be adding the tonnage from each category. 3.1.4 Discussion of statistical information sourcesThe information from the Danish Product Register can be combined with data from the SPIN database. According to SPIN, there were in 2001 registered 31 different products being imported and used for industrial purposes in Denmark, in total representing 23.5 tonnes of resorcinol. In 2000 there were 30 different products, in total representing 23.6 tonnes. These figures are very similar to the information obtained from the Danish Product Register, giving a total of 23 tons of resorcinol. However, both the Product Register and the SPIN database gives figures for resorcinol import that are significantly higher – about a factor 2 - than the amounts reported by Statistics Denmark. This may be due to the differences in classification of products, e.g. it is not known whether the KN-code used for resorcinol and its derivates include resorcinol in formulations like wood glue. It is concluded from the statistical information that the import and use of resorcinol for industrial purposes amounts to about 23 tons per year. As is shown in the following survey, there may however be an additional consumption that for one reason or another has not been included in the statistical information. The survey also indicates that the some of the amounts reported to the Product Register are not relevant in 2003, i.e. there may be an overregistration in the Product Register when compared to the use reported by industry. 3.2 Survey informationDue to the uncertainties associated with the statistical information, a survey among different industries was performed. The main purpose of the survey was to cross-check or verify the statistical information and if possible obtain more detailed information about the applications of resorcinol in Denmark. With this information better estimates of the potential for human exposure and dissemination in the environment can be established. The survey covered the following industries.

3.2.1 Glue industryResorcinol is a component in different wood glues and hardeners used for load bearing constructions and laminated wood constructions. The Danish Adhesives and Sealants Association contacted all relevant members for information about production and import of glues and hardeners containing resorcinol. A total of 11 companies were contacted and 10 responded to the survey. No production of resorcinol-containing glue was reported by the respondents from the Danish Adhesives and Sealants Association. It is, however, remarked here that 751 kg of resorcinol was imported for glue and adhesive manufacturing in the paintmaking industry and this figure is included in the overview for the glue industry. The total import and production of resorcinol in wood glue is estimated to be between 3.4 and 11.6 tons, see Table 3.4 for details.

Table 3.4. Survey of imports of resorcinol and resorcinol-containing glues for wood products. 3.2.1.1 Fate of resorcinol in wood glue When used as a glue in wood production, resorcinol will be strongly bound in a matrix, and the emissions of resorcinol from the product are assumed to be insignificant. The ultimate fate of wooden products in Denmark is assumed to be incineration with energy recovery. The content of resorcinol does in this respect not change the classification of wood products as being suitable for incineration (Kvist et al., 2000). 3.2.2 Adhesives/bindings agents in the rubber industryResorcinol is used in the rubber industry as a bonding agent or primer to obtain good adhesion and facilitate coating of fabric with latex, e.g. on cords, tires and mechanical rubber goods like conveyer belts and V-belts. Worldwide, typical processes involve the use of RFL-dip (a solution of resorcinol (40%), formaldehyde and latex. In the cord treatment process, a nylon, polyester or aramid cord is unwound from spools and directed into a solvent-based isocyanate primer, followed by flash-off in a hot air oven. The applied primer prepares the cord for the next step, a water-based resorcinol-formaldehyde latex (RFL) primer dip, that creates bonding sites on the cord. Subsequently, the RFL dip is dried by passing the cord through heated oven zones. The last coating operation involves dipping the cord in a solvent-based rubber adhesive tank and finally, the solvent in the adhesive is removed via an evaporation tunnel and the coated cord is spooled (USEPA, 1998). A typical RFL-dip (Bayer Vulkadur T) consists of pre-condensed resorcinol-formaldehyde resin, 40% aqueous solution. Wall components and other segments of hoses, belts and tires are fabricated from fabric coated by using dip and dough spreading techniques. The types of fabrics used in these processes include cotton, cotton/polyester blends, nylon, polyester/nylon, and aramid. RFL-dip is also used for coating of metal with rubber. No information regarding the processes used for such applications has been found in the project. A survey of 14 Danish companies producing a wide range of rubber products revealed that only one company uses resorcinol-containing adhesives in the manufacturing of conveyer belts and V-belts. In the process, small pieces of non-vulcanised rubber are dissolved in the resorcinol solution. The non-vulcanised rubber/resorcinol mixture is used as an adhesive to fasten pieces of for example conveyer belts before they are vulcanised. The adhesive is applied manually with a brush in small amounts. It is estimated that 0.1 gram of resorcinol compound is used per kilo final product. The annual amount of resorcinol-containing adhesive being imported amount to 1300 kg, of which 20% - or 260 kg – is resorcinol. 3.2.2.1 Fate of resorcinol in rubber adhesives The ultimate fate of conveyor belts and V-belts (e.g. for automobiles) is either recycling, incineration with energy recovery or land filling. Recycling is not very likely, because conveyor belts are based on textiles. Incineration with energy recovery is possible, but requires that the belts are cut in sizes that are suitable for incineration. Land filling is also likely, e.g. following a shredding process where the whole conveyor belt is treated in a hammer mill, separating primarily metals from other materials. The metals can be recycled, whereas rubber, textile and plastics fractions are deposited in a landfill. Rubber is not assumed to degrade significantly in a modern landfill and accordingly, the resorcinol will be bonded in the rubber matrix. When resorcinol is incinerated, it will mainly be broken down to CO2, CO, CH4, and NMVOC (Frydendal, 2003). 3.2.3 Hair dye productsResorcinol is used as dyestuff in hair dye products. The Cosmetics Directive allows the use of resorcinol in concentrations up to 5%. According to The Association of Danish Cosmetics, Toiletries, Soap and Detergent Industries (SPT), the majority (98%) of the hair dye products contain less than 1% resorcinol, while the remaining contains 1-2% resorcinol. In a Danish investigation of hair dye products, resorcinol was found in 15 out of 18 products in concentrations from 0.002% to 1.13% (Rastogi, Worsøe & Jensen, 2003). The magnitude of the consumption of resorcinol in Denmark was estimated by SPT using linear interpolation based on the consumption of resorcinol in the EU and the distribution in population: Consumption of resorcinol in hair dye products in the EU: 90 tons (COLIPA, 2003). Based on the above information, consumption of resorcinol in hair dye products in Denmark can be calculated to 1.28 tons Similarly, the magnitude in the consumption in Denmark was estimated by linear interpolation based on distribution of turnover of cosmetics in Denmark and the EU: Consumption of resorcinol in hair dye products in the EU: 90 tons Based on the above figures, the consumption of resorcinol in hair dye products in Denmark can be calculated to 1,35 ton. The two calculations show that the amount of resorcinol in hair dye products sold in Denmark is 1.2-1.4 tons/year. There may be significant differences between the consumption pattern for hair dye products containing resorcinol in EU countries, and the uncertainty in the calculations is assumed to be 25%. This range from 1.0-1.7 tons/year is used in the calculations of the material balance. 3.2.3.1 Fate of resorcinol in hair dye products Resorcinol reacts with the other substances in the hair-dyeing product very quickly. After 15 minutes, the hair is rinsed, emitting surplus colour to the waste water. Likewise, the mixing bowl is rinsed under running water. There is no information available of the concentrations of resorcinol following the reaction phase. In the calculation on emissions to the environment it is assumed that all resorcinol will be emitted, giving a very conservative estimate. 3.2.4 Chemical industryThe Confederation of Danish Industries carried out a survey among selected companies in the chemical industry. Three companies (two glue manufacturers and one importer of chemicals) responded that they have import of resorcinol. The result of the survey is summarised in Table 3.5 below.

Table 3.5. Survey of chemical companies in Denmark The amounts in Table 3.5 are in theory part of the imported resorcinol registered by Statistic Denmark, but it has not been possible to verify this. The figures indicate that out of the total import of 10098 kg only 2751 kg is pure resorcinol while the rest is resorcinol derivates. 3.2.4.1 Fate of resorcinol in the chemical industry The 750 kg used for manufacturing of wood glue ends up as glue in wood products, with the same fate as described in 3.2.1.1. The fate of the single kilo used for research in the wood glue industry is unknown. 3.2.5 Pharmaceutical industryThe Danish Association of the Pharmaceutical Industry contacted nine major pharmaceutical companies in Denmark (See Appendix 1). None of these reported any use of pure resorcinol or products containing resorcinol. However, resorcinol is known to be used in eye drops. One product, Resorcinol Ophtha, contains 1% of resorcinol and is sold in packagings with 10 ml. In total about 15 kg of resorcinol is used for eye drops annually in Denmark. 3.2.5.1 Fate of resorcinol in pharmaceuticals 3.2.6 Plastics industryLarge plastic manufacturing companies were contacted by the Danish Plastics Federation in order to obtain information regarding the use of resorcinol in plastic products (See Appendix 1). None of the companies reported production or use of pure resorcinol or products containing resorcinol. 3.2.7 Discussion of survey informationTable 3.6 below presents the information compiled by surveys in the Danish industries that reasonably can be assumed to be the main importers and consumers of resorcinol.

Table 3.6. Consumption of resorcinol (in kilos) in Danish industries in 2003, based on survey information. The survey shows that the consumption of resorcinol in binders and hardeners is less than when statistical information from the Product Register is used for estimation. There can be several reasons for this, the most probable being that the consumption pattern has changed over the years without notifying the Product Register. The survey also shows that there is a significant consumption of resorcinol in hair dye products. Although the consumption is estimated by extrapolation of statistical information on the EU level, the range (1000-1700 kg) is assumed to give a representative picture. Finally, the use in a certain pharmaceutical product was identified. The consumption of resorcinol in this product is assumed to be insignificant in relation to environmental exposure, but will for obvious reasons be a source of human exposure. The survey did not reveal any information regarding export of products containing resorcinol. Based on various statistical information and assumptions, an indication of the amounts of resorcinol in wood and rubber products being im- and exported is given in the appendices. 3.3 Summary and discussionInformation has been collected from statistical sources as well as by survey of relevant Danish industries. The information is summarised in Table 3.7, the minimum amounts given in the table being best case information from the industrial survey and the maximum amounts being combined statistical and survey information using the best possible level of detail.

Table 3.7. Minimum and maximum amounts (in kilos) of resorcinol imported for processing and use in Denmark It is noted that the maximum estimate is lower – about 5% - than the estimate based on statistical information. The difference can be ascribed to the different levels of detail of the information sources. The difference in minimum and maximum values for import of wood glue is primarily related to the content being reported in intervals, while the difference for rubber production reflects the differences between information from the industrial survey and the available statistical information. However, the range given in the table are judged to be fair estimates of minimum and maximum amounts for the flow of resorcinol in Denmark. 4 Exposure of humans and the environment4.1 Resorcinol as a chemical intermediate In this chapter, the information obtained from statistical sources and industrial surveys is used to estimate the environmental exposure and – where relevant – also human exposure. The environmental exposure is estimated in the form of emissions to air, water and soil from processes taking place in Denmark. This is done by using the calculation procedures and default values from the EU Technical Guidance Document for risk assessment (TGD). Human exposure from the use of hair dye products containing resorcinol is also estimated by using the procedures of the TGD. Finally, generation of waste with active resorcinol is estimated by using information from the users of resorcinol and resorcinol-containing products. The estimates are presented for each industrial and private application, allowing an identification of the most important leaks to the environment. 4.1 Resorcinol as a chemical intermediateIn 2002, two tons of resorcinol was imported to Denmark for use in chemical synthesis. It has not been possible to obtain information on the processes applied or the products being manufactured from resorcinol. Another 751 kg were imported for use in manufacturing of glue adhesives. Based on the methodology described in the Technical Guidance Document (TGD) for EU risk assessment, the emissions to air, wastewater and soil can be estimated, the main assumption being that the total of 2,751 kg is used as an intermediate in chemical synthesis. For chemicals with a vapour pressure < 1 Pa, the TGD assumes that there will be no emissions to air. When processing less than 1,000 tons per year, the fraction being released to wastewater is assumed to be 0.02, corresponding to 55 kg. The fraction emitted to soil is assumed to be 0.0001 of the processed amount, corresponding to 0.028 kg. There is no information on generation of waste in chemical synthesis. 4.2 Resorcinol in wood glueThe EU TGD does not contain information relating to manufacturing of wood products. In order to give an estimate of the emissions, it has therefore been assumed that the emission pattern is similar to that of curing agents used for thermosetting resins in the polymer industry. For this use category, a fraction of 0.075 (7.5%) is estimated to be released to air, corresponding to between 254 kg and 872 kg when low/high estimates from the industrial survey are used. The worst case estimate, assuming that 14 tons is used as wood glue, is that 1050 kg are emitted to air. A fraction of 0.00005 is assumed to be realeased with wastewater, corresponding to between 0.17 kg and 0.58 kg when low/high estimates from the industrial survey are used. The worst case estimate, assuming that 14 tons is used as wood glue, is that 0.7 kg is emitted to water. A fraction of 0.00001 is assumed to be released to soil, corresponding to between 0.03 kg and 0.12 kg when low/high estimates from the industrial survey are used. The worst case estimate, assuming that 14 tons is used as wood glue, is 0.14 kg being emitted to soil. In the production of laminated wood/plywood small amounts of glue containing resorcinol will inevitably be disposed. A small survey among laminated wood manufacturers found that specialised recirculation processes minimise the glue waste. In practice, there will only be spills from the inside of the glue containers. This is estimated to be 1% of the total amount (34-116 kg/worst estimate 140 kg) and is assumed to be disposed of as chemical waste to Kommunekemi. 4.3 Resorcinol in rubber adhesivesThere is no emission estimates for rubber production in the EU TGD. Production of thermosetting resins is assumed to cover the processes, and based on the EU TGD, the following fractions are assumed to be released to air, water and soil, respectively: A fraction of 0.075 (7.5%) is estimated to be released to air, corresponding to between 19.5 kg (survey estimate) and 292.5 kg (statistical estimate; worst case). A fraction of 0.00005 is assumed to be estimated with wastewater, corresponding to between 0.01 (survey) and 0.2 kg (worst case). A fraction of 0.00001 is assumed to be released to soil, corresponding to between 0.003 kg (survey) and 0.04 kg (worst case). The empty barrels with resorcinol adhesive will be disposed as chemical waste to Kommunekemi. It is estimated that 5% of the resorcinol is remaining in the barrels, corresponding to 13 kg and 195 kg, respectively, for survey and worst case estimate. 4.4 Resorcinol in hair dye productsResorcinol in hair dye products is not included in the statistical information. The estimates below are therefore low/high estimates from the industrial survey. In the EU TGD the default emission fraction values for cosmetics used privately are:

The default value for emissions via wastewater (80%) to municipal water treatment plants is assumed to be a fair estimate. Interviews with hairdressers reveals that any surplus colour will be rinsed from the mixing bowl and emitted to the waste water. The major uncertainty is probably the amount of active resorcinol in the emissions. According to Rastogi et al, 2003, the compounds in hair dyes react very quickly, and it is possible that almost all resorcinol will be reacted before being emitted. The above estimate is therefore assumed to be conservative. It is assumed that 5% of the active substances remain in the tubes in which they were delivered to the hairdresser. This corresponds to between 50 and 85 kg for low and high estimates, respectively. 4.4.1 Human exposure from use of hair dye productsIn theory, hairdressers have the largest potential for exposure to resorcinol in hair dye products. However, plastic or rubber gloves are always used in the hair dyeing process, and the dermal exposure is therefore assumed to be insignificant. Based on the default values in the EU TGD, this is also the case for airborne emissions, but it is mentioned that there is a potential for aerosol formation during the dyeing process. This has not been quantified. People having their hair dyed with products containing resorcinol are exposed to resorcinol through direct skin contact. According to the rules governing cosmetic products in the European Union (European Commission, 1999), the exposure shall be calculated using the assumption that the entire amount applied to the skin is absorbed. Furthermore, a partition coefficient between skin and hair of 0.9 has to be considered, i.e. that 10% of the total amount of hair dye is applied to the scalp. If it is assumed that the product contains 1% of resorcinol, and 60 grams (cm³) of hair dye is used in each dyeing process, the potential uptake can then be calculated to 60 mg per session. With a body weight of 60 kg, the potential uptake per kg body weight per hair dyeing session is 1 mg. It is remarked that the Cosmetics Directive permits a content of up to 5% resorcinol in hair dye products, and the potential uptake is in this case 5 g/kg body weight. However, the maximum content of resorcinol found in hair dye products on the Danish market in 2002 was 1.13%. 4.5 Resorcinol in pharmaceuticalsThe full amount of resorcinol applied to the human eye will be absorbed in the body, while the use in pharmaceuticals is assumed not to cause significant emissions to air, water or soil. It is remarked that there is a risk of resorcinol remaining after finishing of the treatment may be poured into the drain and accordingly be emitted with waste water. 4.6 Consumption as trace element and Unintended uses as contaminantResorcinol is known to be present in smoke from wood and cigarettes. Human exposure has been estimated by ASH in New Zealand (Action on Smoking and Health, www.ash.org.nz). A typical non-smoking service employee will inhale 123 ng of resorcinol in an 8 hour shift in a 300 m² area where there are 10 smokers smoking two cigarettes per hour and standard ventilation rates are applied. No further efforts have been devoted to calculate the total emissions of resorcinol from tobacco and wood smoke in Denmark. Resorcinol may be released to the environment in waste effluents associated with coal gasification and conversion, coal-tar production, and shale oil processing. The concentration of resorcinol in condensate water from a coal gasification plant in North Dakota, USA, ranged from not detected to 60 ppm over a two-year period. Resorcinol in concentrations of 1000 ppm was detected in wastewater from a synthetic coal conversion process. Information on such occurrences in Denmark has not been found. 4.7 Summary and discussion4.7.1 Emission estimatesAs described in the previous chapter there are some inconsistencies between the statistical information and the information obtained by surveys. In order to give the best overview it has been chosen to present the information in two ways, i.e. a worst-case estimate and a “survey” estimate. In the worst case estimate, the amounts being reported in statistical sources is supplemented with the information from the surveys, e.g. regarding the use in hair dye products. The survey estimate presents the estimates of environmental exposures, based alone on survey information. In the survey, ranges are given for wood glue and hair dyes. Accordingly, a low/high estimate has been established and reported in the previous sections. In the presentation below, the low estimate from the survey is combined with the high (worst case) estimate from the combined statistical and survey information. Together, they are assumed to give a realistic figure for the range of emissions of resorcinol to different compartments of the environment.

Table 4.1. Minimum and maximum estimates(in kilos) of emission of resorcinol in Denmark. 4.7.2 Waste estimatesThere is very little information available on generation of waste containing resorcinol. The information is summarized in Table 4.2 below.

Table 4.2. Generation of waste containing resorcinol in Denmark 1 Chemial waste disposed at Kommunekemi Besides the amounts generated during production and processing of resorcinol, estimates have been established regarding the amounts of resorcinol in final products. Eventually, all wood products with resorcinol are assumed to be incinerated with energy recovery. Rubber products are assumed to be incinerated or landfilled, depending of the disposal route for the products they are part of. The figures are presented in appendices, the reason being that the resorcinol in the products are strongly bonded in a matrix, if not fully reacted. The potential for release of resorcinol to the environment via waste is therefore very small. 5 Environmental and health hazards of resorcinol5.1 Toxicity and ecotoxicity of resorcinol 5.1 Toxicity and ecotoxicity of resorcinol5.1.1 Classification and labellingResorcinol is classified by the EU and the Danish authorities as harmful (Xn), irritant (Xi) and dangerous for the environment (N). The following risk and safety phrases apply:

5.1.2 Human toxicityResorcinol is harmful if swallowed, inhaled or absorbed through skin and causes eye and skin irritation. The compound is irritating to mucous membranes and upper respiratory tract. Depending on the intensity and duration of exposure, effects may vary from mild irritation to severe burns. Cutaneous application of solutions or salves containing from 3 to 25% of the compound may result in local hyperemia, itching, dermatitis, corrosion, and the loss of superficial layers of the skin. The substance may cause effects on the blood, resulting in formation of methaemoglobin. The effects may be delayed and medical observation is indicated. (HSDB, 2003). Several cases of fatal poisoning following skin contact with resorcinol have been reported (Jensen, 2001). Resorcinol is regarded as goitrogenic, causing hypo-thyroidism following persistent exposure, e.g. through intake of drinking water polluted with resorcinol from coal gasification and shale oil production, or through use as topical ointment on skin lesions. It is this effect that has been shown by epidemiological studies and used as evidence for listing resorcinol as a category 1 substance (substance of high concern) in the EU list of substances for further evaluation of their role in endocrine disruption (BKH, 2000). 5.1.3 Animal toxicityResorcinol is moderately toxic in animal tests. The following toxicity values have been reported (HSDB, 2003): LD50 (rat, oral): 301 mg/kg; 980 mg/kg Lethal oral doses have been reported to approx. 0.37 g/kg for rats and guinea pigs, and approx. 0.75 g/kg for rabbits. In an inhalation toxicity test, aerosol (resorcinol-water) concentrations as high as 7800 mg/m³ for a 1-hour period and 2800 mg/m³ for an 8-hour period caused no deaths or lesions attributable to inhalation of the aerosol at gross autopsy. Application of 0.1 g of resorcinol into the eyes of rabbits caused discomfort, conjunctivitis and corneal ulcerations, which were not reversible. Application of 0.5 g of resorcinol moistened with saline to intact or abraded skin of rabbits for up to 24 hours caused reactions varying from no irritation to moderate irritation of the intact skin, and from no irritation to necrosis of the abraded skin. 5.1.4 CarcinogenicityIARC (1999) has evaluated that no epidemiological data relevant to the carcinogenicity of resorcinol were available. There is inadequate evidence in experimental animals for the carcinogenicity of the compound. The overall evaluation from IARC is that resorcinol is not classifiable as to its carcinogenicity to humans and the compound is placed in Group 3. 5.1.5 Endocrine disruptionResorcinol has been assessed at an expert panel meeting as a step in the procedure towards the establishment of a priority list of substances for further evaluation of their role in endocrine disruption (BKH, 2000). The expert panel concluded that human health relevant endocrine disruption data were of category 1, i.e. that at least one study providing evidence on endocrine disruption in an intact organism was identified. In practice, a study documenting changes in goitrogenic activity in workers (decreased T4/T3 metabolism) was used as evidence. Wildlife endocrine disruption data were evaluated as category 3, i.e. there was no scientific basis for inclusion in the list or no data. Due to the potential for human exposure through use as a pharmaceutical or cosmetic on skin and by wood or cigarette smoke inhalation, resorcinol is prioritised by the expert panel as being af substance of high concern. 5.1.6 Environmental fate and exposureResorcinol is readily biodegradable and do not bioaccumulate. If released to air, the vapour pressure (4.9 * 10-4 mm Hg at 25°C) indicates that resorcinol will exist solely as a vapour in the ambient atmosphere. Vapour-phase resorcinol will be degraded in the atmosphere by reaction with photochemically produced hydroxyl radicals, the half-life for this reaction is estimated to be 1.9 hours. If released to soil, resorcinol is expected to have a high mobility based upon an estimated coefficient of adsorption for substance in soil (Koc) of 65. Biodegradation is expected to an important environmental fate process for resorcinol. Complete degradation occurred in 8 days as determined by a 100% UV absorbancy loss. The half-life of resorcinol in an aerobic screening test ranged from 0.16 to 0.24 days using activated sludge. An estimated bioconcentration factor (BCF) of 2 suggests that the potential for bioaccumulation in aquatic organisms is low. Hydrolysis is not expected to an important environmental fate process due to a lack of hydrolysable functional groups. 5.1.7 EcotoxicityResorcinol is toxic to aquatic organisms. HSDB (2003) quotes a number of LC50-values from K. Verschuerens “Handbook of environmental data of organic chemicals” from 1983. The conditions of the bioassys were not specified for any of the following values:

The AQUIRE database gives additional information for daphnia (AQUIRE, 2003): LC50, daphnia: 0.25-0.9 mg/l (96 h) 6 Alternatives / substitutes6.1 Wood adhesives 6.1 Wood adhesivesResorcinol and phenol-resorcinol-formaldehyde glues are primarily used as special purpose adhesives in the wood industry, being more expensive than other glues. They are not widely used for plywood manufacture. Rather, they are used as assembly glues in solid wood products, which must resist exposure to the weather and to water, such as glued laminated wood beams and forklar I-joints (Eckelmann, n. y.). The properties of resorcinol are high in both dry and wet strength. They are very resistant to moisture and damp conditions, and more resistant to high temperatures and chemical ageing than wood. They cure at room temperatures on most species of wood. The United Soybean Board (USB) – an interest organisation for US soybean farmers - have established a market opportunity summary for soy-based wood adhesives. Based on research at Battelle, two segments/applications for wood adhesives containing resorcinol have been identified as emerging markets for soy-based adhesives. One application is glue-laminated lumber with a thickness of 2 inches or less. The other is I-joists, load-bearing structural members consisting of a top and bottom flange adhered to a vertical web made of OSB (oriented strand board) or plywood. In both cases, soy-based glues can be used as extenders to the resorcinol-containing glue. According to USB, a system with hydrolysed soy protein and phenol-resorcinol-formaldehyde will achieve faster cure rates and improved economics. From a health and environmental point of view, substituting either element in a phenol-resorcinol-formaldehyde glue is seen as advantageous, as there are no significant impacts associated with soy protein. It is however remarked, that the glue will still contain the elements, the only difference being that smaller amounts are used in the glueing process. There is no information regarding Danish or European investigations of the possibilities of using soy protein for the above (or similar) applications. 6.2 Rubber adhesivesThe use of resorcinol as an adhesive in production of rubber products like tires and conveyor belts can only be mapped to a very limited degree. It is assumed that it is used in its pure form or in combination with for example silisic acid and hexamethylentetraamin to obtain good adherence to steel cord in tires (Ahlbom and Duus, 1994). Traditionally, the rubber industry is rather secretive about its chemicals, manufacturing processes and products. There is little doubt that resorcinol can be substituted in many products, but the substitutes are virtually unknown. The US EPA thus states in a report on presumptive maximum achievable control technology in the rubber tire manufacturing source category that “… the tire manufacturing industry has indicated that tire manufacturing processes are, in large part, proprietary in nature. In particular, different companies use different formulas in the manufacture of tires. Types and quantities of materials, including solvents, vary, and are closely-guarded trade secrets…” (US EPA, 1998). 6.3 Hair dyeing productsResorcinol was found in 15 out of 18 hair dyeing products on the Danish market in concentrations from 0.002 to 1.3 %. It is used as a coupler in the colouring system, but it has not been possible to determine the function of resorcinol more precisely in the current study. It has not been possible to find information on possible substitutes. 6.4 Other applicationsAlternatives for and substitution of resorcinol in other applications is not discussed here. 7 ReferencesAhlbom, J. & Duus A. (1994). Nya hjulspår – en produktstudie af gummidäck. Rapport fra kemikalieinspektionen (KEMI) 6/94. AQUIRE (2003): ECOTOX – Ecotoxicological database. http://www.epa.gov/ecotox/quicksearch.html. ASH New Zealand. Secondhand tobacco smoke – the facts. (www.ash.org.nz/doc/l-doc/0000255e.html) BKH (2000): BKH Consulting Engineers, TNO Nutrition and Food Research: Towards the establishment of a priority list of substances for further evaluation of their role in endocrine disruption – preparation of a candidate list of substances as a basis for priority setting. Final Report to the European Commission DG ENV. Project Number M0355008, Delft, The Netherlands. Chen, J., et al (2001). Substrate-coating interaction in coated fabrics. National Textile Center Annual Report 2001, F00-D06. (http://www.ntcresearch.org/pdf-rpts/AnRp01/F00-D06.pdf) COLIPA (2003): The European Cosmetic Toiletry and Perfumery Association. CYTEC (without year). Provisional Product Bulletin CYREZ CRA-138L. Novel technology for improved adhesion performance between reinforcing substrates and elastomeric materials (for tires and mechanical rubber goods). www.cytec.com Eckelmann, C.A. (uden år). Brief survey of wood adhesives. Forestry and Natural Resources 154. Purdue University, Cooperative Extension Service, West Lafayette, Indiana, USA. European Commission (1999). The rules governing cosmetic products in the European Union. Volume 3. Guidelines Cosmetic products. Notes of guidance for testing of cosmetic ingredients for their safety evaluation. 1999 Edition. Frydendal, J. (2003): Incineration model. dk-TEKNIK ENERGY & ENVIRONMENT. Hajduk, F. & Kishi, A. (2001): Resorcinol, Chemical Economics Handbook Report. HSDB, (2003): Hazardous Substances Data Bank. http://toxnet.nlm.nih.gov/cgi-bin/sis/htmlgen?HSDB. IARC (1999): Monographs on the evaluation of the carcinogenic risk of chemicals to man. Geneva: World Health Organisation. International Agency for Research on Cancer, 1972-present. (Multivolume work) p. V71 1128. Jensen AA (2001). Fokus på farlige stoffer. Catechol og resorcinol. Arbejdsmiljø 4: 2001. Kvist, K. E., Fox, M. & Kofoed, C. J. (2000): Brancheanalyse af miljømæssige forhold i træ- og møbelindustrien. Environmental Project No. 561, Danish Environmental Protection Agency. Lassen, C. & Hansen, E. (2000): Paradigm for Substance Flow Analysis, Environmental Project No. 577. Danish Environmental Protection Agency. NTP (2003): NTP chemical repository p-nitrotoluene. http://ntp-db.niehs.nih.gov/NTP_Reports/NTP_Chem_HS_HTML/NTP_MSDS/Hs_108-46-3.html. Rastogi,S.C., Worsøe,I.M. & Jensen,G.H (2003). Precursors of oxidative hair dyes in hair colouring formulations. Arbejdsrappor fra DMU, nr. 175, 2003. RTF (2000): Resorcinol: A case story in managing toxicological issues in the regulatory environment. Poul Ashford, Resorcinol Task Force. Spectrum laboratories (2003): Chemical Fact Sheet. http://www.speclab.com/compound/c108463.htm SPIN (2003): Substances and Products in the Nordic Countries. Statistics Denmark (2003). Varestatistikken and Udenrigshandelsstatistikken. http://www.statistikbanken.dk. Ullmann's (2002): Ullmann's Encyclopedia of Industrial Chemistry. United Soybean Board (2002). Market Opportunity Summary. Soy-based Wood adhesives. February 2002. http://www.unitedsoybean.org/ USEPA (1998), Preliminary industry characterization: Fabric printing, coating, and dyeing. US EPA Office of Air Quality. Planning and Standards, RTP, North Carolina. Draft, July 1998. USEPA (1998). Presumptive maximum achievable control technology in the rubber tire manufacturing source category. U.S: Environmental Protection Agency. Office of Air Quality Planning and Standards. Emission Standards Division. Policy Planning and Standards Group. July 1998. http://www.epa.gov/ttn/oarpg/t3/reports/p_mact5.pdf 8 AppendicesAppendix 1 - Companies contacted in the survey Appendix 1 - Companies contacted in the surveyContacted companies in the pharmaceutical industryNYCOMED DANMARK A/S Contacted companies in the plastic industryPolimeri Europa Norden Contacted companies in the rubber industryDansk Gummi Teknik A/S Contacted companies in the wood glue industryFrede Andersens fabriker A/S Appendix 2: Amount and fate of laminated wood and plywoodBesides the produced and imported wood glue used in Denmark there will also be import of wood glue, and hence also import of resorcinol, via import of laminated wood and plywood. The flow of resorcinol via laminated wood and plywood can be estimated based on figures for the import of resorcinol via glues, the total revenue for the Danish production of laminated wood and plywood as well as the import/export of laminated wood and plywood.

The ultimate fate of wood products used in Denmark is assumed to be incineration with energy recovery. Appendix 3: Amount and fate of tiresIn the tire industry resorcinol is used as bonding agent for obtaining good adhesion between fabric plies and tire rubber. The bonding agents are mixed directly into the rubber compound. Resorcinol is used in tires to bond synthetic fabrics in the rubber. Resorcinol is part of a dry system - a technique where the bonding agents are mixed directly into the rubber compound to obtain good adhesion between fabric plies and tire rubber. If it is assumed that all the resorcinol used in the rubber industry is used in tire manufacturing, the total amount of resorcinol in tires can be calculated by linear interpolation, based on the number of cars in the world compared with the number of cars in Denmark. It should be emphasised that this is a conservative estimate, since it is known that some resorcinol in the rubber industry is used for specialised rubber products like conveyer belts. Global consumption of resorcinol in the rubber industry: 23,000 tons/year It is uncertain whether it is special types of tires that contain resorcinol. Therefore the tires imported to Denmark may contain more or less resorcinol than the calculated amounts. It has been estimated that the resorcinol import to Denmark via tires could be 25 % below or above the calculated figure. This means that the estimated import of resorcinol via tires will be between 43.5 and 72.5 tons. Based on import/export figures from year 2002 and the calculated interval for the amount of resorcinol imported via tires the average content of resorcinol in Danish tires can be estimated.

Fate of resorcinol contained in tires Experience shows that about 17% of the tires are worn off and ends up around the roads (Association for Tire Specialists in Denmark, 2003). Some of this may be reacted resorcinol, but the exposure of the environment is assumed to be insignificant. The majority of the remaining 83% are collected. In 1995 the Environmental Protection Agency and a number of Danish organisations agreed to collect used tires from private cars, trucks and motorcycles. Later the agreement was extended to include all motorised vehicles. The aim of the agreement is to ensure collection and recycling of tires that are disposed in Denmark. This avoids deposition at landfills and ensures a sensible resource utilisation, where recycling has a higher priority than incineration with energy recovery. In year 2001 the collection percentage was 97%, and hence almost all tires part of the agreement were collected. Out of 43,328 tons tires that were part of the agreement 41,208 tons were collected. Of these, 87% were either used to produce rubber powder or incinerated, while about 10% were rethreaded (Affaldsstatistik 2001, Miljøstyrelsen). Distribution figures from year 2000 shows that out of the total collected amount, 15% is used directly for rethreading, 16% is reused and 60% is recycled for an unspecified purpose, while the remaining 9% are incinerated with energy recovery (www.mst.dk/affald/01030300.htm) From this distribution and the above calculations an estimate of the total flow of resorcinol contained in Danish tires can be established. Table 8-1 below summarises the fate of the resorcinol flow in tires.

Table 8-1: Flow of resorcinol via flow of tires. The disposal routes of the collected tires implies that all resorcinol contained in the tires will either be incinerated or remain strongly bonded in a matrix in recycled products and accordingly not be released to the environment as pure resorcinol. There is, however, a small potential for resorcinol release during the regrinding process. This cannot be quantified, but is assumed to be insignificant.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||