|

Environmental project no. 1099, 2006 Development of cleaner products in Berendsen's international product chainsContents3 Overcoming barriers in environmental product development

4 Product Development - Process and Results Appendix A: Presentation at LCM 2005 Appendix B: Conference: Product Oriented Environmental Work [Danish] Appendix D: Rent miljø er en konkurrencefordel [Danish] Appendix E: Rent miljø handler også om sæbe [Danish] Appendix F: Products of the future secure Berendsen's position as market leader in Denmark PrefaceThe intention of this report is to inspire and guide companies to develop cleaner products and bring them on the market. It is the result of a demonstration project carried out in cooperation between Berendsen Textil Service A/S, FORCE Technology and EcoForum to demonstrate with practical experience how cleaner products can be developed in cooperation with suppliers – or the whole value chain. You do not have to be environmentally concerned to benefit from environmental product development projects. When working with your products, you will probably also find some other improvement options leading to e.g. higher quality or lower costs. During the project, different communication activities have been carried out to disseminate the experience and good advice developed during the project period. Hence, this report is only a part of the communication, summing up the project and main conclusions. However, the report also includes a short description of the other communication activities. All the development projects have been carried out on the hygiene product range of Berendsen, but the lessons learnt are universal for environmental product development of products. Jeppe Frydendal Søren Mann Andersen Summary and Conclusions1.1 Background and purposeWhen standing in the supermarket choosing between two or more products that can fulfil the same function, there is a number of factors which influence your choice. This is also the case when a company is about to select a supplier. Here the following parameters typically apply:

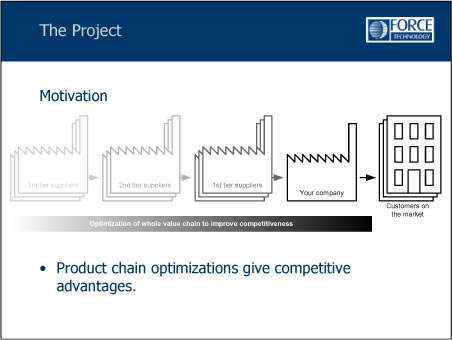

Figure 1. There are many considerations when choosing between product A and product B. All the above parameters are a result of the interaction in the whole product chain – from cradle to grave. Your choice in the supermarket can thus be seen as a competition between two product chains more than between two companies.

Figure 2. When two companies (A and B) compete on the market – it is in fact a competition between two product chains. Optimizing the product chains of the company in the whole life cycle can thus give a better competitiveness.

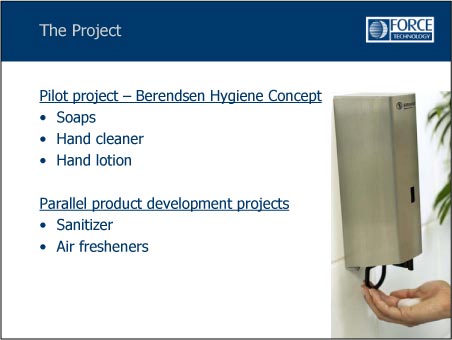

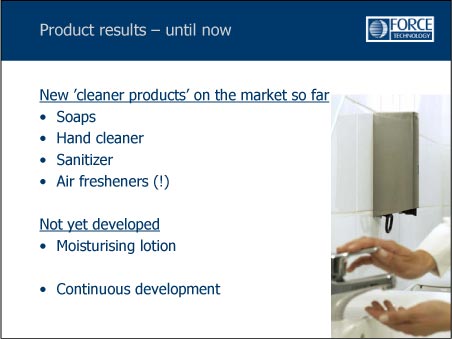

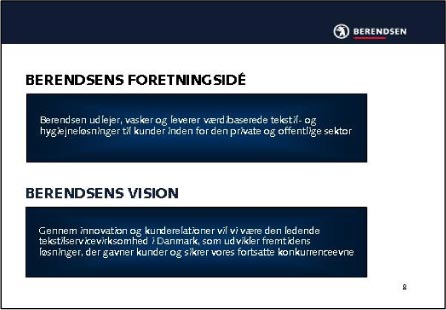

Figure 3. Cooperation in the value chain to improve the competitive parameters for the final product/service results in better competitiveness. This is one of the motivational factors for the players in the value chain to cooperate on optimization of the value chain from cradle to grave. In the project, focus has been on this product optimization in the case of Berendsen Textil Service’s supply of soaps and creams, which are delivered as a supplement to the textile service. The purpose of the project has not only been to carry out concrete developments. It has equally been to communicate the experience to other interested companies and to inspire them to start development of cleaner products themselves – in Denmark as well as internationally. Environment is not the most significant sales parameter for Berendsen Textil Service A/S, but still one of major significance. At the same time, the environment is one of the points where Berendsen has an opportunity to differ from its competitors – and when all things are equal then the environment might be the decisive factor in a sale. 1.2 The studyFORCE Technology and Berendsen Textil Service A/S, in cooperation with Berendsen’s suppliers, have completed a number of development procedures to introduce more environmentally friendly and healthy products on the market. Focus has been on Berendsen’s hygiene products which, among other things, include soap, hand cleaner, lotion, sanitizer liquid and similar cosmetic and chemical products. The products are delivered as a supplement to Berendsen’s textile service concepts with laundry and rental of textiles. The barriers encountered during the project are described and the information on how the barriers were overcome will be especially interesting for other companies wishing to offer cleaner products to their market. The project has been embedded in Berendsen’s sales and marketing division and the results have been integrated in the sales organization so Berendsen can actively make use of the competitive advantages connected to the newly developed products. 1.3 Main conclusionsThe project shows that it is possible to develop cleaner products for the market in cooperation with one’s suppliers and to achieve positive response from the market. It has turned out that it is possible to overcome most of the substantial barriers to development by being persistent and patient. A consequence of this is that it should be borne in mind that development projects take a long time. Examples of barriers overcome in the process are:

The experience from Berendsen shows that as a starting point it is easier to cooperate with a supplier in Denmark about development than a supplier from abroad and outside Europe, and it is often necessary to provide the supplier with a large amount of knowledge and competences in relation to, for instance, relevant legislation in the EU to achieve success. It is no wonder that this is the reality in light of the fact that the biggest barrier is in companies’ understanding of the demands of the market. A company in Denmark knows the Danish customers’ preferences, while a business partner in southern Europe wants his products to meet the demands of his own market. In southern Europe “clean” often means that it smells good (of perfume). This is in direct conflict with the demand for a perfume-free product which often can be found in the Nordic countries. At a related after-work workshop the participants from a number of Danish companies concluded that the customers’ demands for environmentally friendly products can be handled positively as an input to innovation. Minutes of the after-work workshop are enclosed as Appendix C. 1.4 Project results1.4.1 New clean products on the shelvesDuring the project Berendsen developed and introduced 11 new products with a smaller impact on the environment and health. However, some of the products were not developed as a part of the project, but in parallel with the development project. However, the total experience is communicated to get a broad coverage of the challenges which can be encountered in the cooperation with the suppliers. 1.4.2 Barriers are overcomeBased on the experience from Berendsen, the recipe for success is, as mentioned earlier, patience and persistence in relation to suppliers. However, there are some cases where barriers cannot be overcome on their own and here it might be necessary to find another supplier/business partner. In one case Berendsen got help from the legislation, which put pressure on the supplier so that he had to change his product anyway. 1.4.3 Legislation and tools help you on the wayExactly legislation can be a partner in development projects. Legal requirements on transparency in relation to constituents in cosmetic products give a far better starting point than in the case of chemical products where the producers are often very secretive about information. Harmonized EU legislation makes it easier to cooperate with international suppliers about development of products. In future, the new EU requirements in relation to specification of allergy-causing perfume substances will help Berendsen who, for a long period, have been working on getting their suppliers to phase out these 26 substances in products with perfume where there is a risk of getting into contact with the product. Ecolabelling criteria can also give inspiration on how new products can be combined so impact on the environment and health is reduced. At the same time the chemical list from the ecolabelling scheme gives much valuable information about individual substances. However, experience from Berendsen’s products shows that the ecolabelling criteria sometimes give too little consideration to life cycle thinking. For instance it can be proved that Berendsen’s new foam soap without perfume and colour burdens the environment far less than an average ecolabelled cream soap for each hand wash. Nevertheless Berendsen’s foam soap cannot be assigned the ecolabel because the criteria do not relate the environmental impact to the functional unit, i.e. in relation to the number of times you can wash your hands with the soap. Berendsen’s Code of Conduct shows suppliers from the beginning of a relationship that being a supplier to Berendsen involves some obligations – also within the environment. With this tool Berendsen ensures that suppliers will not be shocked when Berendsen starts to clarify environmental improvements of products. Berendsen has many suppliers – and it is not possible to keep a close dialogue with all. Therefore, Berendsen’s suppliers are regularly evaluated with the internet-based supplier evaluation tool – Supplier-e-valuation® - from FORCE Technology. 1.4.4 The sales staff are equippedBerendsen has created an intranet portal for sales representatives where they can always find relevant and updated documentation in the form of product sheets, user’s manual from the suppliers, perfume declarations and similar. At the same time the intranet portal gives brief background information for each product and concrete sales arguments including environmental and health aspects. In this way Berendsen expects that the efforts to develop cleaner products can result in an even greater plus on the bottom line 1.4.5 The development does not stop hereFor Berendsen, development of a new cleaner product and introduction on the market does not mean that the work is done. They are always looking for further improvements of the products in relation to market trends and in relation to new technical knowledge. This means that even if this project ends, Berendsen’s customers can also expect new products with improved environmental and health profiles in the future. Sammenfatning og konklusioner1.5 Baggrund og formålNår du står i supermarkedet og skal vælge mellem to eller flere produkter, der kan opfylde samme funktion, så er der en lang række forhold, som spiller ind på dit valg. Det samme gælder, når en virksomhed skal vælge en leverandør. Her er det typisk følgende parametre, der gør sig gældende:

Figur 3. Der er mange overvejelser, når man skal vælge mellem produkt A og produkt B. Alle de nævnte parametre er et resultat af samspillet i hele værdikæden – fra vugge til grav. Således kan dit valg i supermarkedet ses som en konkurrence mellem to produktkæder mere end bare mellem to virksomheder.

Figur 4. Når to virksomheder (A og B) konkurrerer på markedet – er det i virkeligheden en konkurrence mellem to produktkæder. At optimere sine produktkæder i hele livscyklus kan således give bedre konkurrenceevne.

Figur 5. Samarbejde i værdikæden for at forbedre de konkurrencemæssige parametre for det endelige produkt/den endelige service medfører en bedre konkurrenceevne. Dette er en af motivationsfaktorerne for aktørerne i værdikæden til at samarbejde om at optimere værdikæden fra vugge til grav. I projektet har fokus været på denne produktoptimering og casen har været Berendsen Textil Services leverance af sæber og cremer, der leveres som et supplement til tekstilservice-ydelsen. Formålet med projektet har ikke bare været, at gennemføre konkrete udviklingsforløb. I lige så høj grad har det været at formidle erfaringerne til andre interesserede virksomheder og inspirere dem til selv at komme i gang med udvikling af renere produkter – i Danmark såvel som internationalt. Miljø er ikke den væsentligste salgsparameter for Berendsen Textil Service A/S, men dog stadig af væsentlig betydning. Samtidig er netop miljø et af de steder, hvor Berendsen har mulighed for at adskille sig fra sine konkurrenter – og når alt andet er lige, så kan miljøet gå hen og blive tungen på vægtskålen i et salg. 1.6 UndersøgelsenFORCE Technology og Berendsen Textil Service A/S har i samarbejde med Berendsens leverandører gennemført en række udviklingsforløb for at bringe mere miljø- og sundhedsvenlige produkter på markedet. Fokus har ligget på Berendsens hygieineprodukter, der blandt andet omfatter sæbe, håndrens, lotion, sanitizervæske og tilsvarende kosmetiske og kemiske produkter. Produkterne leveres som supplement til Berendsens tekstilservicekoncept med vask og udlejning af tekstiler. De barrierer, vi har mødt undervejs, er beskrevet, og især oplysningerne om hvordan barriererne blev overvundet vil være interessant for andre virksomheder, der selv ønsker at udbyde renere produkter til deres marked. Projektet har været forankret i Berendsens salgs- og marketingdivision, og som afrunding på projektet er resultaterne integreret i salgsorganisationen, så Berendsen aktivt kan gøre brug af de konkurrencemæssige fordele, der er ved de nyudviklede rene produkter. 1.7 HovedkonklusionerProjektet viser, at det er muligt at udvikle renere produkter til markedet i samarbejde med sine leverandører og opnå positiv respons fra markedet. Det har vist sig, at det er muligt at nedbryde de fleste af de væsentlige barrierer for udvikling ved at være vedholdende og tålmodig. En konsekvens af dette er, at man skal regne med, at udviklingsprojekter tager lang tid. Eksempler på barrierer, der er nedbrudt undervejs, er:

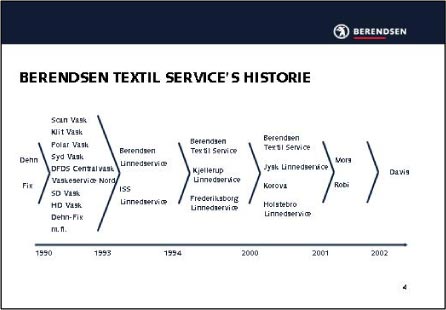

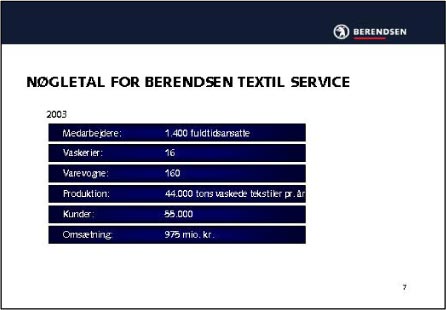

Erfaringerne fra Berendsen viser, at det som udgangspunkt er nemmere at samarbejde med en leverandør i Danmark om udvikling end i udlandet, og går man uden for Europa, er man ofte nødt til at forsyne leverandøren med en stor portion viden og kompetencer i forhold til f.eks. gældende lovgivning i EU for at få succes. Det er ikke så underligt, at det forholder sig sådan, når man tænker på, at den største barriere ligger i virksomhedernes syn på markedets behov. En virksomhed herhjemme kender selv de danske kunders præferencer, mens f.eks. en samarbejdspartner i Sydeuropa ønsker at lade sine produkter leve op til deres markeds krav. Ofte betyder ”rent” i Sydeuropa, at det dufter godt (af parfume). Det er i direkte konflikt med ønsket om et parfumefrit produkt, som man ofte kan opleve i Norden. På en tilknyttet gå-hjem-workshop konkluderede de deltagende personer fra en række danske virksomheder blandt andet, at kundernes krav om miljørigtige produkter kan håndteres positivt som et input til innovation. Referat fra workshoppen er vedlagt som bilag C. 1.8 Projektresultater1.8.1 Nye rene produkter på hylderneUnder projektforløbet har Berendsen udviklet og lanceret 11 nye produkter med lavere belastning af miljø og sundhed. En del af produkterne er dog ikke udviklet som en del af projektet, men er kørt som sideløbende udviklingsforløb. Imidlertid er det de samlede erfaringer, der formidles for at få en bred dækning af de udfordringer, man kan støde på i samarbejdet med leverandørerne. 1.8.2 Barrierer nedbrydesBaseret på erfaringerne fra Berendsen er opskriften på succes, som tidligere nævnt, tålmodighed og vedholdenhed i forhold til leverandørerne. Imidlertid er der nogle tilfælde, hvor barrierer ikke kan nedbrydes ved egen kraft, og her kan det være nødvendigt at gå ud og søge en anden leverandør/samarbejdspartner. I et enkelt eksempel fik Berendsen hjælp af lovgivningen, der pressede leverandøren, så denne alligevel skulle lave om på sit produkt. 1.8.3 Lovgivning og værktøjer hjælper dig på vejNetop lovgivning kan være en god medspiller i udviklingsprojekter. Lovkravet om gennemsigtighed i forhold til indholdsstoffer i kosmetiske produkter giver et langt bedre udgangspunkt, end det er tilfældet for kemiske produkter, hvor producenterne ofte holder informationerne tæt ind til kroppen. Harmoniseret EU-lovgivning gør det nemmere at samarbejde med internationale leverandører om udvikling af produkter. De nye EU-krav i forhold til angivelse af allergifremkaldende parfumestoffer vil fremover være en hjælp for Berendsen, der længe har arbejdet for, at leverandørerne skulle udfase disse 26 stoffer i produkter med parfume, hvor der er en risiko for at komme i kontakt med produktet. Miljømærkekriterier kan også give inspiration til, hvordan nye produkter kan sammensættes, så belastning over for miljø og sundhed mindskes. Samtidig giver kemikalielisten fra miljømærkeordningen en række værdifulde oplysninger om enkeltstoffer. Imidlertid viser erfaringerne fra Berendsens produkter, at miljømærkekriterierne sommetider tager for lidt hensyn til livscyklustankegangen. F.eks. kan det dokumenteres, at Berendsens nye skumsæbe uden parfume og farve for hver håndvask belaster miljøet langt mindre end en gennemsnitlig miljømærket cremesæbe. Alligevel kan Berendsens skumsæbe ikke få miljømærket, fordi kriterierne ikke relaterer miljøbelastningen til den funktionelle enhed, altså sætter den i forhold til antallet af gange, man kan vaske hænder med sæben. Berendsens Code of Conduct viser leverandørerne fra starten af et forhold, at det at være leverandør til Berendsen medfører visse forpligtigelser – også på miljøområdet. Med dette værktøj i hånden sikrer Berendsen, at det ikke kommer som et chok, når Berendsen begynder at konkretisere i forhold til miljøforbedringer af produkter. Berendsen har mange leverandører – og det er ikke dem alle, hvor det er muligt at opretholde en tæt dialog. For løbende at kunne følge op på leverandørerne og motivere dem til at forbedre sig, har Berendsens det internetbaserede leverandørvurderingsværktøj - Supplier-e-valuation® - fra FORCE Technology. 1.8.4 Sælgerne bliver klædt påPå baggrund af projektet opbygger Berendsen en intranetportal til sælgerne, hvor de altid vil kunne finde relevant og opdateret dokumentation i form af produktblade, leverandørbrugsanvisninger, parfumedeklarationer og lignende. Samtidig vil intranetportalen for hvert produkt give en kort baggrundsinformation og angive konkrete salgsargumenter, der også inkluderer miljø- og sundhedsaspekter. På denne måde forventer Berendsen, at indsatsen med udvikling af renere produkter kan skabe et endnu større plus på bundlinien. 1.8.5 Udviklingen stopper ikke herFor Berendsen er det at udvikle et nyt renere produkt og lancere det på markedet ikke ensbetydende med, at arbejdet er gjort. De leder altid efter yderligere forbedringer af produkterne i forhold til tendenser på markedet såvel som i forhold til ny faglig viden. Det betyder også, at selvom projektet slutter her, så kan Berendsens kunder også i fremtiden forvente nye produkter med forbedret miljø- og sundhedsprofil. 2 Introduction and MotivationSophus Berendsen A/S has been one of the pioneer companies in Denmark concerning product/service orientation of environmental work. In 2002 Sophus Berendsen A/S was acquired by the Davis Service Group plc. and most of the corporate functions, including the environmental department, were closed down and responsibility transferred to the national subsidiary companies. For the Danish subsidiary company - Berendsen Textile Service A/S – the changes meant that they could no longer get support for environmental work from the parent company. Today environmental work is an integrated part of the different departments of Berendsen Textile Service A/S. Environmental product development projects are anchored in the sales and marketing division of the company. 2.1 Motivation for environmental product developmentThere are different reasons for Berendsen and their suppliers to be active in product development.

Figure 6. Berendsen has many different motivations to participate in development of cleaner products 2.1.1 Cooperation on optimizing the value chainOne important driver to work with development of cleaner products in product chains relates to the concept of value chain thinking.

Figure 7. There are many considerations when choosing between product A and product B. When you are choosing between two products in the supermarket, there are a lot of important parameters like the price and quality that you probably use. For a company selecting a supplier or a product the situation is quite similar. Some typical competitive parameters in business-to-business relations are:

All these parameters are influenced through the value chain. An example is that if your supplier is not able to deliver the components that you use to produce your product within a certain time, then you cannot produce and deliver your products to the customers in time. Hence, competition on a market is a competition between two or more value chains and not only two or more companies. Therefore, all companies in a value chain share the same interest - to optimize the whole value chain to be competitive. This gives an incentive for the supply chain of a company to adapt to the requirements of the final consumer.

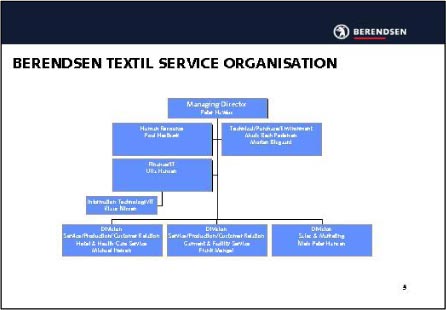

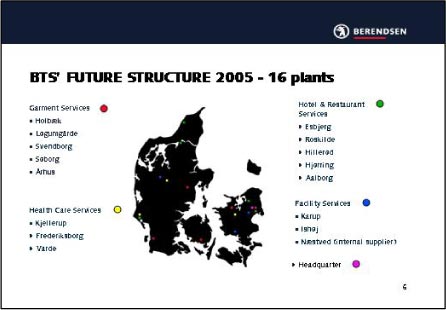

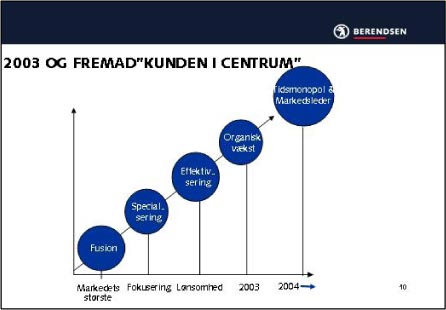

Figure 8. Cooperation in the value chain to improve the competitive parameters for the final product/service yields better competitiveness. This is a motivation to cooperate on optimizing the value chain as a whole. 2.1.2 Be market leaderBerendsen Textile Service A/S is the biggest textile service company in Denmark, with 19 service centres and about 1,500 employees. At Berendsen they see themselves as the market leader, which means that they want to stay ahead of the competitors and the legislation. In relation to development of cleaner products, Berendsen does not want to let the legislation set their product standard, but wants to meet the present and future needs and requirements of their customers. 2.1.3 Avoid bad reputationToday the tendency is that, as a company, you are held responsible for the actions of your suppliers. The pressure is high if you have a well-known brand and are located in the value chain close to the end consumer. A good example of this is Nike. In 1996 in the CBS TV programme 48 hours, the very poor working conditions for workers at some Asian Nike suppliers were revealed. Nike got all the blame and bad reputation and based on this the company implemented a code of conduct to be met by all suppliers. Today Nike has become more open and in 1995 they revealed information about their supplier factories. Berendsen, of course, is not as strong a brand as Nike, but still the brand is well-known on most of the markets where they are present*.

Figure 9. Berendsen logo since 1998 - a modern simplification of the original bear logo for Sophus Berendsen A/S founded in 1854. In Denmark there is a lot of focus in the media on consumer protection, and consumer organizations test different products to reveal problems. Often you read about problems with allergies from cosmetics. During the project, headlines such as “keep your hands off the soap” and “liquid soap causes allergy” have been present in the media. The press coverage was a result of a survey from the Danish Information Centre for Environment & Health showing that the majority of all liquid soaps on the market contain the allergen preservative MG (methyldibromo glutaronitrile). As Berendsen had already phased this preservative out of their soap products, they managed to use the negative publicity about soap products in a positive way. Hence, they could tell their clients that their soap products were safe and did not contain MG. As a large service company, Berendsen has a lot of suppliers – and unfortunately it is not possible to work closely together with all of them in developing new sustainable products. However, it is important for Berendsen to make sure that the suppliers act in compliance with the “code of conduct” of Berendsen. As a part of this Berendsen uses the internet-based tool Supplier-evaluation from FORCE Technology to evaluate and follow up on the performance of their suppliers. 2.1.4 Time monopolyProduct innovation is a way of staying ahead of competitors – also when the innovation is related to cleaner products. A certain segment of the market will require environmentally friendly and healthy products. Hence, if you at a certain time are the only one able to deliver, then until the competitors are able to deliver the same type of products you have a time monopoly for this segment of the market. 2.1.5 Comply with core valuesThe motivation of Berendsen is also more or less covered by the six core values on which the company builds.

Fodnoter * Berendsen Textile Service A/S shares brand with other companies in the Sophus Berendsen A/S group owned by Davis Service Group plc. Sophus Berendsen A/S operates with the Berendsen brand in Denmark, Sweden, Norway, Germany, the Netherlands, Poland and Estonia. 3 Overcoming barriers in environmental product development

During the pilot development projects and other development projects of Berendsen a lot of different barriers have been experienced. Common for most of them is that they can be broken down with persistency and patience.

3.1 Braking down the barriersThe barriers that had to be overcome were:

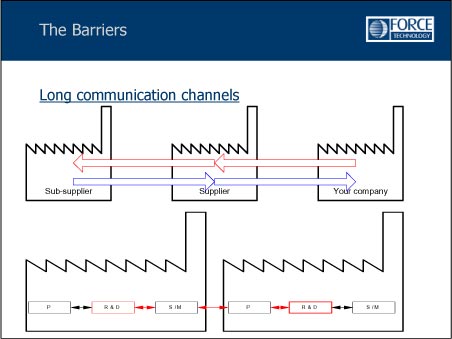

Each barrier is explained separately below, although they are often connected. 3.1.1 Different preferences on different marketsIn many countries the focus from the market is not on health and environmental issues. For example in many countries in southern Europe “clean” means that it smells good of perfume, whereas in Denmark perfume often is related to allergy. When you use a supplier that has its main markets in other countries or to other market segments than your own company then this barrier is often apparent. Combined with other barriers, it can be difficult to overcome this one – especially as a special formulation or design of a product leads to extra costs. For Berendsen the barrier was overcome with a combination of persistency and argumentation. Finally, the supplier was convinced that the demands seen on the Danish market today would be the demands of tomorrow on their own main markets. In other words - making the new cleaner formulation as a basis for their entire product range would secure the future of their products. 3.1.2 Long communication channelsBerendsen often uses wholesalers instead of buying directly at the producer. This means that the communication from Berendsen to the producer passes through the wholesaler giving a long communication channel, meaning that communication is often delayed and imprecise (blurred).

Figure 10. Information that passes through long communication channels is often delayed and misunderstood. When looking into more detail, the communication channels are often even longer. Communication between two companies often goes through a number of departments within the companies – making the risk of misunderstanding even higher – especially as there are differences in terminology between the different departments.

Figure 11. Even within the single company there can be long communication channels e.g. between different departments. If possible the barrier can be broken down by establishing direct communication channels between e.g. the R&D department of your company and the R&D department of the relevant sub-suppliers. However, if you try to do so, you will often experience another barrier - confidentiality. The supplier is not interested in you knowing too much so that you might be able to bypass the 1st tier supplier and buy directly at the manufacturer/2nd tier supplier. 3.1.3 Differences in language and terminologyWhen you cooperate with companies in other countries, the difference in language makes it more difficult to communicate and increases the risk of misunderstandings. A similar barrier is the difference in terminology between different professions/departments. The scientific staff in the research and development department uses other words than e.g. the marketing department. Of course, if they are used to working together, this barrier is of less importance. Again a solution can be establishment of direct communication channels between e.g. the two relevant R&D departments. There is no easy solution when it comes to difference in language, but of course if it is an important long lasting relationship it might be valuable to get some language training. 3.1.4 Physical distanceThe physical distance to your suppliers makes meetings more difficult, meaning that less personal communication channels like phone conferences and e-mail exchanges are often used as the only means of communication. As good personal relations are a driver for smooth cooperation, a barrier for personal relations like physical distance also becomes a barrier for cooperation on development of cleaner products in international product chains. This barrier is obviously not easily overcome, but as new technologies develop, the world becomes smaller. If the relations are intended to be important and long-lasting, investing in personal meetings to build up relations could pay off. 3.1.5 Lack of knowledgeWithout knowledge about the products that you are going to develop or reformulate, it is not possible to make the right decisions and to know if the improvements have real effects. For cosmetic products the problem is not as big as for chemicals. The legislation makes it impossible for the producers of cosmetics to keep the ingredients confidential – except for the constituents of perfumes. However, for chemical products it is possible for the manufacturers to have much more confidentiality, and the experience from Berendsen shows that when possible they keep the information confidential. Confidentiality about which sub-suppliers are used makes it impossible to communicate directly with the experts at the manufacturers concerning reformulation – and this creates the barrier described as long communication channels. For one of the products, Berendsen solved the lack of knowledge about the products and suppliers by initiating cooperation with a manufacturer in Asia. However, for this supplier, lack of knowledge was also a barrier as the supplier lacked knowledge about the chemical and cosmetic legislation in the European Union. To solve that problem, a lot of resources were used to support the Asian supplier with information about legislation. 3.1.6 Job changes/broken personal relationsWhen good personal relations have been established over a long time, it is a barrier if those relations are broken, e.g. due to a job change for one of the persons involved. However, if the relations are not good or if the person in the other end is not ready to meet your requirements or listen to your ideas, then a job change might break down the barrier. 3.1.7 Contractual barriersOne of the major barriers for Berendsen is that in some situations they are bound to long term contracts with suppliers. This means that Berendsen is forced to stick to that supplier – even if the supplier shows no interest in developing cleaner products. To break down the barrier, long term contracts should include something about meeting requirements of the market and being willing to develop new products. For Berendsen the long term contracts include a paragraph that makes it possible to change to a new supplier if the environmental properties of a product are not good enough, and the supplier is not willing to change. At Berendsen there is also good experience with long term contracts in relation to development of cleaner products. Long term cooperation with their main supplier of laundry detergents has improved the environmental properties of the chemicals and has further optimized the laundering processes. 3.1.8 Weak “power” relationsIn situations where Berendsen is the small player and their purchase volumes are of minor importance to the supplier, the motivation for the supplier to meet Berendsen’s requirements is limited. This is certainly a major barrier that can be difficult to overcome. However, experience shows that persistent pressure and the right argumentation can break down the barrier, but it takes time.

David can defeat Goliath One of the main suppliers of Berendsen for chemical and cosmetic products for their hygiene service is a very big company based in southern Europe. The purchases by Berendsen are insignificant in relation to the supplier’s total turnover on international markets. Some years ago one or two small companies started to ask Berendsen about the ingredients of their soaps. This initiated a process where a major supplier was critically asked by Berendsen about the ingredients and if they could be improved. After some pressure, to start they developed a special product for Berendsen not containing an undesired preservative. Berendsen kept the pressure to improve the products further and after a long time the supplier decided to reformulate their standard products to meet the demands of Berendsen. As a result of this, the products that are supplied today to all customers on the markets of the major supplier have a better environmental and health profile. Hence, the pressure initiated by a few small customers of Berendsen in the end had enormous positive environmental consequences. 3.1.9 Other barriers experiencedOther ‘single event’ barriers were experienced during the development projects. For example, after a new and cleaner hand cleaner was developed and put on the market, Berendsen wanted to change the dispenser meaning that the supplier had to change to another type of packaging. During this process the supplier started to deliver their standard product instead of the reformulated product without saying anything to Berendsen. When it was discovered, the error was corrected so that the cleaner product was put back on the market. 3.2 A little good adviceSumming up the experience shows that persistency and patience in relation to your suppliers is the most efficient way to overcome the hurdles. Patience does not mean that you just sit and wait, but that you do not give up when things get slow and complicated. 4 Product Development

|

| Product | Changes | Comments |

| Foam soap neutral | New preservative Removal of perfume (Still no colorant) |

In a life cycle perspective foam soaps in general are better for the environment than other liquid soaps. This is due to the fact that the amount of active soap ingredients used per hand wash is much lower. |

| Foam soap mild | New preservative Removal of colorant Change of perfume |

|

| Cream soap neutral | New preservative Removal of perfume (Still no colorant) |

|

| Cream soap mild | New preservative Removal of colorant Change of perfume |

4.2.2 Hand Cleaner

In the relatively early stages of the project, a new hand cleaner was developed and introduced to the market to replace the existing product. However, experience soon showed that in practice the new and cleaner product was not efficient enough to fulfil the quality demands of the customers. Therefore, a new formulation and more efficient formulation was made.

Table 2. New hand cleaner on the market during the project.

| Product | Changes | Comments |

| Hand Cleaner | New preservative Replacement of perfume Change of other functional ingredients |

4.2.3 Hand Lotion

Concerning the hand lotion it was very difficult to convince the supplier to make changes to the composition of the product. We did not have enough time. However, a change in the legislation meant that the supplier had to remove the undesired preservative from their product. A new and cleaner product has therefore been introduced to the market pushed by the EU legislation.

Table 3. New hand lotion put on the market during the project.

| Product | Changes | Comments |

| Hand Lotion | New preservative | Berendsen will work to improve this product further in the future. E.g. the undesired preservative MG was substituted by the manufacturer with parabens which Berendsen also considers a potential problem. |

4.2.4 Other Products

The above examples are directly related to the project, but in the same period Berendsen also developed other cleaner hygiene products and put them on the market. The following are some examples.

- Sanitizers

- Air-fresheners

- Hair & Body Shampoo

5 The Tools Used

To support an environmental product development process, a number of tools and useful preconditions are available. However, only a few of them have been relevant for Berendsen in specific product development. This chapter will present the tools and preconditions used by Berendsen and how they could be improved for the benefit of environmental product development.

5.1 Political push

In Denmark there has been an integrated product policy for more than a decade, where for instance it has been possible to fund development projects leading to a number of improvements for a large number of Danish companies who have been involved. Bang & Olufsen, Grundfos, Rockwool and Sophus Berendsen are just some examples. Today most of the Danish companies involved in Danish IPP projects are worldwide environmental frontrunners in their fields for the environmental profile of their products.

Life cycle thinking has become an integrated part of environmental work in many Danish companies.

Now the EU Integrated Product Policy is pushing and new legislation motivates companies to work with eco-innovation.

When it comes to the specific product development processes at Berendsen, the harmonised EU Cosmetics Directive has been important. The directive ensures a higher level of transparency concerning the products, making it easier to locate the problematic ingredients and initiate new development.

Compared to this, the legislation concerning chemical products does not ensure the same transparency. Hence, the suppliers can hide some potential problematic ingredients. New and more transparent legislation could push the development of “cleaner” chemical products, and hopefully the future chemicals legislation (REACH) will help in this respect.

5.2 Integration of life cycle thinking

There are many specific tools available that can be used for product development, but most important is not to sub-optimize but to include the whole life cycle of the product.

It is important to use tools and practices that can easily be integrated into the everyday life of a company.

Life cycle thinking can be integrated in many ways, but it is always a good starting point to have an idea of the environmental impacts of your products in a life cycle perspective.

Environmental procurement guidelines, criteria for environmental labels and other similar sources are an easy way to identify relevant issues concerning your products.

For Berendsen environmental labelling criteria have often been useful to benchmark their products and services on the environmental scale. For the specific products developed within the framework of this project, the chemical list connected to the eco-labelling criteria has supplied some easily accessible and useful information. However, sometimes the criteria do not relate the requirements to the functional unit of the product – for a soap this would mean to relate the environmental burden to a hand washing. Actually this means that even though it can be documented that the environmental burden of the Berendsen Neutral Foam Soap per hand washing is much less than a typical ecolabelled liquid soap, the foam soap cannot meet the criteria that is related to environmental burden per active ingredient.

A paradox is that the score to meet the ecolabelling criteria for Berendsen could be obtained e.g. by adding more preservative to the foam soap.

Therefore, on the basis of their experience Berendsen and FORCE Technology have supplied input to the future revisions of the environmental labelling criteria and procurement guidelines concerning soap products. The optimum would, of course, be to relate the criteria to the functional unit, but obviously this is very difficult. A suggestion is not to relate the environmental burdens to the sum of “so-called” active ingredients (everything but water) but instead to the sum of “functional-unit-related”, active ingredients and furthermore to make it possible to obtain the environmental label if you are able to document in another way that your product per functional unit has much lower environmental burdens than intended in the criteria set.

5.3 Specific tools used by Berendsen

The suppliers of Berendsen are essential in relation to developing cleaner products. To prepare their suppliers to meet the expectations Berendsen has a code of conduct and an environmental policy. The code of conduct and the environmental policy include environmental requirements on a broad scope as Berendsen has many types of suppliers.

To follow up on the many suppliers, Berendsen uses personal dialogue, but with many suppliers it is not possible to have a close dialogue. Instead Berendsen has invested in an internet-based tool to evaluate suppliers – Supplier-e-valuation® from FORCE Technology. Using such a tool eases the work to continuously motivate the suppliers to improve – not only the environmental properties, but all competitive parameters, as presented in the introduction and motivation chapter of the report.

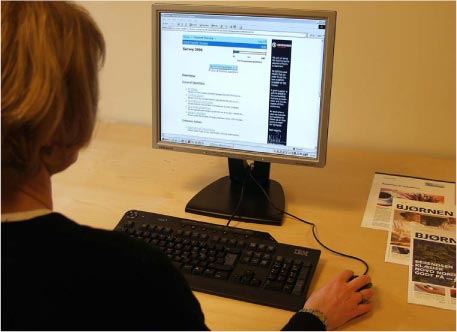

Figure 13. An internet-based tool for supplier evaluation is used to follow up on suppliers to continuously motivate them to improve and meet the expectations of Berendsen.

6 Project Communication

The main objective of the project was not to develop and market the cleaner products, but to share the experiences with other companies internationally as well as nationally.

The project and results have been presented at many different occasions and both FORCE Technology and Berendsen have used the opportunity, cooperation and good results to market their own services as a spin-off.

The communication channels and means used are:

- Presentation at conferences

- Workshops

- Articles for printing

- Web-based articles

Figure 14. Examples of some printed communication related to the project.

A summary of the communication is presented in the table below. Where relevant the communication has been presented in appendices.

Table 4. Communication at conferences and workshops.

| Title, Conference | Description | Language | Appendix |

| Barriers for Development of Cleaner Products in International Product Chains Conference: LCM 2005, Barcelona, Spain |

Platform presentation at the 2005 Life Cycle Management Conference. The focus of the presentation was on the barriers experienced and how they were overcome. | UK | A |

| Kan man udvikle renere produkter i samarbejde med sine internationale leverandører? Conference: Product oriented environmental work, Aarhus, Denmark |

Presentation of the project and motivation for Berendsen to involve in environmental product development. Conference arranged by the Danish Society of Engineers and LCA Center Denmark. | DK | B |

| Workshop: Sustainable Products | Workshop at FORCE Technology as part of the project to disseminate the experience obtained. Experience from Berendsen and IKEA as an introduction to more active group discussions about dilemmas in relation to sustainable products and their product chains. | DK | C |

| LCA in Denmark and Europe Conference: Current status and Future Tasks for LCA Research in the World, Tokyo, Japan |

Platform presentation at a Japanese LCA conference for industry. The project was presented as a small part of the presentation as an example of an IPP-related initiative from the Danish EPA. | UK/JP | |

| Planned Workshop: Life Cycle Management - Industry Workshop on Management & Stakeholder Engagement along the Life Cycle |

Berendsen has been invited to present their work at an international industry workshop arranged by the UNEP/SETAC Life Cycle Initiative. The conference is hosted by Unilever in Brussels during the first half of 2006. | UK |

Table 5. Communication in printed media.

| Title, Media | Description | Language | Appendix |

| Ren Livscyklus hos Berendsen Printed: Miljøhorisont |

An article written during the first half of the project presenting how Berendsen works in a life-cycle-oriented manner by integrating environmental work into relevant departments like purchases, production and sales/marketing. The article was the main story of the specific issue of the magazine. |

DK | D |

| Foam soap with clean conscience Printed: FORCE Technology Annual Report 2004 |

One of the customer case stories in the annual report of FORCE Technology, describing how Berendsen has benefited from the knowledge and services in relation to environmental product development. | DK/UK | |

| Fremtidssikrede produkter fastholder Berendsens position som markedsleder Printed: Fra viden til værdi |

A promotional customer case story in the FORCE newspaper for the industrial fair in Herning 2005. | DK | |

| Sæbe er vel sæbe? Printed: Bjørnen, Nov. 2004 |

A promotional article in the Berendsen customer magazine telling that Berendsen seriously works to develop cleaner products. Focus on the new foam soap. | DK | |

| Products of the future secure Berendsen’s position as market leader in Denmark For printing. |

An article intended for an international textile service to inspire other companies to work with development of cleaner products. | UK | E |

| Rent miljø er en konkurrencefordel For printing. |

Article written in relation to the project by a journalist from the Danish EPA. Focus is on the competitive advantages you can achieve if you develop cleaner products. The article is intended to inspire other companies to look at their own products to make some changes. | DK | F |

| Rent miljø handler også om sæbe For printing. |

Article written in relation to the project by a journalist from the Danish EPA. | DK | G |

Table 6. Communication in electronic media.

| Title, Website | Description | Language | Appendix |

| Berendsen Textil Service A/S Web: LCA Center Denmark |

Same as “Ren Livscyklus hos Berendsen” in Miljøhorisont – just placed as an example of a company working with life cycle thinking. LCA Center has many further inspiring examples of other companies and organisations working with life cycle thinking with success. | DK | |

| Ren Livscyklus hos Berendsen Web: Horisontnet |

Same as in Miljøhorisont | DK | |

| Berendsen skumsæbe er i særklasse Web: Berendsen Textil Service |

Promotional article at the website of Berendsen showing that Berendsen is a frontrunner concerning cleaner products. | DK | |

| Web: FORCE Technology | Same as in the annual report | UK/DK |

Appendix A

Presentation at LCM 2005

Appendix B

Conference: Product Oriented Environmental Work [Danish]

Appendix C

Workshop: ”Experience with development of sustainable products in co-operation with suppliers”

On 10 November 2005 FORCE Technology, Berendsen Textil Service A/S, EcoForum and LCA Center arranged an “after-work workshop” in co-operation with the Danish Environmental Protection Agency.

Presentations

Initially, Christian Steen, Berendsen Textil Service A/S, and Jeppe Frydendal, FORCE Technology/LCA Center, made a presentation on barriers for development of cleaner products in international product chains with basis in cases and experience of Berendsen Textil Service A/S.

[Presentations are in Danish]

Jonas Engberg, IKEA, followed with a presentation of IKEA’s work to overcome barriers for sustainable development in their supplier chains.

Active group discussions

Then there was a planned group work with starting point in a number of dilemmas connected to handling of divergent demands from customer and problems in relation to implementation of Code of Conduct respectively.

Handling of the customers’ demands

As a supplier you can experience that your customers have different opinions and priorities when it comes to demands to sustainability. The specific demands of your customers can vary both in content and form as well as demands to documentation. Question is how a company can relate to the many and often divergent demands and how the company in the best way can relate to individual cases which suddenly appear. On basis of the discussions in two groups several different input were presented.

Customer demands represent a potential

It was stated that basically customer demands should be seen as a potential and a possibility for development and innovation. Demanding customers are not only “troublesome” but can contribute to open new perspectives and possibilities and to develop the supplier.

It is important with own approach and effort

Both groups emphasized that it is important to define your own approach. To identify where the possibilities of the company are as well as where and how the company gets “most environment for the money”.

Systematic approach to handling of the customers’ demands

Demands from many different customers make it necessary to systematize and analyse which inquiries requiring action, which can be put on “stand-by” and which can be disregarded. It was emphasized that a large part of the customers’ demands often will be similar so that it will be possible for the company to “adapt” to the majority – maybe 80% - of the demands. Being prepared as a company is among other things to be able to fulfil the approx. 80%. The company can then consider if they want and can live up to the last 20%. In the communication with the customer you can – if possible – make clear that you fulfill the majority of the demands and that the last 20% then has to be reflected in the price. It was also stated that the company can reach a competitive advantage by fulfilling the last 20%.

It was also suggested that the company could establish a system/a data bank for collection of feedback from the customers. Such a knowledge bank will be a substantial resource for the supplier who will also be able to use the data among other things as input to product development.

The demands do not only come before the contract

A participant stated that in some cases demands from customers come after signing of the contract and realization of the agreement. This is problematic as the demands are not included as a part of the contract negotiations. It may still be a case of demands (and not only extra wishes) which you as a company more or less might be forced to fulfil.

Preparedness for handling of suddenly appeared incidents

The groups emphasized that as a company it is important to have a preparedness to be able to counter cases that suddenly appear. A participant stressed that at many points it could be compared with the political system where cases often appear and politicians must have an answer ready. In the same connection it was also emphasized that it is important to know your own company so you are fully prepared to handle cases.

It was also emphasized that the company can “go on hold” if it is not directly involved or deny if an answer is demanded. However, the cases will often re-appear.

Problems in relation to implementation of Code of Conduct

If you as a customer want to make sure that the suppliers keep certain fundamental demands a solution could be preparation of a Code of Conduct. With the implementation of the Code the problems occur if the suppliers fail to meet the Code. Are they to be thrown out (“comply or goodbye”)? Or should the company be given some help with guidance and education? How can it be assured that the suppliers keep the Code?

Necessary with a varied approach

Both groups agreed that it is absolutely necessary with a varied approach. A black/white – “comply or goodbye” – does not work. It was emphasized that implementation of sustainability is a process and that changes are not generated from one day to another. In this connection it was also stressed that it is important to create visible results – related to process as well as product.

One participant commented that in some cases it might actually be necessary with a more simply approach (“comply or goodbye”). It depends on how vulnerable the company is. For instance, Disney cannot accept that their toys for children are manufactured by children living under conditions similar to slave work.

Scope and power relationship in the chain

Relative strength in the value chain is a critical factor for the customer as well as the scope and the possibilities of the supplier to make demands. As Jonas Engberg stated in his presentation IKEA has a size which makes it possible for them to make demands to the suppliers. In other cases the balance of power might be another (for instance a leading multinational supplier and a small customer).

Minimum requirements combined with development

Even if the customer necessarily may have a varied approach with standards and development at the supplier there is also a need for some minimum requirements. Here it is necessary to look at local conditions. Development of suppliers contributes to “raise the level” and gives the supplier some advantages as he becomes “better” and thus also more attractive for other customers.

Tools and methods

Whether to use questionnaires or dialogue depends on the supplier portfolio and the product. It is necessary to distinguish if you have many or a few suppliers and if it is peripheral or central products (there is a difference between buying helicopters and bulk goods).

It was stated that audits are an important tool to ensure that the suppliers meet the Code and agreements about continuous development. Audits may only be carried out on basis of clear instructions and conditions and can with advantage be completed by well-educated auditors who have a local knowledge, know the culture etc.

Some of the present companies could inform that LCA was not a criterion in the selection of suppliers but the life cycle thinking is included for instance through the ecolabelling.

Establishment of a bench marking system (such as EPD) was pointed out as a possibility because it gives measurable results in the performance part among suppliers in the value chain.

Appendix D

Rent miljø er en konkurrencefordel

Miljøhensyn er blevet en konkurrencefordel. Det har ansporet Berendsen Textil Service A/S til at udvikle miljøvenlige produkter. Under Miljøstyrelsens ’Program for renere produkter’ har Berendsen Textil Service A/S i samarbejde med FORCE Technology udviklet en miljøvenlig skumsæbe. Det er blevet en succeshistorie for Berendsen, brugerne af sæben og miljøet.

Af Thomas Ambrosius, journalist

REN LOGIK

På baggrund af en såkaldt livscyklusvurdering af sæbe er det lykkes Berendsen Textil Service A/S i samarbejde med FORCE Technology at udvikle en skumsæbe, som er både miljøvenlig og uden allergifremkaldende og hormonforstyrrende indholdsstoffer

Berendsen motivation for at kaste sig over projektet er flersidet. For det første ser Berendsen en konkurrencefordel i at udvikle produkter, der er mere miljøvenlige end konkurrenternes – ganske enkelt, fordi miljø er blevet et salgsparameter. For det andet efterspørger flere kunder miljøvenlige produkter. Endelig undgår Berendsen ifølge produktchef Christian Steen at blive overhalet inden om af ny miljølovgivning eller historier i pressen, som man senest har set med Colgate og det bakteriedræbende stof triclosan, der er mistænkt for at gøre bakterier multiresistente.

”Miljøet er en af de parametre, hvor man kan adskille sig fra konkurrenterne. Man kan sige, at vi med vores nye skumsæbe har opnået et tidsmonopol, indtil konkurrenterne har fremstillet en sæbe, som er lige så god og miljøvenlig som vores,” siger Christian Steen.

Krav til leverandøren

Berendsen fremstiller ikke skumsæben selv. Derfor har virksomheden stillet helt specifikke krav til leverandøren. Det har været en vanskelig proces, forklarer Christian Steen. Men med gode argumenter lykkedes det Berendsen at få leverandøren i Sydeuropa til omstille produktionen af sæbe til den miljøvenlige skumsæbe.

”Den største barriere var at overbevise vores leverandør om at fremstille en sæbe uden parfume, for i Sydeuropa betyder ’rent’, at det skal dufte godt. Men vi fik dem overbevist om, at det var en fordel for dem at fremstille en neutral grundsæbe. Den kan de så tilsætte parfume til de kunder, som vil have en sæbe, der dufter ’rent’, mens vi køber den neutrale grundsæbe. Et andet argument var, at den efterspørgsel, der er på miljøvenlig sæbe i Danmark og Skandinavien i dag, også vil nå til Sydeuropa. På sigt vil vores leverandør altså også få en konkurrencefordel på det sydeuropæiske marked ved allerede at omstille produktionen nu. Derfor gik de med til at omstille produktion, selv om Berendsen i denne sammenhæng er en lille aftager af virksomhedens produkter,” siger Christian Steen.

Miljøgevinster

Hos FORCE Technology er det civilingeniør og leder af LCA Center Jeppe Frydendal, der har ydet Berendsen konsulentbistand. Han forklarer, at livscyklusvurderinger (LCA) betyder, at man får et mål for et produkts samlede miljøbelastning fra udvinding af råstoffer over fabrikation og brug til bortskaffelse af produktet. Man beregner simpelthen et produkts samlede miljøbelastning fra vugge til grav. Berendsens skumsæbe belaster for eksempel miljøet mindre end flydende creme-håndsæber. Ofte giver livscyklusvurderinger og livscyklustankegangen også økonomiske fordele, f.eks. når de fremhæver, hvor man kan optimere processerne og spare penge på f.eks. ressourcer eller energi.

”Den skumsæbe, vi har udviklet, er nem at påføre og vaskes lettere af huden end flydende sæbe. Man skal heller ikke bruge vand på at opskumme sæben, og så strækker den længere end flydende sæbe. Det betyder alt i alt, at man reducerer vandforbruget ganske betydeligt, når man vasker hænder” siger Jeppe Frydendal.

Klar ved håndvasken

Hvor mange gange om dagen vasker dine medarbejdere hænder i løbet af en arbejdsdag? Otte gange? Hvor mange medarbejdere har virksomheden? 30, eller måske 200? For den lille virksomhed bliver det 240 håndvaske om dagen eller 48.000 på et år med 200 arbejdsdage. For virksomheden med 200 medarbejdere bliver det til ikke mindre end 320.000 håndvaske på et år.

Det er meget sæbe og endnu mere vand – ofte varmt vand.

Med sådan et regnestykke i baghovedet bliver det pludselig ikke helt ligegyldigt, hvilken håndsæbe medarbejderne bruger. Hverken for den enkelte medarbejders sundhed, virksomhedens økonomi eller miljøet.

Hvis den enkelte medarbejder sparer én liter vand pr. håndvask, vil den store virksomhed med 200 ansatte altså spare 320.000 liter vand om året - og miljøet for ligeså meget spildevand. Dertil kommer, at skumsæben kun indeholder biologisk nedbrydelige stoffer, som renseanlæggene ikke har problemer med og at virksomheden også sparer energi til at opvarme de 320.000 liter vand.

Allergi

Allergi er et stigende problem i Danmark. Derfor har også sundhed spillet en afgørende rolle i udviklingen af Berendsens skumsæbe, som er uden parfume og farvestoffer. Mange flydende håndsæber indeholder konserveringsmidlerne MG (methyldibromoglutaronitrile), som ifølge Videnscenter for Allergi er allergifremkaldende, samt parabener, som er stærkt mistænkt for at være hormonforstyrrende. Dem har Berendsen fået erstattet med god gammeldags atamon, som de fleste kender fra syltning.

Berendsen har under Miljøstyrelsens ’Program for renere produkter’ også udviklet en miljøvenlig håndrens og en sanitizer (toiletrens) uden hormonforstyrrende stoffer. Men udviklingen stopper ikke der. Der er flere nye produkter på vej. Projektet har i det hele taget ansporet Berendsen til at udvikle miljøvenlige produkter, siger produktchef Christian Steen.

Fakta

- Livscyklusvurderinger, LCA, bruges til at beregne miljøbelastningen af et givet produkt i dets levetid fra råstofudvinding til bortskaffelse.

- LCA Center er et dansk videncenter for livscyklusvurderinger og livscyklustankegangen, der skal servicere virksomheder samt offentlige og private institutioner. Centeret er delvist finansieret af Miljøstyrelsen. Centeret drives af IPU, COWI og FORCE Technology.

- Adresse: LCA Center, FORCE Technology, Hjortekærsvej 99, 2800 Kgs. Lyngby.

LCA Centers formål er:

- At hjælpe dansk erhvervsliv og andre, der har behov for miljøvurdering af produkter og tjenesteydelser i et livscyklusperspektiv.

- At sikre at indsatsen på dette område i Danmark foregår på et solidt og videnskabeligt funderet grundlag.

- At fremme produktorienteret miljøarbejde, herunder brugen af livscyklusvurderinger og andre miljøledelsesværktøjer.

- At fastholde det gode samarbejde mellem alle væsentlige aktører på LCA-området i Danmark, der har præget udviklingen indtil nu.

- Læs meget mere om miljø og livscyklusanalyser på: www.lca-center.dk.

Gode råd om sæbe

- Undgå miljøbelastende og hormonforstyrrende stoffer.

- Undgå stoffer, som ikke er let biologisk nedbrydelige, fx centrimonium chlorid, 2-bromo-2nitropropane-1, 3-diol, og quaternium-15.

- Undgå hormonforstyrrende stoffer som konserveringsmidlet buthylparaben.

- Undgå EDTA – EDTA er ikke i sig selv miljøbelastende, men kan frigøre miljø- og sundhedsskadelige tungmetaller.

- Undgå det antibakterielle stof triclosan, som Miljøstyrelsen vurderer, udgør en belastning for miljøet, og som mistænkes for at medvirke til dannelsen af multiresistente bakterier, der vil være vanskelige at bekæmpe med antibiotika.

- Undgå overdosering. Vask hænderne grundigt, men med så lidt sæbe som muligt

Kilde: Råd om Miljø og Forbrug, Informationscenteret for Miljø og Sundhed.

Billedtekst: Under Miljøstyrelsens ’Program for renere produkter’ er det lykkedes Berendsen Textil Service at udvikle en ny skumsæbe. Det er en succeshistorie for Berendsen, miljøet og brugerne af sæben, som undgår allergifremkaldende og hormonforstyrrende stoffer.

Appendix E

Rent miljø handler også om sæbe

Miljøhensyn er blevet en konkurrencefordel. Det har ansporet Berendsen Textil Service A/S til at udvikle miljøvenlige produkter. Under Miljøstyrelsens ’Program for renere produkter’ har Berendsen Textil Service A/S i samarbejde med FORCE Technology udviklet en miljø- og allergivenlig skumsæbe. Det er blevet en succeshistorie for Berendsen, brugerne af sæben og miljøet.

Af Thomas Ambrosius

MILJØ

Hvor mange gange om dagen vasker dine medarbejdere hænder i løbet af en arbejdsdag? Otte gange? Hvor mange medarbejdere har virksomheden? 30, eller måske 200? For den lille virksomhed bliver det 240 håndvaske om dagen eller 48.000 på et år med 200 arbejdsdage. For virksomheden med 200 medarbejdere bliver det til ikke mindre end 320.000 håndvaske på et år.

Det er meget sæbe og endnu mere vand – ofte varmt vand.

Med sådan et regnestykke i baghovedet bliver det pludselig ikke helt ligegyldigt, hvilken håndsæbe medarbejderne bruger. Hverken for den enkelte medarbejders sundhed, virksomhedens økonomi eller miljøet.

Fra vugge til grav

På baggrund af en såkaldt livscyklusvurdering af sæbe er det lykkes Berendsen Textil Service A/S i samarbejde med Force Technology at udvikle en skumsæbe, som både er miljøvenlig og uden allergifremkaldende og hormonforstyrrende indholdsstoffer

Hos FORCE Technology er det civilingeniør og leder af LCA Center Jeppe Frydendal, der har ydet Berendsen konsulentbistand. Han forklarer, at livscyklusvurderinger (LCA) betyder, at man får et mål for et produkts samlede miljøbelastning fra udvinding af råstoffer over fabrikation og brug til bortskaffelse af produktet. Man beregner simpelthen et produkts samlede miljøbelastning fra vugge til grav. Berendsens skumsæbe belaster for eksempel miljøet mindre end flydende creme-håndsæber. Med livscyklusvurderinger finder man ofte en række forbedringspotentialer, der ikke kun er godt for miljøet, men også kan spare virksomheden for udgifter til energi og råvarer, eller man finder måske en måde at forbedre produktet sundhedsmæssigt fra vugge til grav.

”Den skumsæbe, vi har udviklet, er nem at påføre og vaskes lettere af huden end flydende sæbe. Man skal heller ikke bruge vand på at opskumme sæben, og så strækker den længere end flydende sæbe. Det betyder alt i alt, at man reducerer vandforbruget ganske betydeligt, når man vasker hænder” siger Jeppe Frydendal.

Hvis den enkelte medarbejder sparer én liter vand pr. håndvask, vil den store virksomhed med 200 ansatte altså spare 320.000 liter vand om året - og miljøet for ligeså meget spildevand. Dertil kommer, at skumsæben kun indeholder biologisk nedbrydelige stoffer, som rensningsanlæggene ikke har problemer med.

Allergi

Allergi er et stigende problem i Danmark. Derfor har også sundhed spillet en afgørende rolle i udviklingen af Berendsens skumsæbe, som er uden parfume og farvestoffer. Mange cremehåndsæber indeholder konserveringsmidlerne MG (methyldibromoglutaronitrile), som ifølge Videnscenter for Allergi er allergifremkaldende, samt parabener, som er stærkt mistænkt for at være hormonforstyrrende. Dem har Berendsen fået erstattet med god gammeldags atamon, som de fleste kender fra syltning.

Krav til leverandøren

Berendsen fremstiller ikke skumsæben selv. Derfor har virksomheden stillet helt specifikke krav til leverandøren. Det har været en vanskelig proces, forklarer produktchef Christian Steen, Berendsen. Men med gode argumenter lykkedes det Berendsen at få leverandøren i Sydeuropa til omstille produktionen af sæbe til den miljøvenlige skumsæbe.

”Den største barriere var at overbevise vores leverandør om at fremstille en sæbe uden parfume, for i Sydeuropa betyder ’rent’, at det skal dufte godt. Men vi fik dem overbevist om, at det var en fordel for dem at fremstille en neutral grundsæbe. Den kan de så tilsætte parfume til de kunder, som vil have en sæbe, der dufter ’rent’, mens vi køber den neutrale grundsæbe. Et andet argument var, at den efterspørgsel, der er på miljøvenlig sæbe i Danmark og Skandinavien i dag, også vil nå til Sydeuropa. På sigt vil vores leverandør altså også få en konkurrencefordel på det sydeuropæiske marked ved allerede at omstille produktionen nu. Derfor gik de med til at omstille produktion, selv om Berendsen i denne sammenhæng er en lille aftager af virksomhedens produkter,” siger Christian Steen.

På forkant med udviklingen

Berendsen egen motivation for at kaste sig over projektet er flersidet. For det første efterspurgte flere kunder miljøvenlig produkter. For det andet ser Berendsen en konkurrencefordel i at udvikle produkter, der er mere miljøvenlige end konkurrenternes – ganske enkelt, fordi miljø er blevet et salgsparameter. Endelig undgår Berendsen ifølge Christian Steen at blive overhalet inden om af ny miljølovgivning eller historier i pressen, som man senest har set med Colgate og det bakteriedræbende stof triclosan, der mistænkes for at gøre bakterier multiresistente.

”Miljøet er en af de parametre, hvor man kan adskille sig fra konkurrenterne. Man kan sige, at vi med vores nye skumsæbe har opnået et tidsmonopol, indtil konkurrenterne har fremstillet en sæbe, som er lige så god og miljøvenlig som vores,” siger Christian Steen.

Berendsen har under ’Program for renere produkter’ også udviklet en miljøvenlig håndrens og en sanitizer (toiletrens) uden hormonforstyrrende stoffer. Men udviklingen stopper ikke der. Flere nye produkter er på vej. Projektet har i det hele taget ansporet Berendsen til at udvikle miljøvenlige produkter, siger Christian Steen.

Fakta

- Livscyklusvurderinger, LCA, bruges til at beregne miljøbelastningen af et givet produkt i dets levetid fra råstofudvinding til bortskaffelse.

- LCA Center er et dansk videncenter for livscyklusvurderinger og livscyklustankegangen, der skal servicere virksomheder samt offentlige og private institutioner. Centeret er delvist finansieret af Miljøstyrelsen. Centeret drives af IPU, COWI og FORCE Technology.

- Adresse: LCA Center, FORCE Technology, Hjortekærsvej 99, 2800 Kgs. Lyngby

LCA Center formål er:

- At hjælpe dansk erhvervsliv og andre, der har behov for miljøvurdering af produkter og tjenesteydelser i et livscyklusperspektiv.

- At sikre at indsatsen på dette område i Danmark foregår på et solidt og videnskabeligt funderet grundlag.

- At fremme produktorienteret miljøarbejde, herunder brugen af livscyklusvurderinger og andre miljøledelsesværktøjer.

- At fastholde det gode samarbejde mellem alle væsentlige aktører på LCA-området i Danmark, der har præget udviklingen indtil nu.

- Læs meget mere om miljø og livscyklusanalyser på: www.lca-center.dk.

Gode råd om sæbe

- Undgå miljøbelastende og hormonforstyrrende stoffer.

- Undgå stoffer, som ikke er let biologisk nedbrydelige, fx centrimonium chlorid, 2-bromo-2nitropropane-1, 3-diol, og quaternium-15.

- Undgå hormonforstyrrende stoffer som konserveringsmidlet buthylparaben.

- Undgå EDTA – EDTA er ikke i sig selv miljøbelastende, men kan frigøre miljø- og sundhedsskadelige tungmetaller.

- Undgå det antibakterielle stof triclosan, som Miljøstyrelsen vurderer, udgør en belastning for miljøet, og som mistænkes for at medvirke til dannelsen af multiresistente bakterier, som vil være vanskelige at bekæmpe med antibiotika.

- Undgå overdosering. Vask hænderne grundigt, men med så lidt sæbe som muligt

Kilde: Råd om Miljø og Forbrug, Informationscenteret for Miljø og Sundhed.

Billedtekst: Under Miljøstyrelsens ’Program for renere produkter’ er det lykkedes Berendsen Textil Service at udvikle en ny skumsæbe. Det er en succeshistorie for Berendsen, miljøet og brugerne af sæben, som undgår allergifremkaldende og hormonforstyrrende stoffer.

Appendix F

Products of the future secure Berendsen’s position as market leader in Denmark

In cooperation with FORCE Technology and their suppliers, Berendsen has managed to develop a new range of hygiene products for their facility service that are more environmentally friendly and safer to use. The customers of Berendsen are satisfied with the new products – and it cements Berendsen’s position as a market leader.

At Berendsen Textile Service A/S they know the demands of their customers in advance. When the alarm in the media was raised that many liquid soaps could cause allergy because of the preservative MG, the substance had already been phased out of Berendsen’s products. Hence, Berendsen was able to use the media coverage proactive in their marketing of their hygiene products.

Competitive advantages

Environment is not a primary sales argument, as customers are often more focused on:

- Price

- Quality

- Security of supply

- Service level

- Etc.

However, as Christian Steen from Berendsen states: “Environment is one of the parameters where you can differentiate from your competitors. On environmentally concerned markets like in the Nordic Countries this often shows to be the balance between selling and not selling to a customer”.

The value chain or life cycle approach is important when developing new products as all sales parameters are influenced by the whole value chain. Therefore, optimizing the value chain of your products and services will lead to a higher competitiveness.

Figure 15. Cooperation in the value chain to improve the competitive parameters for the final product/service yields a better competitiveness. This is a motivation to cooperate on optimizing the value chain as a whole.

Development of cleaner products

The development projects at Berendsen have shown to be a success. During the last few years Berendsen has put new soaps, lotions, sanitizers, air fresheners etc. on the market with an improved environmental and safety profile. However, some barriers had to be broken down to reach the goals – and in some situations alternative suppliers had to be chosen.

One of the important barriers for Berendsen in Denmark is that they are operating on an environmentally demanding market whereas their suppliers e.g. in southern Europe do not meet the same demands from their main markets. Popularly speaking, clean in southern Europe means that it smells good of perfume whereas in Denmark perfumes are often undesired because of the ability to cause skin irritation and allergy. For a relatively small player like Berendsen (compared to some big suppliers) it can be difficult to influence the suppliers when the preferences on the markets are so different.

Overcoming barriers

“The best advice that can be given is to be patient and persistent in the dialogue with your suppliers”, says Jeppe Frydendal from FORCE Technology. For Berendsen one of the successes came when their major supplier understood that complying with the demands of the Danish market was to be proactively complying with the demands of their own main markets in southern Europe.

Future outlook

For Berendsen developing a new product and putting it on the market does not mean that the job is done. They are always looking for further improvements based on tendencies on the market as well as the newest scientific knowledge as is expected from a market leader.

Further information

For further information contact Mr. Jeppe Frydendal, FORCE Technology

jpf@force.dk

+45 72 15 77 00

Version 1.0 March 2006, © Danish Environmental Protection Agency