Green Technology Foresight about environmentally friendly products and materials

5 Nanotechnology development in Denmark – environmental opportunities and risks

- 5.1 Introduction

- 5.2 Nanotechnology - definitions and dynamics

- 5.3 Nanotechnology - international findings on environmental risks and opportunities

- 5.4 Danish findings on path creation in nanotechnology

- 5.5 Danish Nano Eco-innovation potentials

- 5.6 Environmental assessment - system expansion or system substitution

- 5.7 Conclusion

Maj Munch Andersen with contribution from Stig Irving Olsen and Birgitte Rasmussen[9]

5.1 Introduction

Research and debate on environmental issues related to nanotechnology mainly focus on risk aspects. There are in recent years rising attentions to ethical, social and environmental concerns related to nanotechnology, making it likely that risk and ethical issues are going to be as important to nanotechnology as it has been to biotechnology. New regulations are considered and a serious of research projects are either coming out these years or are under way around the globe, noticeable the recent report from the Royal Academy (2004) and EC SANCO (2004). These reports have presented some of the so far most comprehensive research into the toxicity of nanotechnology, showing serious concerns related to nano particles.

Nano eco-opportunities are very often referred to in the literature discussing the scope of nanotechnology (but not necessary in the risk or technology assessment literature), often with very high expectations of considerable environmental advantages (Jacobstein, 2001,Wood et al. 2003, Nanoforum 2004, The Royal Society, 2003, 2004, European Commission 2004). These statements are, however, often of a very general and superficial character and more in depth studies are needed both on the scope and the dynamics involved.

The intention of this study is two fold: It seeks to investigate the dynamics of early path creation within nanotechnology; more specifically how environmental issues form a part of the search processes of the various actors in the emerging nano technological field in Denmark. This is in other words a qualitative analysis of the drivers, expectations and learning modes of the Danish nano innovation system.

It aims to identify (map) the eco-opportunities and -risks related to nanotechnology as perceived by the Danish nano researchers. It implies in other words a broad scanning which naturally limits the depth of the analysis of specific scientific and technology developments as well as their environmental implications. On the other hand it offers an opportunity to give a comprehensive picture of where the main innovation activities and search processes in the Danish nano community seems to be heading and by whom (which researchers and companies are involved). The mapping, then, provides the broader context in relation to which the individual innovations should be seen.

The mapping also serves as a tool for networking in the nano community during as well as –hopefully- after the foresight project, as such a mapping of research activities in the Danish nano community has not been carried out before.

This analysis does not seek to discuss how green nanotechnology is or where the best eco-opportunities are. This task makes little sense owing to the very early stage of development and the highly diverse nature of nanotechnology. Since it is hardly yet a technology the uncertainties as to the future development are considerable. Rather, the analysis here focuses on analysing the early path creation and identifying the expectations on eco-opportunities related to nano science. By analysing path creation, the evolving lock-in into technological paths is highlighted. Hereby the directions of the search processes going on are sought captured. These indicate long term perspectives on the directions nanotechnology development may take in Denmark.

An innovation economic perspective is applied in the analysis of the nanotechnology development. Very few such studies at the microlevel of nanotechnology development have been made so far, so there is little analysis to build on or relate to, in Denmark or elsewhere. The analysis builds mainly on an interview based qualitative analysis combined with a broader mail based mapping undertaking within the Danish nano community.

The analysis looks into:

- What is nanotechnology?

- What do international findings say on environmental opportunities and risks of nanotechnology?

The path creation processes within nanotechnology in Denmark. Focus is on how environmental issues enter into the strategies and search processes of Danish nano researchers and related industry. The identification of nanotechnology eco-opportunities more generally and through case studies.

5.2 Nanotechnology – definitions and dynamics

This section seeks to present and characterize nanotechnology. A few comments are made on the innovation dynamics of nanotechnology and how innovation in nanotechnology is analysed in this report.

5.2.1 What is nanotechnology?

Nanotechnology is an emerging general purpose technology. It is expected to have widespread impacts on society by replacing or influencing existing materials and technologies. The scope of nanotechnology is as yet very uncertain but same have anticipations that it may form the basis of a new industrial revolution, i.e. disrupt and transform the existing technology platforms in line with the steam engine, electrification and computer technology.

Nanotechnology is commonly understood as dealing with very small things. A nanometer (nm) is indeed small, one thousand millionth of a metre. The significance of the nano scale is, however, not only that things are small, but that materials obtain new properties here. This is mainly due to two reasons. First, nanomaterials have a relatively larger surface area. This can make materials more chemically reactive and affect their strength and electrical properties. Second, quantum effects can begin to dominate the behaviour particularly at the lower end of the nano scale, which affects the optical, electrical and magnetic behaviour of materials.

Materials can be produced that are nano scale in one dimension, such as very thin surface coatings. Or two dimensions such as nanowires and nano tubes or in three dimensions such as various kinds of nano particles.

Nanotechnology is the design, characterisation, production and application of structures, devices and systems that entails controlling the shape and size at the nanometre scale.

The size range of nanotechnology is often delimited to 100 nm down to the molecular level (approximately 0.2 nm) because this is where materials have significant different properties. But it is disputed how strict to delimited nanotechnology. The need to integrate with other length scales to obtain wider technology development is emphasized.

Nanoscience is the study of phenomena of materials at atomic, molecular and macromolecular scales, where properties differ significantly frm those at a larger scale.

Since the 1990’s the nanotechnology term has shot into the limelight. Research into and even technologies based on nano scale structures is, however nothing new.

What has led to a breakthrough and hence the rise of nanotechnology as a phenomenon is the development of new sophisticated tools to observe, measure and manipulate processes at the nanoscale level. These tools have emerged within the last 25 years. Noticable tools such as STM (scanning tunnelling microscope) from 1982, AFM (atomic force microscope) from 1986 and TEM (transmission electron microscopy), but there are nowadays a range of other tools. Before these tools research and development at the nano scale was experimental trial and error.

The new tools are leading to a greater understanding of and control of processes at the nanoscale and gradually the ability to design materials with specific properties. “Nanometrology”, research into the ability to measure and characterise materials at the nano scale, forms the basis for nanotechnology. Research using and manufacture based on these instruments is then what constitutes the nanotechnological field.

Conceptually the rise of nanotechnology was laid out by the physicist Feynman in his lecture from 1959 “There is plenty of room at the bottom”, foreseeing the possibility to examine and control matter at the nano scale. The term nanotechnology was first used by the Japanese researcher Taniguchi in 1974 referring to the ability to engineer materials at the nanometre scale. The driver was minituarisation in the electronics industry. Already in the 1970s nanostructures were created as small as 40-70 nm using electron beam lithography.

To day much of the research and development is still at the experimental stage (Lux Research 2004, Cientifica 2003).The commercialization of nanotechnology depends on laboratory experiments being turned into large scale, reliable and economic methods. Techniques and specific instrumentation for fabrication, control and measurement at the nanometer scale are under development but face major challenges. Concerning production methods two main routes can be distinguished:

- Top-down approach: Reduction in structure sizes of microscopic elements to the nanometer scale by applying specific machining and etching techniques (e.g. lithography, ultraprecise surface figuring)

- Bottom-up approach: Controlled assembly of atomic and molecular aggregates into larger systems (e.g. clusters, organic lattices, supramolecular structures and synthesised macromolecules).

Current commercial nanoproducts are based on top-down approaches while bottom-up approaches are still more, in some cases very, experimental. It is here, though, there are the big expectations of achieving efficient large scale fast production of nanomaterials which may form the basis of an industrial revolution. As yet though bottom-up manufacturing methods have not really materialized meaning that the uncertainty as to the connectivity and future paths of the nano technological field is highly uncertain. In the latter years we are seeing a beginning synthesis of the top-down and bottom-up approaches, a significant stage in the materialization of nanotechnology. Figures 5.1 and 5.2 illustrate some main features of nano production techniques are illustrated.

Figure 5.1 Bottom-up and top-down nano manufacturing techniques.

Source: The Royal Society, 2004 p.25

Figure 5.2 Generic processes in the production of nano particles.

Source: The Royal Society, 2004 p.25

In many ways nanotechnology is not á technology yet, and perhaps it never will be. It may more be characterized as a a platform technology rather than one distinctive technology entailing a wide range of very different fabrication techniques, as the figure illustrates. Indeed many refer consequently to nano technologies in the plural.

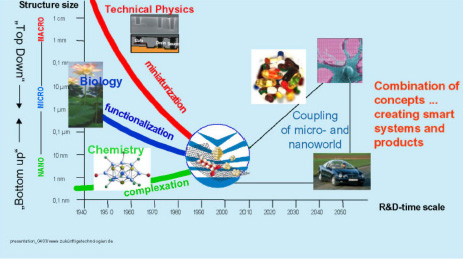

Adding to the confusion as to what constitutes nanotechnology is the multidisciplinarity of the field. Nanotechnology is based on a convergence during the latest century of basic disciplines such as technical physics, molecular biology and chemistry all trying to operate and manipulate at a nanoscale level, see figure 5.3. This common scale of operation and manipulation has opened up for a multidisciplinarity and combination of scientific paradigms leading to new research areas and possibilities for new technology development.

Figure5.3 Multidisciplinarity and combination of paradigms (Luther, 2004a).

The nanotechnological conglomerate may be divided into the following subsections: nanostructured materials, nanoelectronics, nanophotonics, nanobiotechnology and nanoanalytics, which illustrate the very diversity of the field (Luther, 2004b).

In short, here six characteristics of nanotechnology are pointed to that are important for the dynamics of nanotechnology development (see Cientifica, 2003, Selin, 2004, The Royal Society 2004, Wood and Geldart, 2003, Luther, 2004b):

- A platform technology charactherized by boundary problems, where it is contested what is nanotechnology and what is not. It is still discussed whether nano is a new technology or just a hype relabelling existing practices.

- The enabling nature of the technology. It is a very fundamental, (as fundamental as it gets) general purpose technology. There are expectations of wide systemic effects into practically any technology.

- The immaturity and science based nature of the technology. We are mainly talking about fundamental research. The industrial applications of nano science are in many cases only starting to take place and the scope of many potential (theoretically possible) nanotechnologies is highly uncertain.

- The ubiquitous nature of the technology. Being so small nanomaterials can be built into (existing or new) materials and devices to a high degree leading to converging (smart) technologies with multiple functions. It can, however, also be used to built completely new materials.

- The cross-disciplinarity of the field. Nanotechnology is the convergence of several natural scientific disciplines.

- The inherent spectacular nature of the technology. Nanotechnology deals with and changes fundamental aspects of life (atoms and molecules). There are frequent references of nanotechnology to “reshape the world atom by atom” or similar statements. Hype and phantasizing lead to great long term expectations but also confusion and uncertainty and serious concerns on the scope and societal and environmental effects of the technology.

In the Danish empirical analysis in section 5.4 we will return to these issues.

5.2.2 The nanotechnological development

Currently nanotechnology is hardly a technology. A lot of nano science has not materialised into technologies yet. Major problems remain on how to scale up slow research laboratory work to efficient industrial mass production. But internationally, investments into nanotechnology are rising tremendously, illustrating the high expectations to nanotechnology. There is an ongoing global race to be in the lead in a possible coming industrial revolution, currently with the US in front but Asia also very much on the move and the EU lacking somewhat after.

National and local governments across the world will invest close to $5 billion in nanotechnology R&D in 2004 (35% in the US, 35% in Asia, 28% in Europe, and 2% in rest of the world). Corporations will spend about $4 billion globally on nanotechnology R&D in 2004 (46% by US firms, 36% by Asian firms, 17% by European firms, less than 1% by companies in rest of world) (Lux Research, 2004).

Quite a range of products are already commercial, but mainly on a small scale, mostly based on top-down techniques; e.g. in cosmetics, textiles, paints and electronics, many are used in the automotive industry and mobile phones. E.g. in mobile phones nanotechnologies are used in advanced batteries, electronic packaging and in displays. Numerous forecasts have been made on the future development of nanotechnologies. The uncertainty is considerable but major breakthroughs are expected in a range of areas within the next 5 to 15 years though some developments may have even longer time perspectives (Lux Research 2004, Cientifica 2003).

5.2.3 Explaining path creation in nanotechnology

This analysis applies an innovation economic perspective on the nanotechnological development. Basically, the perspective pursued here seeks to place nano innovation dynamics within an innovation system perspective (Freeman, 1987; Freeman, 1995; Lundvall, 1988, 1992 (ed.); Nelson, 1993; OECD, 2000, 2002). The (national) innovation system perspective (NIS) entails a theory on the co-evolution of institutions, organizations and technology. Hence an innovation system is defined as “those elements and relations, which interact in the production, diffusion and use of new and economic useful knowledge” (Lundvall, 1992)[10]. The NIS perspective forms today the basis of much innovation and research policy (OECD, 1999, 2000, European Commission, 2002).

A main question is how nano science is going to be caught up by the (national) innovation system when materialising into technologies. Who are the main actors, what are the drivers and what will the stages of development be? The empirical analysis in section 5.4 seeks to investigate the evolving “nano innovation system” in Denmark, i.e. how research institutes and companies interact in the production of nano knowledge under influence of and in interaction with the surrounding institutional set-up.

Nanotechnology is highly science based. Public research and none the least major multinational companies are currently the main drivers of nanotechnology development, (Lux Research 2004, Cientifica 2003). Being a general purpose technology, similar to the steam engine, electrification and ICT, it is very generic and enables other technologies rather than make up products in its own. Nanotechnologies may serve as e.g. raw materials, ingredients or additives to existing products. Even though nanotechnologies may physically only make up a small portion of various product they may in decisive ways influence on their properties. The nanotechnological development is likely to influence on practically all technology spheres but it is a question how much it will complement or replace existing technologies.

General purpose technologies, if materialized, make profound long term effects on the economy, i.e. create long waves in the economy. The gestation time may be very long though, often 30 to 50 years after the early breakthroughs (Freeman and Loucã, 2001). Wider effect on the aggregate economy only materializes in the mature stages of the technology. So far the economic impacts of nanotechnology are very limited. We are still awaiting a possible technological and economic take off following the current massive worldwide investments in nanotechnology.

The infancy of nano technology means that focus here is on early path creation, i.e. the early structuring of the field. Nano technology is very much in the pre-paradigmatic stage. In this fluid phase the uncertainty as to future innovation paths is great. It is uncertain whether the innovation will become a dominant design or not and there is risk of exaggeration. This makes is difficult to persuade other researchers, firms and investors to support the innovation (Teece, 1986, Lundvall, 1985). Creating confidence in a standard based on a trajectory that is hardly understood, such as nanotechnology may easily appear, is naturally associated with great difficulty. Such radical changes are slow and have to await a codification process and gradual acceptance of principles through multiple interactive learning processes between supporters and opponents.

In the very early stages of a technology, the standardisation activities are focused on the creation of a common language. Next, the performance expectations and procedures for inspection, testing and certification are addressed (Reddy et al. 1989). The codification process may possibly be succeeded by changes in education systems and other supporting infrastructure. In this stage there are weak appropriability conditions and imitation is strong. Market leadership is required to advance standards and it is often big players with a strong reputation who break the logjam among rival technologies and pull the complementary assets (technologies and capabilities) together (Chesbrough and Teece, 1996).

If we turn to the paradigmatic stage, as industry standards increasingly become accepted, economies of scale and learning become more important. Imitators with less developing costs and less restricted by asset specificities, rather than the innovators, may come to possess the dominant design and profit from the innovation (Teece, 1986). Since much nano technology is still only nano science or at the early experimental stage we are talking about very early path creation where industry standards are lacking.

Path-dependent learning implies that a research organisation or firm’s knowledge base is theory-laden and upholding inner consistency. The basic argument is, inspired by Kuhn (1970) that technology development, parallel to scientific work, follows certain heuristics. Dosi (1982 p. 152) defines a technological paradigm as “a model and a pattern of solution of selected technological problems, based on selected principles derived from natural sciences and based on selected materials technologies”, (p.152). A technological trajectory is the pattern of conventional problem solving activity within a given technological paradigm; i.e. it is the normal problem solving activity determined by a paradigm (Dosi, 1982).

The technological path (or trajectory) emerges because the technological paradigm embodies strong prescriptions on the directions of technological change to pursue (positive heuristics) and those to neglect (negative heuristics) (Dosi, 1982). The efforts and imaginations of researchers and practitioners are focused in precise directions while they are “blind” with respect to other technological possibilities. A technological paradigm defines an idea of technological “progress” related to the economic and technological trade-offs of a given technology.

Many elements in the innovation system contribute to the “seeding” of trajectories: “Microlevel entities path-dependently learn (and get stuck).., but sector-specific knowledge bases and country specific institutions restrict the ‘seeding’ of the evolutionary process ..... and also channel the possible evolutionary trajectories .... Given the initial conditions and the institutional context, these innovations spread and set in motion a specific trajectory of competence-building and organizational evolution” (Dosi and Malerba, 1996 p.15).

The core question addressed in this study is on studying the directions of the emerging nano technological trajectories and how environmental issues may form a part in these. The perspective suggested here is to analyze nano path creation dynamics by focusing on the shaping of researchers’ and firms’ attention rules, i.e. the routine focus of their research or technological development work depending on their entrepreneurial expectations, (compare Penrose 1956, Boisot 1995) and their search rules, i.e. their routine learning modes (Nelson and Winther, 1982). The formation of attention and search rules is placed within a wider analysis of the organisation of (nano) knowledge production within the innovation system (Lundvall, 1992 eds., OECD 2000).

These aspects will be further discussed in the analysis of path creation in the Danish nano community in section 5.4.

To conclude, there are limitations as to how much can be said about emerging technological paths in nano technology given the current immaturity in technology development and great uncertainty as to the scope of the technology. We know in fact very little at present about how nanotechnology is going to materialize itself.

5.3 Nanotechnology - international findings on environmental risks and opportunities

5.3.1 Environmental risks related to nanotechnology

Until recently there has been very little research into nano related risks. Thus, health, safety and environmental impact assessment of nanoparticles and nano materials is encumbered with huge uncertainties due to lack of knowledge.

There are, however, increasing attention amongst authorities to nanorelated risk issues and several surveys underway around the globe[11]. In the US national nano initiative, the by far biggest nano research program globally, it is stated that “increasing knowledge of the environmental, social and human health implications of nanotechnology is crucial” (NSET 2003 p.32). In USA, the Office of Research and Development at the Environmental Protection Agency has requested studies to be done on the environmental effects of nanotechnology. French (“ECODYN “) and Asian studies are underway, e.g. in Japan. In its proposal for a European strategy on nanotechnology, the EU Commission (2004b, p. 20) also emphasise the potential risk for human health and the need for research and precaution. A number of research projects on the safety of nanotechnology are being funded by the European Commission within the Fifth and sixth Framework Programme. Among these is the ongoing NANOSAFE project, which assesses the risks involved in the production, handling and use of nanoparticles in industrial processes and products, as well as in consumer products.

Concerns of nanotechnology are particularly related to:

- Their large surface area, crystalline structure and reactivity, which could facilitate transport in the environment or the body which may be difficult to control or could lead to harm because of their interactions with other elements. Some manufactured nanoparticles will be more toxic per unit of mass than larger particles of the same chemical.

- Ultrafine particles have a different biological behaviour and mobility than the larger particles, and there is not a linear relationship between mass and effect. It is likely that nanoparticles will penetrate cells more readily than larger particles.

- The “invisible” size of the particles being developed. Such particles could accidentally enter into the food chain, initially causing damage to plants and animals while eventually becoming a hazard to humans. An expected wide-reaching spread of nanomaterials in products and environment may make them difficult to contain and control (Nanoforum 2004, Jong, 2004, EC Sanco 2004, Royal Society 2004).

The evaluation of risks related to nano particles is complicated by the fact that they exist widely in the natural world already. E.g. resulting from photochemical and volcanic activity and created by plants and algae. Some of these are highly toxic. They have also been created as a by-product by man for thousands of years through cooking and combustion, more recently from vehicle exhausts. The question is then whether manufactured nanoparticles or the use of nanoparticles in new ways present new risks?

The most significant conclusion of the recent/ongoing risk studies is a likely health risk particularly related to free nanoparticles that may penetrate into the brain, lungs and other tissues and possibly cause cancer and other deceases. Nanotubes have properties quite similar to asbestos fibres which raises suspicion of a similar toxicity, (Royal Society, 2004, Nanoforum, 2004, Luther, 2004b, EC Sanco 2004).

Most of the risk studies, however, focus on health and safety aspects while the impacts of nanotechnologies on the environment have not been studied thoroughly yet. The Royal Society report concludes that “there is virtually no information about the effect of nanoparticles on species other than humans or about how they behave in the air, water or soil, or about their ability to accumulate in the food chains” (Royal Society 2004 p.X in the summary). They recommend that until more is known the release of nano particles and nano tubes to the environment should be avoided as far as possible and that a precautionary principle should be applied.

A series of environmental assessment analysis are under way around the globe but so far only few results are available. One of these is an on-going study from CBEN –Rice University examines the behaviour of TiO2-nanoparticles and carbon nanotubes in the environment with emphasis on the interactions with other chemical species. Following on from this, researchers will work on transport and aggregation of nanoparticles as well as their interaction with biological systems (CBEN, 2004). It has been seen that fullerenes could migrate through soil without being absorbed (Nano-forum, 2004). On the other hand not all nanomaterials were mobile in water. The mobility is very case specific (www.nanotechweb.org, 1. april 2004).

A rare example of a finished study is on the ecotoxicological effects of the carbon molecules called “buckyballs” (fullerenes) showing that these cause brain damage in fish at concentrations of 500 ppb (Oberdùrster, 2004). It matters what kind of nanotechnology we are talking about and how ithey are used. According to Put (2004) the following classification can be used for the purpose of mapping out risks related to nanotechnology:

- Nanostructures from whatever nature (nanopatterns, nano-ordering, nanoparticles) that are immobilised at the surface or in the bulk of a matrix material. These kind of nanostructuring creates very little risk as the nanostructures or nanoparticles are fixed in a matrix.

- Nanoparticles that are free and can become airborne to form an aerosol. Depending on the shape of the particles, they can be breathable and upon inhalation cause adverse effects. These effects are related to the enormously enhanced surface to masse ratio and all properties related to surface will be multiplied with a huge factor.

- Supramolecular nanosystems, built up via self assembly, mimicking natural systems. Although these nanosystems might look like natural systems, there is one essential difference; they are not self-replicating and it is unlikely that self-replicating systems will be built up on short notice. There seem currently to be less concern with the so-called “Grey Goo fear” of uncontrolled self-assembly as pointed to by Drexler (1991).

- Nanosystems of natural origin. Natural nanosystems can be extremely dangerous or poisonous. As these systems are self-replicating or belong to self-replicating organisms and moreover as some of them are continuously modifying themselves via exchange of genetic material (e.g. viruses), these nanosystems have to be considered as the most dangerous on this planet, although this is not perceived as such. Genetic modification of certain natural systems is done because it can enhance beneficial properties substantially (e.g. enzymatic catalysis). However, new insights in genetics led to the conviction that not all consequences of even simple genetic modifications can be predicted; therefore, genetic modification should be limited to micro-organisms for which containment is possible.

The above categorization says, however, little about the environmental impact of different nano manufacturing techniques and thereby also of different nanotechnologies and nanomaterials. Of this very little is known so far. The Nanoforum 2004 report states: “Differences in size, shape, surface area, chemical composition and biopersistence require that the possible environmental impact be assessed for each type of nanomaterial. The long-term behaviour of such substances and their effects on elements are thus extremely hard to foresee”.

Table 5.1 summarises the results of an environmental assessment performed in Germany by IÙW on the different nano manufacturing methods, one of the few studies made on this so far. As shown it is anticipated that risk of release of nano particles is low for most productions and uses of nanomaterials. Highest risks occur in work environments when processing airborne nano particles. However, even if the release from materials may be low, a widespread use of nanotechnology may possibly lead to a dispersion of significant amounts of nano particles. We need to know more about the behaviour and potential hazards of artificial nano particles in the environment.

Table 5.1 Nanotechnological products, their probable manufacturing process and their potential hazards.

| Nanotechnology based products | Nanostructure | Manufacturing process | Potential hazards | Industrial sector |

| Application Area: New Surface Functionalities and Finishing | ||||

| tribological layers: e.g. superhard surfaces | ultrathin layers; nano-crystallites; nano particles in an amorphous matrix | vapour phase deposition, PECVD | PVD/CVD production process: risk of disposal of nano-particles is small (process is running in a vacuum environment) use stage: low scale disposal of nanoparticles possible |

Engineering, automotive |

| thermal and chemical protection layers | ultrathin layers; organic-inorganic hy-brid-polymers; nanocomposites | vapour phase deposition; sol-gel | aerospace, automotive, ICT, food | |

| self-cleaning and antibacterial surfaces | ultrathin (polymer) layers, nanocrystallites in an amourphous matrix | vapour phase deposition, sol-gel, soft lithography | textile, ICT, food, building, medicine... | |

| scratch resistant and anti-adhesive surfaces | ultrathin layers; organic-inorganic hybrid-polymers | sol-gel; SAM | use stage: low scale disposal of nano particles possible | building, automotive, textile, consumer goods |

| products with "nanoparticle effects" : e.g. colour effects in lacquers | nano-particles, ultrathin layers | flame assisted deposition, flame hydrolysis, sol-gel | production: deposition possible; use stage: low scale disposal possible |

building, automotive, consumer goods, textile |

| Application Area: Catalysis, Chemistry, Advanced Materials | ||||

| catalysts | nanoporous oxides, polymers or zeolithes; ultrathin layers | precipitation, sol-gel, SAM, molecular imprinting | not known | chemistry, automotive, environmental, biotech |

| Sieves and filtration | sintered nano-particles, nanoporous polymers | self assembly, colloid chemistry | chemistry, environmental | |

| Application Area: Energy Conversion and Utilisation | ||||

| fuel cells | ceramics from sintered nano-particles | div. | not known | energy, automotive |

| Super-capacitors | Nanotubes, nanoporous carbon aerogels | div. | nanotubes possibly toxic when inhaled | energy |

| superconductors | ultrathin layers | e.g. vapour phase deposition | production: risk of disposal is small | energy, medicine |

| Application Area: Construction | ||||

| nanoscale additives: e.g. carbon black in car tires | nanocrystals and –particles | flame assisted deposition, flame spray pyrolysis | production process: disposal of nano particles possible, danger of inhaling for workers; use stage: low scale disposal of nano-particles possible |

building, automotive |

| Application Area: Information Processing and Transmission | ||||

| nanoelectronic components | ultrathin lateral nanostructured semiconductor | PVD, CVD, lithography | PVD/CVD production process: risk of disposal of nano-particles is small | ICT |

| Displays | utrathin layers | PVD, spin-coating | ICT, automotive | |

| Application Area: Nanosensors and Nanoactuators | ||||

| sensors: e.g. GMR-sensors | metallic ultrathin layers; ultrafine tips | CVD/PVD/MBE; etching, SAM | PVD/CVD production process: risk of disposal of nanoparticles is small | automotive, engineering, ICT, analytics |

| Probes e.g. for scanning tunneling microscope | utrathin layers, ultrafine tips and molecules | PVD, etching, SAM | analytics | |

| Application Area: Life Sciences | ||||

| active agent carrier: e.g. drug carriers | organic molecules, nanoporous oxides | self assembly, anodic treatment | flame hydrolysis production process: disposal of nano-particles possible; use stage: particles might be absorbed dermally; very small TiO2-particles possibly toxic | Pharma, medicine |

| Cosmetics: e.g. pigments | utrathin layers from nano-particles, (amorphous) nano-particles | wet-chemical separation; colloid chemistry | cosmetics | |

| sunscreen | nanocrystalline titanium dioxide (TiO2) | flame hydrolysis | cosmetics | |

Source: Haum et al., 2004.

5.3.2 Environmental impacts in the product cycle

Life Cycle assessment is an environmental management tools for assessing the environmental impacts of a service or function. All use of materials, resources and energy as well as all emissions from the processes in the life cycle are aggregated and interpreted in terms of their impacts on the environment and health, e.g. their contribution to global warming, acidification etc.

As described above specific concern is related to the release of free nanoparticles. An inventory of possible sources of potential particle release from the use and production of nanoparticles can be made by addressing the life cycle from nanoparticle generation to end products and finally disposal. It shall be stressed that due to the variety of different production methods, the process conditions vary widely and thus in principle the risk of potential particle release has to be considered separately for each different process.

The following main steps can cause unintended release of nanoparticles: (Luther, 2004c, p. 44-48):

Nanoparticle production: Processes working at high temperatures or with high energy mechanical forces, particle release could occur in case of loss of containment of the reactor or the mills. The large quantities of nanopowder could be released in a short time into the atmosphere. Moreover, when sealing is broken, reactive mixtures can be put in contact with air and in some cases cause violent exothermic reactions. Failure of collecting apparatus are also important sources of potential release; this apparatus must be able to stop the nanoparticles and to evacuate effluents produced from the processes.

Collection of nanoparticles: Risks are increasing during the collection of nanoparticles particularly in a dry form. When opening collecting apparatus or reactors, nanoparticles can be released and airborne dispersed due to their high volatility. In gaseous atmosphere the behaviour of dry nanoparticles is primarily determined by the balance between attractive and lift forces. Gravity force has no noticeable effect on nanoparticles. Therefore, nanoparticles may be an air contaminant for a long time potentially being an inhalation health risks. When handling small particles the conditions for dust explosions may arise, especially in case of metal powders. Once dust has formed into the proper mixture with air, it can be ignited by energy from various internal or external sources. During the collection of solid nanopowders special care must be taken with regard to ventilation at the working place. Air streams could disperse nanopowders to form aerosols.

Cleaning operations: Nanoparticle release can also occur during cleaning operations of reactors, after the disassembling, when nanoparticles have to be removed from stainless steel pieces, windows or filters. Cleaning is usually performed using solvents or water, tissues, brushes or sponges, which are then discarded in garbage cans.

Handling and conditioning operations: Risks related to this kind of operations can be release of nanoparticles while producing ceramic pieces, particularly when the compressed nanopowders or coatings are formed.

Waste disposal: This includes the total production equipment that has been in contact with nanopowders at the different production steps. Disposal of the waste might be a potential source of nanoparticle release into the environment if no special care is taken with traceability and final disposal or combustion of the wastes.

Final product utilisation: When final nanoparticle based products are obtained, risks depend on the way in which nanoparticles are integrated. For nanostructured materials, nanoparticles are linked to a matrix by a thermal treatment at high temperatures. However, under wearing conditions particle release is likely to occur but dissociation of matter at the nanometric scale is unlikely.

Some of the fundamental features of nanotechnology which are essential for the new opportunities nanotechnology offers may also be a drawback when it comes to risks. We have a natural fear of what we cannot see, cannot control and cannot understand. And this is how nanotechnology may easily appear.

5.3.3 Policy initiative on nano environmental risks

Existing regulation indexing chemicals and measuring new products toxicology need to be adapted to the special properties of nano materials. According to Nanoforum (2004) nanotechnology leads to a need for new norms, standards and testing procedures for assessing risks to the environment and health (e.g. for nanometer length scales, calibration of instruments, health effects of nanoparticles, toxic effects of nanometer size of particles rather than on their chemical composition).

Considerable amount of attention is recently being devoted to the issues of regulation and legislation of risks related to nanotechnology particularly in USA and Europe. However, practical set-up of new legislation or adaptation of existing legislation is still in its infancy. It can be said that most countries and international institutions are still in the phase of raising awareness and investigating what the regulated topics should be (Nanoforum 2004).

The European Parliament's Industry, External trade, Research and Energy Committee has called for a study on the need for new regulations on nanotechnology while the same subject is to be discussed by the UK's Parliamentary and Scientific Committee.

In the nanostrategy of the European Commission from 2004 the following actions are recommended in relation to public health, safety, environment and consumer protection (p.20):

- to identify and address safety concerns (real or perceived) at the earliest possible stage

- to reinforce support for the integration of health, environment, risk and other aspects related to R&D activities together with specific studies

- to support the generation of data on toxicology and ecotoxicology (including dose response data) and evaluate potential human and environmental exposure

- the adjustment, if necessary, of risk assessment procedures to take into account the particular issues associated with nanotechnology applications

- the integration of assessment of risk to human health, the environment, consumers and workers at all stages of the life cycle of the technology (including conception, R&D, manufacturing, distribution, use and disposal) (European Commission 2004b)

The Danish Nano action plan made by the recent Nano Technological Foresight suggests that there should be a focus on studies of possible health hazards and environmental and ethical aspects associated with nanotechnological industrial processes and materials and other applications of nanotechnology (Videnskabsministeriet, 2004). The Nano Action Plan “recommends that as an integrated part of each individual project, funds should be allocated to research and competence-raising relating to the environmental, health and ethical issues raised by nanotechnology, and that the responsibility for this should rest upon the research environments that receive project funding. Projects should only be granted funding if they address the environmental, health and ethical aspects in a responsible manner” (Ministeriet for Videnskab, Teknologi og Udvikling 2004).

5.3.4 Environmental opportunities related to nanotechnology

There are often very high expectations as to the environmental benefits from nanotechnology in nano reports and policy statements (see e.g. The Royal Society, 2003, Masciangioli, 2002, Nanoforum, 2004, Luther, 2004b, NSET 2003). In fact there are few nano reports if any, which do not mention environmental opportunities as a core benefit of the technology. This is also the case with the recent Danish Nano Foresight report (Videnskabsministeriet 2004). There seems in other words to be an unusual strong linkage between nanotechnology and environmental benefits.

Some of these reports point to some fundamental features of nanotechnology with eco-potentials. E.g Nanoforum (2004), argue that self-assembly, i.e. the attempt of mimicking nature’s intrinsic way to build on the nanometre scale molecule by molecule through self-organisation, has eco-potentials:

“This “assembling” method is extremely efficient and could be helpful for the conservation of nature and natural resources. It is expected that the concept of “self-assembly” could be an approach for a sustainable development in the future. However, such futuristic concepts are far from being realised at present or in a medium term view (Nanoforum 2004 p.39).

Another report points to the energy efficiency of nanoparticles:

“The most relevant effect of nanoparticles for energy applications is the large amount of the atoms exposed on the surface compared to the bulk material. The large surface area leads to a high reactivity with low material use, which is useful for better catalysts (leading to higher reaction rates, lower processing temperatures, reduced emission or need for less material), for improving combustion processes (higher efficiency, lower processing temperatures, or higher absorption rates for light” (Nanoform, 2003, p.89).

The big US National Nano Initiative holds a strong overall green vision: “Nanoscale science and engineering can significantly improve our understanding of molecular processes that take place in the environment and help reduce pollution by leading to the development of new “green” technologies that minimize the use, production and transportation of waste products, particularly toxic substances. Environmental remediation will be improved by the removal of contaminants from air and water supplies to levels currently unattainable, and by the continuous and real-time measurement of pollutants” (NSET 2003 p.32).

Another grand and quite green vision is expressed by a nano roadmap of the chemical industry stating that in the longer term it is hoped that “nanomanufacturing will encompass genuine ”green” concepts of zero waste and little or no solvent use incorporating life cycle concepts of responsible products coupling biology with inorganic materials” (www.ChemicalVision2020.org).

Jacobstein (2001) and Reynolds (2001) pinpoint perhaps most sharply four main features of nanotechnology that are likely to lead to environmental benefits:

- The atom-by atom construction of nanotechnology will allow the creation of materials and products without dangerous and messy by-products.

- Most products of nanotechnology will be made of simple and abundant elements, e.g. carbon is the basis of most nanomanufacturing.

- Less materials will be needed because nanomaterials are stronger and thinner

- Cheap nanomaterials of very high strength to weight ration could mean a marked drop in energy consumption e.g. in transport.

Malanowski (2001) referring from the results of a workshop similarly concludes that the ecological benefits of nanotechnology could be very large in the form of:

- A preservation of resources is expected through the production of minituarised products which with a smaller material expenditure fulfils the same functions as conventional products.

- Energy savings could be achieved in transport through weight and volume reduction of products and by the reduced consumption costs of energy sparing electronic production processes.

- The use of wear resistant machine parts, corrosion-proof materials, nano-lubricants and/or nanotechnological procedures for the smoothing of surfaces contributes to the service life extension of machines.

- New materials will show a larger stability with comparatively small specific weights than conventional materials and will likewise contribute to the preservation of resources and e.g. reduced fuel consumption in cars.

The claims, as here, are often of a quite general and theoretical character, and many analyses are merely based on workshops rather than thorough analysis. There is a lack of more careful and systematic in depth studies of the extent and nature of the eco-potentials. This is naturally related to the early stage of development of the nanotechnologies and the associated high uncertainty. It seems to be too early to be very specific about where the opportunities are. And/or the eco-opportunities have not been looked into properly so far.

Numerous more specific potential environmental benefits of nanotechnology are pointed to in the literature, though more as examples and visions than an attempt to be comprehensive or to identify the most significant environmental potentials. Some of the frequently mentioned are (The Royal Society, 2003, Masciangioli, 2002, Nanoforum, 2003 and 2004, Luther, 2004b, Antón, et al 2001, Malanowski, 2001, European Commission 2004, NSET 2003):

Reduction of energy consumption

- Through a) better insulation systems using nano porous materials, b) more efficient lighting, nanotechnological approaches like LEDs (Light Emitting Diodes) or QCAs (Quantum Caged Atoms) are much more energy efficient c) more efficient combustion systems, d) the energy consumption in the mobility sector can be reduced by the use of lighter and stronger nano structured materials (see the automotive industry below), e) synthetic or manufacturing processes can occur at ambient temperature and pressure.

Develop more efficient or renewable energy production

- The degree of efficiency of combustion engines is not higher than 15-20% at the moment[i]. Nanotechnology can improve combustion by designing specific catalysts with maximised surface area.

- Nanotechnology is important for the development of hydrogen energy systems in several ways. Attempts are made at developing fuel cells powered by hydrogen fuel. The catalyst in fuel cells is nanostructured materials consisting of carbon supported noble metal particles with diameters of 1- 5 nm. Suitable materials for hydrogen storage contain a large number of small nanosized pores. Therefore nanostructured materials like nanotubes, zeolites or alanates are under investigation.

- Nanotechnology can help to increase the efficiency of light conversion in solar cells by specifically designed nanostructures (the implementation of Nanodots). A widespread use of solar cells suffers from the high costs of purchase. An alternative nano technological approach under development is low cost solar cells using titanium dioxide nanoparticles as light absorbing components (Grätzel cells) which may allow for more decentralised energy supply systems.

Reduction of resource consumption in the production or user phase

- Nanoparticles in paint can induce new properties to the paint, e.g. cooling effects, self cleaning and self repairing surfaces

- Nanotubes (or fibres build from them) can be used as reinforcement for composite materials. Because of the nature of the bonding, it is predicted that nanotube-based material could be 50 to 100 times stronger than steel at one-sixth of the weight if current technical barriers can be overcome.

- Strengthening of polymers in order to produce new materials with less consumption of raw materials which can substitute existing materials

- Reduced use of rare resources, e.g. precious metals, or toxic substances in catalysts.

- Textiles with nanotechnology finish can be washed less regularly and at lower temperature

Improved cleaning of air, water and soil

- Through the development of new environmental catalysts and improved catalytic processes. As well as improved capability to tailor nanostructured membranes offering new opportunities to selectively extract contaminants from air, water and soil.

Improving recycling

- The use of batteries with higher energy content or the use of rechargeable batteries or supercapacitors with higher rate of recharging using nanomaterials could limit the battery disposal problem.

- Integration of nano-chips in materials and products containing information about material properties and composition can be used for recycling purposes. (There are, however, also arguments that multifunctional nanoproducts may be difficult to recycle).

Better monitoring

- Nanotechnologies are expected to enable the production of smaller, cheaper sensors with increasing selectivity, which can allow continuous measurement and be used in a wide range of applications, e.g. monitoring the quality of drinking water, detecting and tracking pollutants in the environment.

Reducing the environmental impact of the automotive industry

- One area where nanotechnology is expected to contribute with major eco-innovations is in the automotive industry (Nanoforum 2004). Rising traffic density means that transport remains a major environmental problem and the car industry is increasingly looking for new solutions, also among nanotechnologies. The car industry hence belongs to the earliest users of nanotechnology. The automotive industry is in other words an area where there are some more substantial insights and experiences with developing eco-innovations based on nanotechnology. These are therefore dealt with more in detail in the following. Some products mentioned below are already on the market, others are at the experimental level.

- Energy consumption and waste is reduced by replacing metals with lighter materials. Nanoparticles are used to improve the strength of lighter metals or of steel, so that less metal is necessary.[1] Or using polymers reinforced with nanoparticles making them stronger per unit weight.

- The rolling resistance of tyres is lowered saving energy, and the durability is improved by use of nanoscaled carbon black saving waste.

- The combustion can be improved by homogenous and large area spraying of the petrol. An injection system with very fine holes (Nanojets) is under development.

- The engine lubrication is optimised by new nanoparticle-based lubricants and through micro- and nanostructures on the inner surface of the cylinders.

- The engines efficiency is optimised by use of higher temperatures and pressures. Nanotechnology can help to develop materials which are resistant to these conditions.

- Use of environmental more friendly energy systems in cars. Thermoelectrical elements based on nano-crystalline layers of semiconductors with low bandgaps may use a part of lost heat in the future. Cheap (e.g. Dye solar cells) or more efficient types of solar cells (e.g. by the implementation of Nanodots) can be used in the roof for operation of specific modules (e.g. for air conditioning systems), possibly be enlarged to the whole chassis. Experiments with cars driven by fuel cells are extensive.

- Reduction of air pollution caused by exhaust gas. Nanotechnology can contribute to the further reduction of pollutants by nanoporous filters, which can clean the exhaust mechanically, by catalytic converters based on nanoscale noble metal particles or by catalytic coatings on cylinder walls and catalytic nanoparticles as additive for fuels.

- Developing new understandings of molecular processes that take place in the environment, e.g. how contaminants move through the environment, is also highlighted as an important environmental benefit of nanoscience (NSET 2003).

Overall, the environmental benefits of nanotechnologies are as yet not described in very great detail, and life cycle assessments are often lacking, i.e. investigating the environmental impacts of nanotechnologies over the complete supply chain including disposal.

A few case studies have been made looking more in depth at the eco-potentials of nanotechnology, noticeable a recent German life cycle assessment study (Steinfelt et al., 2004). They have analysed four case studies: Nano varnish, nano innovation in styrene synthesis, nano in the display sector and nano in the lighting sector. The study illustrates that at this point it is very difficult to make high standard quantitative assessments of the environmental impact of nanotechnologies due to lack of knowledge, incompleteness of available data on a given product or process and the high uncertainty as to the future technology development.

The most important recent environment assessment report , the earlier mentioned Royal Society report (2004) does not look into the eco-potentials, except for stating that “it is important to substantiate such [environmental] claims by checking that there are indeed net benefits over the life cycle of the material or product” (Royal Society 2004 p.32). They recommend a series of environmental assessment studies be undertaken on existing and expected developments in nanotechnologies by independent bodies.

Policies towards nanotechnology, e.g. EU’s nano strategy, and the Danish suggested nano action plan, mainly focus on risk issues when dealing with environmental impacts and do not aim to address barriers to eco-innovation. So although the eco-potentials of nanotechnology are highly praised they seem rarely to be promoted by policies. An important exception is the US National Nano Initiative where “Nano Scale Processes for Environmental Improvement” makes up one out of nine Grand Challenge Areas for prioritized research, compare also the already mentioned strong green vision of the research program (NSET 2003).

Interestingly a first international initiative “International Consortium for Environment and Nanotechnology Research (I-CENTR)” has been created recently which looks at both negative and potentially positive environmental impacts of nanotechnology. The consortium studies the environmental applications of nanochemistry, nano-scale materials and processes in the environment, nanomaterial interactions with organisms and environment and generally sustainable ways for nanotechnologies. This consortium gathers approximately 30 researchers from different French and US universities and it is adding groups in Germany, Switzerland and England. Currently the actual extent of nano research and development targeted at eco-innovation is not known[12]. To conclude, also when it comes to eco-potentials there are many visions and claims related to nanotechnology but there is so far limited knowledge on the more specific potentials of nanotechnologies.

In section 5.5 when focusing on the eco-potentials identified by Danish nano researchers, the eco-potentials will be discussed further.

5.4 Danish findings on path creation in nanotechnology

This section presents the main empirical findings on the role of environmental issues in the search processes of Danish nano researchers and industry. The empirical analysis undertaken is a first scoping study into the actors and dynamics of nanotechnology development in Denmark based on an interview round in the Danish nano community. No prior innovation analysis of this character has been made before, so there is little data to build on or relate to. Given the broadness of the technological field there are limits as to the depth of the analysis possible within this relatively limited project. The emergence of the Danish nano community

In recent years much is happening in the nano area in Denmark. Several new nano research centres and networks are springing up. The biggest ones are Nano•DTU with the major subcentres -MIC, COM, ICAT and CAMP at the Technical University of Denmark, iNANO at the University of Aarhus with links to Ålborg University and the Nano-Science Center at the University of Copenhagen . Some of these have been around for a while, 10-15 years, others are new. Also several transdisciplinary “nano educations” and PhD schools have been established and with great success, despite the general declining interest in the natural sciences among students. At the structural level, then we clearly see the emergence of a nano research community.

These new centres reflect that some Danish funding in the latter years have been earmarked to nano research, last year 60 mio. DKr, making the “nano” term increasingly attractive to researchers but forcing the nano researchers to join groups to apply for the money. There is little tradition in Denmark for large focused research efforts. Recently The Danish Basic research Fund and the new High Technology Fund is changing this somewhat, illustrating a stronger political interest in research and noticeably high technology in Denmark, including none the least nano research. There are therefore expectations of more funding going into the nano field. As an input to the priorities of the High Technology Fund, the recent Danish nano technological foresight has suggested to focus the nano effort into two strong nano research centres with a budget of at least 100 mio. DKr/year. The outcome of these research strategic processes is, however, as yet unknown.

But how much hype and how much scientific novelty is related to this nano trend? The Danish nano researchers generally are sceptical about the hype related to nanotechnology and its implications. To a large degree many feel there is nothing new in nano. They do the research they have always done but now it is redefined as nano.

On the other hand the same researchers also have expectations of nano science leading to greater changes in technology development and for some even expectations of an industrial revolution, albeit of a more evolutionary character. There is, in other words, a widespread sense of novelty and expectations of new industrial opportunities. Quite many, however, express scepticism about the scope of industrial effects, and warn that the hype may lead to too high expectations to nanotechnology and a back lash, especially in the short term.

At the more cognitive level, even though this may not be recognized by the individual researcher, a general conclusion of this analysis is that attention rules are changing as still more researchers, and more hesitantly people in industry, look towards “the bottom” leading to new problem definitions.

And also search rules are changing in important ways. Partly because researchers applying the new nano tools towards their research area are growing new understandings of how the size (of clusters) matters for the properties of materials. Theory building and modelling is replacing trial and error experimentation in a range of areas, eg. catalysis. Partly because of the transdisciplinary nature which is recognized as taking a central role in much nano science. It seems researchers from various disciplines find new grounds to meet at “the bottom” and synthesize their disciplines in new ways.

Danish researchers expect that the major innovations springing from nanotechnology will be related to the boarder areas between different disciplines, especially between biology – learning from natural systems- and physics/chemistry. New more transdisciplinary paths are therefore to be expected. The effect of this, new search rules in various nano related technological areas are, however, only in the making. The uncertainty about the direction of nanotechnological paths at this time is still huge.

In all, there are overall signs of new patterns of problem-solving activities emerging meaning that nano is not only a language (a redefinition of existing practices), it is a technological trajectory, a trajectory that is however, strongly shaped by the expectations associated with the nano hype.

These conclusions are likely to apply generally to nanotechnology and not only to Danish conditions. In fact Danish researchers state that there is no such thing as a specific Danish approach to nanotechnology; it is basic science and very international and regional specialisation is limited. There are of course key Danish competencies and perspectives as we shall return to.

5.4.1 The organisation of the nanotechnological knowledge production in Denmark

Much too is happening on the organisation of nano knowledge production as the field starts to shape up which calls for a deeper investigation. Here only a few preliminary observations will be made.

The Danish innovation system is generally fairly low tech. There is a specialisation on relatively low and medium tech products and an overweight of small companies and few really big companies. Still Denmark belongs among the more innovative economies and is doing quite well, none the least through user-driven innovations and further developments of products, albeit little engaged in radical innovation (Lundvall, 1999, the Innovation Scoreboard 2004). This raises questions as to the potential and conditions for building competencies on nanotechnology in Denmark given that nanotechnology belongs among the most science-based and high-tech technologies.

The Danish Nano Foresight Report especially points to characterization as the core competence within nano science and nanotechnology (Ministeriet for Videnskab, Teknologi og Udvikling, 2004). That is understanding and describing the phenomenon of nature and physics, while there traditionally has been less focus on synthesis that is the use of these understandings for the creation of new materials and other technologies. The core nano competencies identified are within traditional natural sciences such as theoretical physics, quantum physics, optoelectronics, scanning probe microscopi, X-ray diffraction and biomolecules. Measured in publications the Danish nano research is at a medium level seen in an international context, but it is in the top on some areas such as catalysis. It has been less good at translating this knowledge into industrial applications. This is, however, seen as an advantage, as nanotechnology development is taking place closer to the world of fundamental physics research than the traditional industry world (Ministeriet for Videnskab, Teknologi og Udvikling, 2004).

Still, some nano researchers criticize the Danish nano research for being generally too little oriented towards industrial application. A researcher at the Technical University states: “In Denmark nano research is about understanding, modulization and characterization more than manufacturing. What we are in want of in Denmark is a center for the design of nano materials. There are companies around the world becoming rich from selling nano tubes, fullerenes and tailor made materials. I see no reason why we shouldn’t make this in Denmark”.

There are some facilities and companies involved in nanomanufacturing in Denmark. E.g. Danchip is Denmark’s leading facility for micro- and nanotechnology, who uses conventional silicon integrated circuit technology for new areas within micro and nanotechnology. Danchip is a part of Nano•DTU. It has however, not been possible to make a mapping of the Danish nanoequipment and manufacturing facilities in this study.

Innovations based on micro/nano fabrication technology play a rising role over the last few years: “Danish Micro- and nanofabrication points both to applications within telecom and improving the bandwidth of the Internet, but also to new exciting possibilities with lab-on-a-chip applications, where complex diagnoses could be performed directly at the practitioner’s office.” (Professor Jens K. Nørskov, head of Nano•DTU)

The Danish nano research primarily takes place within the main public universities and research institutes in Denmark, compare the mentioned nanocentres and networks, i.e. mainly within the Technical University of Denmark (DTU), the University of Aarhus (AU), the University of Copenhagen (KU) and Risoe National Laboratory, and some what less so at the Royal Veterinary and Agricultural University of Denmark (KVL), Ålborg University (AAU) and Southern Danish University (SDU). Also the technical institutes (“Godkendte Teknologiske Institutter”) are to some extent involved in nano research with a strong application orientation.

With one exception research within business so far plays a minor role, although the relatively few big and research oriented manufacturing companies in Denmark to various degrees are involved in nano science and technology development and cooperate with the universities. Most important are companies within catalysis, medico and pharmacy, somewhat less so the advanced machinery and electronics industry and food ingredients. We are talking about in all less than ten big companies who are involved in nano research, and who are in a formal collaboration with universities, often in the form of co-financing PhDs. Some of these companies are, however, quite important to Danish nano research. Several nano researchers express that they miss the local presence of more big companies with strong scientific competencies to widen the opportunities for collaborative research with industry.

The one big company standing out by playing a central role in Danish nano research and technology development is Haldor Topsøe, a world leading producer of environmental catalysts and steam reforming. Haldor Topsøe has 30 years of experience with large scale nano based production within catalysis. Catalysis is a traditional nano scale technology, being well developed through experimentation long before the talk of “nano science” started. Much of Haldor Topsøes research and technology development has accordingly been based on experimentation. The new understandings originating from the rise of nano science the last 10-15 years are only beginning to make an impact on the Haldor Topsøe technology development, and they are still waiting for major breakthroughs resulting from this.

Haldor Topsøe has a very close relationship with the Danish research institutes, especially at the Technical University (Nano•DTU) and University of Aarhus (iNANO), somewhat less also Risoe. The relationships are formal and so close they could be called symbiotic. Haldor Topsøe pursues a conscious strategy of promoting Danish nano research and education, which they see as a necessary investment to them.[13] They not only collaborate with research institutes but also seek to strengthen these. E.g. in 1987 they took the initiative together with DTU to start the research of Surface Science at DTU. This later materialized into CAMP and later also into the ICAT center in 1999 focusing on catalysis. These and also the new Danish Research Foundation centrer CINF (Center for Individual Nanoparticle Functionality) are very close collaborators with Haldor Topsøe A/S. Halder Topsøe also invests in equipment at the universities, e.g. a new Electron Microscope costing 25 mio. Dkr. It is central to Haldor Topsøe’s competitive strategy to have a better understanding than their competitors of the catalytic processes.[14]

Haldor Topsøe is characterized by the nano researchers as being unique in its long sightedness and very strong research orientation, originating back to the founder’s strong passion for research. Ib Chorkendorff, head of the ICAT and CINF centre, states:

“A company like Topsøe is different because of the philosophy there, which is very research based. Our competitors in Germany and England for example also cooperate with companies but these don’t have the same interests in research. You can see a difference in the labs. The other catalyst plants haven’t used so much money on equipment; they can’t make the interesting investigations that Topsøe can make. This is what makes them so interesting as learning partners. We can talk to them directly. There are people there doing the same kind of research as we do. It is also interesting for our candidates who can see a career opportunity. This is what makes Topsøe a unique company. The close ties with industry are essential for our research.

He emphasizes the need to continue and strengthen the shift from the trial and error approach to more fundamental research within catalysis in the rising global competition:

“We don’t have a chance to compete with the Chinese who mix lots of potential catalysts over and over again looking for successful candidates. We need to find out what exactly the problem is, look at the physics behind it and then find out something new”.

General contact and cooperation with business various considerable, some nano researchers have hardly any contact, others quite a lot. Industry links are somewhat stronger at the application oriented Technical University and Risoe National Laboratory than at the traditional universities. A new analysis undertaken for the Danish Ministry of Science, Technology and Innovation confirm that these two institutes are in the lead in Denmark when it comes to business contacts, spin offs and commercialization of the research undertaken generally[15]. The large Nano•DTU center seeks consciously to promote technology transfer to companies and has collaborations with around 50 Danish and international companies[16]. Relations to business seem to be changing. “I see things are changing these years. Fifteen years ago the opinion was that here [at the university] we were to perform research at the highest level and educate people to the highest level, and that wouldn’t be possible if companies were involved. Today university researchers are much more open to interaction with business.” (Researcher at iNANO.) Another researcher at iNANO states: “Earlier we had very little contact with industry, but now [since joining a think tank on nano application opportunities in the food industry last year] relations are very good. It has been quite an eye opener to learn about their needs”.

The Danish nano foresight report mapped 54 Danish companies working with or showing a strong interest in nanotechnology (Ministeriet for Videnskab, Teknologi og Udvikling, 2004). Most of these are small spin-offs from the universities and/or small companies within nano instrumentation and measuring. Additionally, we have the early users of nanotechnology, i.e. the large innovative companies in Denmark, who cooperate with nano researchers on many of their projects. Actual industrial application of nano research is, however, still limited. Generally, the industrial uptake of nanotechnology is very limited in Denmark with the exception of the field of catalysis, in which, as elsewhere in the world, we are still far from widespread industrial application and up-scaling to mass production.

Also company attitudes towards cooperation seem to be changing. When discussing perspectives for a wider industrial nano development in Denmark, Professor Besenbacher, Head of iNANO states: “I am very positive about cooperation with industry. It merely requires openness and a visionary attitude among the leading Danish companies. I clearly sense a considerable interest for nano, an interest which has increased over the past years. I think that the companies gradually realize that universities are leaders in this field, and they thus have a tremendous interest in interacting with us.”

A greater role is, however, expected from the established companies than new ones. Professor Besenbacher states: “The future role played by small start-up companies is yet unclear. The challenge is to go from fundamental blue sky research to industrial production, and with a time horizon of three years, there is no proof of concept, making it difficult to obtain financing in Denmark. It is much easier to attain risk capital in the US”.

A range of small, dedicated nano companies, however, have emerged, as illustrated by table 5.2 in section 5.5, especially within sensors, nanometrology and nanoparticle production. These are typically spin-offs from the universities/research institutes. Their role in the uptake of nanotechnology in industrial production remains to be seen.

5.4.2 The Danish learning relations

The rise of the nano technological field is changing the learning relations in Denmark in important ways. Ib Chorkendorff, Head of ICAT at the Technical University states: “It is not a single or particular event or invention that has happened, which makes nano into something special, because we operate within the same circles as we have done the whole time focusing at the atomic design. If I should say something about the nano hype it is more that it leads to greater fragmentation; because every university wants its own nano centre.The new nano constellations mean that things have become more rigid.

Cooperation between the new nano centres has to some degree diminished, particularly between Århus/Jutland (iNANO), and the research environments on Zealand (especially the Technical University). At the new Nano Centre in Copenhagen they are now also looking towards Sweden (the Øresund region) for new cooperation opportunities.

The new regional nano centres to some degree disturb existing knowledge relations, since the thematic specialisation does not follow the regional clustering closely. In other words nano research into the same themes is performed in more places in Denmark.

All in all, the new nano centres have a marked impact on the organisation of knowledge production, both negative and positive. On the positive side, the new nano centres are valued by the researchers within them, particularly because they facilitate interdisciplinary work. Actually bringing together researchers from various fields on a daily basis creates new opportunities for in-depth, long-lasting collaboration. The interdisciplinary way of working is surrounded by excitement. For example, a project on biocompatible materials at the iNANO centre in Århus bought together a molecular biologist, a physicist and a medical doctor. In the beginning they did not understand each other due to their different scientific backgrounds, but now they are getting somewhere: “It is quite new for us to operate with the interaction between solid surfaces and cells and proteins, but it has opened up completely new possibilities and has been quite exciting”, (Researcher, iNANO centre).

Nano•DTU, the largest cross disciplinary center for nanotechnology in Denmark, was established in 2004 to create synergy between the different research groups working in nanotechnology at the Technical University and use competencies and nanofacilities across departmental walls. More than 170 researchers are members of Nano•DTU, coming from 9 different departments and around 14 different research groups, illustrating the wide research span of nanotechnology.

The nano centres have had a major positive impact on the ability to attract funding, researchers and interest from companies. The iNANO centre, although only 2½ years old, sees a clear advantage in being well branded both nationally and internationally, especially in being more visible to companies.

Generally, learning relations between various departments at the same university/research institutions working with nano seem to be quite strong and are strengthened by the new shared nano profile and the need to join forces to look for funds. Learning relations with international learning partners are also important, especially EU partners in order to apply for EU funding. It is less relevant when it comes to cooperation with industry.

Nano-related research takes place at all Danish universities, at least if we do not define nanotechnology too rigidly. Research outside the new centres have problems in attracting funds and attention, e.g. for researchers at the agricultural university.