Survey of Chemical Substances in Consumer Products, No. 91, 2008

Survey of chemical substances in headphones and hearing protection aids

Contents

4 Description of the product groups

5 Survey of the market for headphones

- 5.1 The market for headphones

- 5.2 Identification of producers of headphones

- 5.3 Information from producers

6 Survey of the market for hearing protection aids

7 Materials in headphones and hearing protection aids

- 7.1 Materials in headphones

- 7.2 Materials in hearing protection aids

- 7.3 Summary – survey of materials

8 Analysis of selected products

- 9.1 PVC (polyvinyl chloride)

- 9.2 PUR (polyurethane)

- 9.3 Artificial leather

- 9.4 Silicone

- 9.5 Textiles

- 9.6 ABS

- 9.7 Rubber and thermoplastic elastomers

10 General assessment of possible risks by use of headphones and hearing protection aids

11 Proposal for analysis and assessment programme

- 11.1 Selection of products

- 11.2 Migration of substances with artificial sweat

- 11.3 Analyses of constituents

- 11.4 Health assessment

Preface

The project Survey of chemical substances in headphones and hearing protection aids is a part of the Danish Environmental Protection Agency’s combined efforts related to survey of chemical substances in consumer products.

The purpose of the project was to create an overview over the market for the two product groups, which materials are being used in products of today and propose how a health assessment can be made.

The project was managed by FORCE Technology, with senior project manager Anders Schmidt as project manager and with Erik Bjarnov and Tenna Brandt Nielsen as responsible for the chemical analyses.

1 Summary

As a part of the Danish Environmental Protection Agency’s survey of chemical substances in consumer products, knowledge of which materials and substances can be found in headphones and hearing protection aids is established. The project was conducted in two phases, the first phase being a survey of the market with focus on information from producers and suppliers, supplemented with information from the Internet, while the second phase elaborated these results through a material analysis of selected products and use of knowledge about polymer materials as available from literature and experiences at FORCE Technology. The project results in a general assessment of the potential risks for consumers from using the products in question and an outline of a project which can establish a more precise assessment by using the approach described in the EU Technical Guidance Document for risk assessment of chemicals.

In the first phase of the project about 70 producers of headphones were identified and the number of different products was estimated to be more than 1,000 products. The product group was divided into three sub-groups, i.e. Around-ear, On-ear, and In-ear headphones. The three sub-groups differ significantly in their design, and potentially also in the choice of materials which come into contact with the skin. No special considerations were given to the fact that many headphones today are integrated with a microphone, so-called head-sets, as there is no indication of alternative materials coming in contact with the skin for these products. Based on different statistical sources it is estimated that 500,000-1,000,000 headphones are sold in Denmark each year.

In the first phase of the project 16 suppliers of hearing protection aids were identified. This product group was divided into two sub-groups, i.e. Around-ear and In-ear. The latter group does in the current project not include single-use products, for which a survey has been conducted earlier. The amount of different hearing protection aids is much lower than the amount of headphones, especially for In-ear products where each producer in general only markets one basic product. The amount of sold hearing protection aids to private consumers is crudely estimated to 10,000 per year, while the amount sold for professional use probably is significantly higher.

Searches on the Internet and contacts to producers established a good overview of which materials are commonly used in the two product groups, but only sparse information about which additives are used to give the desired material properties. It is not surprising that this information is not readily available, given the fact that the materials are selected and bought from raw materials suppliers, based on the technical specifications, while it is less important for producers of headphones to know how the properties have been incorporated in the materials. It is, however, noticed that many of the producers answering a questionnaire answer that their products are ROHS-compatible, i.e. they have no or very limited content of certain heavy metals and flame retardants.

In the second phase of the project, FT-IR analysis of 20 products was performed, comprising 14 headphones (6 Around-ear, 4 On-ear and 4 In-ear) and six hearing protection aids (4 Around-ear and 2 In-ear). The main objective of the analysis was to identify the primary materials, while they could only provide information about additives and fillers if these were present in large concentrations. Additives used in small concentrations are thus not identified, nor is the presence of heavy metals.

The following table summarizes the materials which are known from the survey and the analysis to be used in headphones and hearing protection aids.

| Headphones | Hearing protection aids | ||||

| Materials in contact with the ear, identified by analysis | Around-ear | On-ear | In-ear | Around-ear | In-ear |

| Silicone | X | X | X | ||

| PUR, soft (polyurethane) | X | X | X | ||

| PUR, foam | X | ||||

| PUR, lacquer | X | ||||

| ABS (acrylonitrile-butadiene-styrene) | X | ||||

| Polyester (textile) | X | ||||

| PVC, nitrile modified | X | ||||

| PVC with phthalate plasticizer | X | ||||

| Other materials, identified in the survey | |||||

| Leather | X | ||||

| PC (polycarbonate) | X | ||||

| PC/PBT | X | ||||

| Acryl | X | ||||

| EVA (ethylene-vinylacetate) | X | ||||

| PP/EPDM | X | ||||

| Chloroprene-rubber | X | ||||

| Artificial leather | X | ||||

The approach and scope of the project does not establish precise knowledge about which materials are used most frequently, this will require that more answers from producers are received and/or analysis of more products. Based on the available information it seems, however, credible to assume that PUR (polyurethane) is frequently used, both because it is found in a large part of the products examined and because it is known to possess the desired properties with respect to e.g. user comfort and wear resistance. Also silicone is frequently used, especially in In-ear products where its flexibility makes it well-suited for adaption to the geometry of the inner ear. PVC was not identified in the headphones subjected to analysis, but was identified in three out of four hearing protection aids, either with phthalate as plasticiser or modified with nitrile-rubber.

The results of the analyses made in the project were supplemented with an analysis of the chemical content in the components of a head-set (i.e. a headphone with an attached microphone), kindly provided by a manufacturer. This analysis was primarily aimed at identifying and quantifying substances with allergenic properties, but it also provided information about the amount of other substances present in the product, of which some are known to have effects on human health. With respect to the risk of allergy it is concluded by a recognized research institute that allergic reactions cannot be expected from use of the product examined. In the current project, it is furthermore concluded from the analysis that the amounts of identified substances with effects on human health in the product are so small that they most probably do not pose a risk. It is, however, emphasized that other products within the product group may contain other substances – and in larger amounts. Furthermore, it should be recognized that the analysis made for the producer does not allow for a good estimation of the exposure levels. For this purpose, an analysis of the amount of migrating substances is needed.

With the limited knowledge established in the survey and analysis of the products only a very general assessment of the potential risks to human health can be given. In analogy to other surveys of products with similar materials and exposure routes it is, however, concluded that the risk of being exposed to harmful substances in significant amounts seems to be very small. As indicated, the basis for this conclusion is very limited, and more precise conclusions can only be reached by performing a series of analyses giving the information necessary to conduct a risk assessment of the identified substances using the EU Technical Guidance Document (TGD) for risk assessment of chemicals.

As the final activity in the project a suggestion for the content of a follow-up project is outlined, giving the possibility of making the desired risk assessment following the TGD. The suggested analysis programme focuses specifically on skin exposure, since exposure via inhalation or oral ingestion is judged to be negligible or not existing.

It is also suggested that the analyses to be made comprise chemicals and groups of chemicals known from other surveys to have a potential for effects on human health which may come close to a Margin of Safety of 100, e.g. plasticizers, metals, organotin-compounds, and brominated flame retardants. The outlined approach does, however, also allow for identification and quantification of the migration of other chemicals, which may be relevant in a risk assessment. The suggested analysis programme thus gives the possibility of identifying potential risks with respect to human health, but it is emphasized that the product groups being examined are very heterogeneous with respect to materials (and additives), and the results obtained will probably not be very conclusive.

2 Sammenfatning

Som et led i Miljøstyrelsens kortlægning af kemiske stoffer i en række forbrugerprodukter ønskes viden om hvilke stoffer, der indgår i hovedtelefoner og høreværn. Projektet Kortlægning af kemiske stoffer i hovedtelefoner og høreværn er udført i to faser, der henholdsvis omfatter kortlægning af markedet med fokus på indhentning af information fra producenter og leverandører og en beskrivelse, baseret på analyser og erfaringer, af hvilke materialer, der fortrinsvis anvendes til de pågældende produkter og hvilke additiver, der typisk kan tænkes anvendt. Projektet munder ud i en overordnet vurdering af de sundhedsmæssige risici ved brug af produkterne og en beskrivelse af hvilke yderligere analyser, der anbefales for at kunne gennemføre en vurdering efter retningslinjerne i EU’s Technical Guidance Document til risikovurdering af kemiske stoffer.

I projektets første fase blev der ved internetsøgninger fundet omkring 70 producenter af hovedtelefoner, der skønnet producerer væsentlig mere end 1.000 forskellige produkter. Produktgruppen blev inddelt i tre hovedtyper, nemlig ”Around-ear”, ”On-ear” og ”In-ear” hovedtelefoner, der foruden at være forskellige i udformning også kan tænkes at være karakteriseret ved, at det er forskellige materialer, der kommer i kontakt med huden. Der er ved kortlægningen ikke taget specielt hensyn til, at mange hovedtelefoner i dag også har en mikrofon (de såkaldte head-sets), idet der ikke er grund til at antage, at der er tale om, at det er andre materialetyper, der kommer i kontakt med huden. Ud fra forskellige statistiske oplysninger er antallet af solgte hovedtelefoner skønnet til at være i størrelsesordenen 500.000-1.000.000 stk. pr. år.

I den første fase blev der fundet 16 leverandører af høreværn, der blev inddelt i to overordnede typer, ”Around-ear” og ”In-ear”. Sidstnævnte gruppe inkluderer ikke engangs-ørepropper, der er blevet kortlagt tidligere. Antallet af forskellige produkter er væsentligt lavere end for hovedtelefoner, især for ”In-ear” produkter, hvor hver producent generelt kun markedsfører et enkelt produkt. Antallet af solgte høreværn til fritidsbrug er groft skønnet til 10.000 pr. år, mens antallet af høreværn til professionelt brug formodentligt er væsentligt højere.

Internet-søgninger og henvendelser til producenterne gav et godt overblik over hvilke materialer, der anvendes, men kun megen sparsom information om hvilke additiver, der tilsættes for at give præcis de materialeegenskaber, der er ønskede. Det er ikke overraskende, at producenterne ikke umiddelbart kan eller vil levere denne information, idet de fleste råvarer til produktion af plast- og gummibaserede komponenter vælges ud fra deres tekniske specifikationer, mens det er mindre væsentligt at vide i detaljer, hvordan de tekniske egenskaber er indarbejdet i materialerne. Det skal dog bemærkes, at mange producenter oplyser, at deres produkter overholder ROHS-direktivet, der blandt andet forbyder eller begrænser tilstedeværelsen af visse tungmetaller og flammehæmmere.

I projektets anden fase blev der gennemført FT-IR analyser af tyve produkter, 14 hovedtelefoner (6 ”Around-ear”, 4 ”On-ear” og 4 ”In-ear”) og seks høreværn (4 ”Around-ear” og 2 ”In-ear”). Analyserne sigtede først og fremmest på at identificere de primære materialer, mens de kun kan bruges til identifikation af additiver og fyldstoffer, der er til stede i større mængde. Additiver, der anvendes i små mængder, vil derfor ikke blive identificeret ved analysen, ligesom den heller ikke identificerer tilstedeværelsen af tungmetaller.

Den følgende tabel viser hvilke materialer, der på baggrund af producentinformationer og analyser vides at blive anvendt i hovedtelefoner og høreværn.

| Hovedtelefoner | Høreværn | ||||

| Around-ear | On-ear | In-ear | Around-ear | In-ear | |

| Materialer i kontakt med ørerne, fundet ved analyse | |||||

| Silikone | X | X | X | ||

| PUR, blød (polyurethan) | X | X | X | ||

| PUR, skum | X | ||||

| PUR, lak | X | ||||

| ABS (acrylonitril-butadien-styren) | X | ||||

| Polyester (tekstil) | X | ||||

| PVC, nitrilmodificeret | X | ||||

| PVC med ftalatblødgører | X | ||||

| Andre materialer, fundet ved kortlægningen | |||||

| Læder | X | ||||

| PC (polycarbonat) | X | ||||

| PC/PBT | X | ||||

| Akryl | X | ||||

| EVA (ethylen-vinylacetat) | X | ||||

| PP/EPDM | X | ||||

| Chloropren-gummi | X | ||||

| Kunstlæder | X | ||||

Projektets fremgangsmåde giver ikke en sikker viden om hvilke materialer, der er hyppigst anvendt, dertil er antallet af producentsvar og analyseresultater ikke tilstrækkeligt repræsentativt. Det virker dog sandsynligt, at PUR er et foretrukket materiale, både fordi det er fundet i en del produkter, og fordi det har de ønskede tekniske egenskaber med hensyn til brugerkomfort kombineret med (slid)styrke. Også silikone er et ofte anvendt materiale, specielt til In-ear produkter, hvor materialets smidighed gør det velegnet til at tilpasse sig ørets form. PVC blev ikke fundet i de analyserede hovedtelefoner, mens det blev fundet i tre ud af fire ”Around-ear” høreværn, enten blødgjort med ftalat eller modiferet med nitrilgummi og – måske - en uidentificeret blødgører.

Projektets analyser blev suppleret med en analyse af indholdet af kemiske stoffer i materialerne i et head-set (en hovedtelefon med mikrofon), foretaget for en producent. Denne analyse var primært rettet mod at identificere og kvantificere allergifremkaldende stoffer, men den gav også information om mængden af andre stoffer, herunder stoffer med velkendte effekter på sundheden. Med hensyn til risikoen for allergi konkluderes det i en vurdering, foretaget af et anerkendt institut, at der ikke kan forventes allergiske reaktioner ved brug af det pågældende produkt. I det nærværende projekt vurderes det endvidere, at mængden af identificerede stoffer med potentiale for at påvirke sundheden er så lille, at de med stor sandsynlighed ikke udgør en sundhedsmæssig risiko. Det skal dog understreges, at der i produktgrupperne som helhed sandsynligvis forekommer andre stoffer – og i andre mængder – ligesom en analyse af indholdet ikke giver mulighed for en sikker vurdering af eksponeringsniveauet. Dertil kræves en migrationsanalyse.

Med den viden, der er indhentet i projektets kortlægnings- og analysefase, kan der kun gennemføres en meget overordnet vurdering af de sundhedsmæssige risici. Der er draget analogi til andre kortlægningsprojekter, og denne peger på, at risikoen for at blive udsat for stoffer i skadelige mængder er meget lille. Som indikeret ovenfor er videngrundlaget dog mangelfuldt, og en mere sikker konklusion kræver derfor yderligere analyser af udvalgte produkter med en efterfølgende vurdering af fundne stoffer efter EU’s Technical Guidance Document (TGD) for risikovurdering af kemiske stoffer.

Der gives derfor afslutningsvis i rapporten et forslag til et projekt, der gennem analyser af produkter giver mulighed for en vurdering efter TGD. Det foreslåede analyseprogram fokuserer alene på hudeksponering, idet påvirkning via indånding og oral indtagelse af kemiske stoffer vurderes at være negligibel.

Analyserne foreslås primært at omfatte de stoffer og stofgrupper, hvor det på baggrund af tidligere kortlægningsprojekter skønnes, at der kan være et potentiale for en sundhedsmæssig påvirkning, dvs. blødgørere, metaller, organotin-forbindelser og bromerede flammehæmmere. Den skitserede fremgangsmåde giver dog også mulighed for at identificere og kvantificere migration af andre relevante stoffer. Analyseprogrammet giver dermed mulighed for at få en indikation af mulige sundhedsrisici, men det skal understreges, at der er tale om meget heterogene produktgrupper, og at vurderingen derfor sandsynligvis ikke vil kunne give meget håndfaste konklusioner.

3 Introduction

Headphones are used to an increasing extent, among other things as a result of the fact that music and speech today are communicated electronically, e.g. through MP3 players, mobile phones and PC’s. However, at the same time, headphones being used in the traditional way, e.g. in connection with a stereo, are sold. The many application areas have resulted in a significant product development so it is possible to choose products varying from very small In-ear headphones to the traditional headphones sitting on or encircling the ear. A large number of ways of wearing headphones, using different kinds of spring bands, is available.

The use of hearing protection aids is more limited, but the knowledge of the risk of getting impaired hearing is estimated to result in a growing demand. As the purpose of the hearing protection aids is to keep out sound and noise, only two main types are available on the Danish market, Around-ear (the traditional product) and In-ear hearing protection aids. For private use it is assessed that the former type is the most frequently used.

The close contact with the skin on (or in) the ear means that there is a risk of the chemical substances will migrate from the applied materials (mainly plastics) to the skin surface and thus can affect the users’ health. The purpose of the project is to create an overview of the market for the two product groups, which materials are being used in the products of today and propose how to make a more precise assessment of the health risk when using the products.

The project is conducted in two phases:

- In the first phase of the project a survey of the market through Internet searches and contact to producers is completed.

- In the second phase of the project a number of products in the two product groups, 20 in total, are purchased after which an analysis of the applied materials is completed. Based on the knowledge of the applied materials, conclusions of analogy are subsequently drawn to other survey projects where the same materials and the same way of exposure have been assessed with regard to their potential of causing health effects. Finally, a proposal for a further analysis and assessment of the two product groups is made.

4 Description of the product groups

The product groups being examined in the project are in general described as “Headphones” and “Hearing protection aids”. In practice, these overall descriptions cover a wide range of products with large differences in both mode of operation, design and selection of materials.

4.1 Headphones

Regarding headphones there is a differentiation between the following basic subtypes:

”Around-ear” headphones which are the well-known, ”old-fashioned” type where a loudspeaker is contained in a cup which encircles the ear and thus shut out external noise. The cups are kept in place by an elastic spring band over the head. There are only a few variations in the basic appearance but large differences in the choice of materials for the individual components. A number of models are shown in Figure 1.

Figure 1. Around-ear headphones – different models

”On-ear” headphones, where the loudspeaker is protected by pads sitting outside on the ear. The loudspeaker unit which can be of different size is held against the ear in different ways, e.g. by using spring bands over the head, behind the neck or around the ear. Thereby, the headphones become comfortable to use in different situations, e.g. during exercise of sports. Figure 2 shows three different models.

Figure 2. On-ear headphones. From left with a spring band over head, behind the neck and around the ear.

”In-ear” headphones are small loudspeakers which are placed directly in the ear and may be held in place by a spring band over head, around the neck or around the ear. The loudspeakers may be embedded in hard plastic which has a soft layer of foam or rubber on the outside, if necessary, but they can also be embed in a soft plastic which adapts itself to the shape of the ear when the plugs are placed.

Figure 3. In-ear headphones. From left a model with a spring band, a model with soft material which adapts itself to the shape of the auditory canal and a model that is individually adapted.

Alternative products and technologies. During the recent years a significant development within fields of application, product design and technology has taken place. Within the field of application, especially headsets being used in connection with e.g. the use of a PC can be pointed out. Besides one or two loudspeakers (in general of the On-ear type), the headset consists of a microphone which makes it possible for the user to communicate interactively with the outside world, e.g. in connection with IP telephony or when the computer is used for games in a network (Figure 4). Another field of application in rapid development is hand-free mobile telephony where the user via a loudspeaker (generally of the In-ear type) and an external microphone can use a telephone with very little use of the hands.

Within the field of technology it is especially worth pointing at the Bluetooth technology providing that audio signals are transferred to the loudspeakers without used of a cord. On the other hand it is necessary to provide the headphones with a receiver which is in direct connection with the loudspeakers. This receiver can be integrated in Around-ear and On-ear models, without being visible, while with In-ear models it is often necessary to use a spring band around the ear to keep the receiver unit in place (Figure 4).

The mentioned tends of development are not assessed to have any influence on the basic design of the headphones or on the choice of materials for these.

Figure 4. Examples of a headset and a bluetooth receiver with In-ear loudspeaker

4.2 Hearing protection aids

The product group hearing protection aids is somewhat less differentiated than headphones. Thus, there are only two subgroups, Around-ear and In-ear, as an On-ear product will not be able to fulfil the primary function, to lower the external noise to an acceptable level.

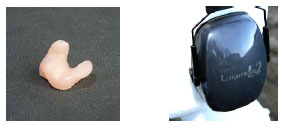

With regard to appearance and materials hearing protection aids look like headphones. Some hearing protection aids have also a sound source so at the same time the user has the possibility of listening to the radio or receiving messages via a wireless system while the external noise is shut out. The two basic types of hearing protection aids are shown in Figure 5.

Figure 5. In-ear and Around-ear hearing protection aids

A subgroup of In-ear hearing protection aids is ear plugs which may be assumed to fulfil the same basic performance as In-ear hearing protection aids but are not adapted to the individual user. This subgroup is mapped in a former survey project from 2003 with two part reports, Consumer project report no. 27 (Surveying of chemical substances in earplugs. Phase 1: Collection of earplugs) and no. 28 (Mapping of chemical substances in earplugs. Phase 2: Analysis of substances), respectively. In these reports basic materials and a number of additives in ear plugs were surveyed based on inquiries to producers, importers and retail trade, followed by an analysis of selected products. The subgroup is not considered further in this survey project but the results will be included where relevant.

4.3 Legislation within the area

According to chief consultant Leif Christensen from the Danish Trade Organisation for Consumer Electronics headphones are covered by the WEEE directive (Waste from Electric and Electronic Equipment, Directive 2002/96/EC) and the RoHS directive (Restriction of the use Of certain Hazardous Substances, Directive 2002/95/EC) (Leif Christensen, personal communication, 17/6-07). The RoHS directive includes a ban on the use of lead, mercury, cadmium, hexavalent chromium, polybrominated diphenyl ethers (”PBDE”, penta-BDE, octa-BDE and deca-BDE) and polybrominated biphenyls in electrical and electronic equipment from 1 July 2006. There are a number of exceptions from the bans in the RoHS directive, e.g. lead in certain types of soldering materials is temporarily permitted. Furthermore, the EU Commission has lifted the ban on deca-BDE for application in polymers (cf. the decision of the Commission dated 13 October 2005). Denmark has taken legal proceedings against the European Court of Justice with the intention to have this decision cancelled.

Products, for which the RoHS directive does not apply, are regulated by the Danish legislation regarding restrictions on the use of the heavy metals lead, mercury and cadmium. This means that these regulations will apply to hearing protection aids. The following legislation is relevant:

- Statutory Order on ban on import and sales of products containing led. Stat. Ord. 1012 of 13.11.2000.

- Statutory Order on ban on import, sales and export of mercury and mercurial products. Stat. Ord. 627 of 01.07.2003.

- Statutory Order on ban on sales, import and production of cadmium-containing products. Stat. Ord. 1199 of 23.12.1992.

Leif Christensen from BFE also assesses that the EuP Directive (Eco-design of Energy-using Products (EuP), Directive 2005/32/EC) apply to wireless headphones with a power supply in the form of a battery.

Products with radio equipment must also keep the requirements in the R&TTE Directive for radio and teleterminal equipment (1999/5/EC).

Finally it can be mentioned that a number of hearing protection aids are equipped with different kinds of radio communication and/or other means of playing music. Therefore they are comprised by the same directives which apply for headphones.

5 Survey of the market for headphones

- 5.1 The market for headphones

- 5.2 Identification of producers of headphones

- 5.3 Information from producers

5.1 The market for headphones

The market for headphones is estimated on a basis of a number of different sources.

5.1.1 Statistics Denmark

Statistics Denmark does not sum up import and export of headphones in units, but only in kilos and kroner. The following information is available in the statistics bank for the product group “Headphones and earphones, also combined with a microphone, except handset for wire telephony” for 2006:

| Headphones | Import (kilo) | Import (1000 kroner) | Export (kilo) | Export (1000 kroner) |

| 436,652 | 116,884 | 167,884 | 84,474 |

The industry’s sales of the product line “8518302000 Headphones and earphones, handset for wire telephony, also combined with a microphone, not for civil flights” amounted in 2006 to 178,736 units at a value of 25.8 million kroner which gives an average unit price of about 144 DKK.

If it is assumed that the same unit price is valid for imported and exported goods the Danish consumption, measured as the difference between import and export, amounts to approx. 225,000 units. However, it is noted that the definitions of products for foreign trade and the industry’s sales of own goods are not identical. It is also noted that many headphones are probably sold as a part of a product packet in which a sound source is included such as e.g. a MP3 player.

5.1.2 Danish Trade Organisation for Consumer Electronics

The Danish Trade Organisation for Consumer Electronics (Brancheforeningen for Forbrugerelektronik) does not assess the sales of headphones as a separate product group in their public statistics (www.bfe.dk). However, it is possible to get an idea of the magnitude of the market by looking at the number of sold products where it can be relevant to use a headphone. For battery-powered (“transportable”) audio products the following information about sales figures in 2006 is available:

- Radio receivers: 20,000

- Cassette radios: 65,000

- DAB radios: 200,000

- Cassette tape recorders: 5,000

- Compact Disc players: 5,000

- MP3 players: 500,000

It is most likely the smaller products such as cassette, CD and MP3 players which are sold with a set of headphones and if each of the sold products within the three product groups has included purchase of headphones too there is the possibility that at least 500,000 headphones have been sold in the Danish market in 2006, solely to transportable audio systems. As transportable audio systems are in question it must be assumed that the main part of the sold products is On-ear or In-ear headphones as Around-ear headphones will normally be regarded as inelegant in this connection.

A number of purchasers of transportable music systems will already have a set of headphones which can be applied to the new product. On the other hand, in cases where a set of headphones is included, the purchasers of music systems will often choose to buy a set of a better quality so that in fact they get two sets but of course only use one of them.

Approximately 125,000 stationary music systems were sold. Headphones will be a natural supplementary purchase for many but if the buyer already has a set of Around-ear headphones of a good quality, he will probably seldom replace these.

Besides headphones for music playing, there are probably also sold some headphones for use with PC’s (IP telephony, computer games in network). Most of these headphones will be in the form of On-ear headsets, including a microphone. Furthermore, In-ear headphones will be sold for use with mobile phones. The information from the Danish Trade Organisation for Consumer Electronics does not give any possibility of estimating how many of these types of headphones are sold annually.

5.1.3 Elretur

Elretur is the Danish system ensuring that all electrical and electronic waste is handled in an environmentally responsible way. The industry has to report the sales of relevant product groups to Elretur. According to Lars Lyng from Elretur, a sale of about 65,000 units per month for the product group headphones is reported which also includes among others clock radios and small transistor radios.

5.1.4 Total estimate of the market of headphones

In total it is estimated that between 500,000 and 1,000,000 sets of headphones are sold annually. It is not possible to give a detailed picture of the distribution on the different types but it is our estimate that the largest number of sold products is to be found within the sub-groups On-ear and In-ear headphones as during the recent years the development has been in the direction of producing “small” products with a satisfactory sound.

5.2 Identification of producers of headphones

The preliminary survey of the market is primarily completed on basis on searches on the Internet. The following web-sites have been visited to identify which producers who have their products for sale on the Danish market, either in physical shops and/or in Internet shops.

www.itbutikken.dk (Internet shop)

www.enavia.com (Internet shop)

www.itonline.dk (Internet shop)

www.elgiganten.dk (El-Giganten)

www.aage.dk (the music house Aage Jensen)

www.avc.dk (Audio Visuelt Centrum)

www.merlin.dk (Merlin)

www.eskilsen.dk (Super Sound)

www.nbradio.dk (Internet shop)

www.hifiklubben.dk (Hi-Fi Klubben)

www.itbutikken.dk (Internet shop)

www.hifishoppen (Internet shop)

www.itonline.dk (Internet shop)

www.fona.dk (Fona)

www.midtdata.dk (Internet shop)

www.computercity.dk (Computer City)

The screening of these web-sites showed that there are at least 70 suppliers of different types of headphones. A quick estimate based on the available prices indicates that the vast majority of products can in general be characterized as being of a rather good quality with a price above 100 DKK. The list of producers is found in Table 1.

Table 1. List of producers of headphones, found through Internet search.

| Acer AKG Altec Lansing Apple Argon Belkin Behringer Beyer Dynamic BOSE Cables Unlimited Canon Canyon Cisco Creative Denon Freecom Fujitsu-Siemens Future Sonics |

GN Netcom Goldring Grado Hama - Iogear HP iPAQ HTC Icemat Jabra Jensen JVC Koss Labtec Lenovo Logitech Maxell Microsoft Motorola |

Nokia Olympus Otek Panasonic Philips Pioneer Plantronics RIM Roland Samson Sandberg Sennheiser Sharkoon Sonomax Sony Sony Ericsson Soundking |

Speed-link Stanton Supreme Swyx Targus Technics TriPort Toshiba Trust Typhoon U.S.Robotics Ultrasone Vic Firth Yamaha Zalman ZIP XtremeMac |

5.3 Information from producers

As the next step in the survey a number of producers’ homepages, chosen at random, were visited with the intension partly to estimate the number of different products, partly to find the key information directly, e.g. which materials gets into contact with the skin when using headphones.

A visit to about 50 homepages showed that most individual producers had a wide selection of products. Several producers had more than 50 different products within the categories ”Around-ear”, ”On-ear” and ”In- ear”. It was not possible to assess unambiguously whether all products are in fact marketed in Denmark but with the distribution of especially Internet shops with large selections it is a realistic estimate that the number of headphone products on the Danish market is in the order of magnitude of 2000.

The visits to the same homepages also showed that as a principal rule a set of technical specifications for each product is available but that they seldom contain any detailed information about the materials used. However, some producers have chosen for selected products to give an general description of the material being in contact with the ear, e.g. artificial leather, PVC, thermoplastic PUR, silicone, velvet, velour or plush.

About 50 producers of headphones were contacted via e-mail or contact forms at their internet page. The purpose of the contact was to get direct information about the used materials and/or a possibility of getting more detailed information from sub-suppliers. As mentioned the intial knowledge-base was very poor and therefore a strategy with following head lines was applied.

Producers giving information about one or more materials were asked for further information about the materials in question. If PVC was mentioned, questions about the use of plasticizers were asked. If artificial leather was mentioned, it was asked whether the plastic component was PVC, PUR or something else and questions about use of other additives were asked. The producers were also asked whether they used other materials which come into contact with the ear and finally, they were asked whether they have had complains from customers about irritation or allergy from the use of headphones.

If there was no information about the use of (specified) materials, it was asked which materials gets into contact with the ear, whether they contained additives and if so, which additives. Also this group of producers was asked whether they had received complains from the customers.

In certain cases, if a producer from one of two groups markets a large number of products, questions about only a few of these were asked. The background for this strategy was that it was assumed that the task of giving a satisfactory answer for all products would be so demanding in terms of resoures that the producer would choose to ignore the request for this very reason.

The results of the Internet searches and requests to producers are reported in the next chapters.

6 Survey of the market for hearing protection aids

6.1 Statistical information

The product group hearing protection aids is not a unique item in surveys from Statistics Denmark which has not been able to point at which classification is being used in practise.

It has not been possible either to identify which branch(es) the producers belong to. From Internet searches it is estimated that the main part of the Around-ear models is imported, among others from Sweden where the producers also produce helmets, visors and other protective equipment. In certain cases it is most probably subsidiary companies of a large concern with a very wide range of products in the market.

The individually adapted In-ear models are produced both in Denmark and abroad. For certain products it takes place in the way that in Denmark an imprint of the shape of the ear is taken and thereafter a set of ear plugs is produced abroad. Also here it might be the case that the hearing protection aids are a part of a large product range which for example could include hearing aids.

There are no requirements to disposal of hearing protection aids unless they contain electronic equipment. Therefore it is not possible to get an indication of the size of the market in this way.

Accordingly, a good estimate of the market for hearing protection aids cannot be given. It is not possible either to differentiate between the two basic types of hearing protection aids, or to distinguish between products for professional use and for leisure use. However, common sense says that the market is substantially smaller than the market for headphones as they are products with a long lifetime being used of a small group of consumers. A very rough guess is that the number of sold hearing protection aids for leisure use does not exceed 10,000 units annually and is thus 1-2% of the market for headphones. The number of hearing protection aids for professional use is assumed to be somewhat higher as it is a legal demand that the employees have to be protected against hearing damaging noise. Here the lifetime of a hearing protection aid of course comes into play and in this connection it should be mentioned that in some cases it is possible to replace parts of a hearing protection aid, e.g. cover and/or ear pads. However, it is not a part of the project to investigate hearing protection aids for professional use.

6.2 Identification of producers of hearing protection aids

Producers and suppliers of hearing protection aids were identified via Internet searches, both in the most simple way by searching for “hearing protection aids” on Google and by searching for “hearing protection aids” on home pages for do-it-yourself markets, tool suppliers, working environment organisations, etc.

Table 2 shows the producers/suppliers which are judged to be relevant on the Danish market. It shall be noted that it was not possible to distinguish between products for private use and professional use so it is assumed that there are not fundamental differences between the products being sold to the two types of users.

Table 2. Products/producers of hearing protection aids on the Danish market

| Producer | Type of hearing protection aids |

| Sonomax | In-ear |

| Hellberg | Around-ear |

| Bilsom | Around-ear In-ear Ear plugs |

| Peltor | Around-ear |

| AKU | In-ear |

| EARFoon | In-ear |

| AudioVox | In-ear |

| Phonak | In-ear |

| 3M | Around-ear Ear plugs |

| Rexton (Elacin) | In-ear |

| Jonsered | Around-ear |

| Optimuff | Around-ear |

| Sordin | Around-ear |

| DeWalt | Around-ear Ear plugs |

| Bulloch | Not stated |

| Passive hearing protective aids | Not stated |

| Profi | Around-ear |

Fourteen of these producers were contacted via e-mail or contact forms on their Internet page. Exceptions were e.g. made for products like Bulloch and “Passive hearing protection aids” which are sold in an multi-product shops, and where it neither through the seller’s homepage nor more detailed searches was possible to find further information about the product or the producer. The purpose of the contact was to get direct information about the materials used and/or a possibility of getting more detailed information from sub-suppliers. As mentioned the initial knowledge base was rather poor and therefore the same strategy as for headphones was used.

Producers giving information about one or more materials were asked for further information about the materials in question. If PVC was mentioned, questions about the use of plasticizers were asked. If artificial leather was mentioned, it was asked whether the plastic component was PVC, PUR or something else and questions about use of other additives were asked. The producers were also asked whether they applied other materials which come into contact with the ear and finally, they were asked whether they have had complains from customers about irritation or allergy from the use of hearing protection aids.

If there was no information about the use of (specified) materials, it was asked which materials gets into contact with the ear, whether they contain additives and if so, which additives. Also this group of producers was asked whether they had received complains from the customers.

Some producers, e.g. Peltor, Bilsom og Sordin, market a large number of products and therefore there was only asked about details for a few selected products. The background for this strategy was that it was assumed that the task of giving a satisfactory answer for all products would demand so considerable resources that the producer would choose to ignore the request for information for this very reason.

The results of the Internet searches and application to producers are reported in the next chapters.

7 Materials in headphones and hearing protection aids

- 7.1 Materials in headphones

- 7.2 Materials in hearing protection aids

- 7.3 Summary – survey of materials

7.1 Materials in headphones

The materials being used in headphones are mapped through Internet searches and via information from the producers.

7.1.1 Materials, found via Internet searches

Most of the information about materials is found via searches on the producers’ homepages on the Internet. Only a very limited part of the available products is described with regard to the materials coming into contact with the ear and in nearly all cases the information concerns the material being used for ear pads, or in which the loudspeakers in In-ear headphones are moulded.

Below the material being identified via the searches are stated, no matter if they appear often or are only found in a single case.

Table 3. Material identification in relation to headphones.

| Material identification | Type of headphone |

| Silicone (incl. “medical grade” and “Hypoallergent”) | In-ear |

| Foam | On-ear |

| Leather-effect | On-ear |

| PVC (also “vinyl”) | On-ear |

| Thermoplastic polyurethane | Around-ear |

| PC (polycarbonate) | On-ear |

| Artificial leather (also “foam-filled artificial leather” | Around-ear |

| Rubber | In-ear |

| Textile (velour, velvet, plush) | Around-ear |

| ”Slow-memory material” | Around-ear |

| Polyester (PET) | Ear cup for On-ear |

| Rubber | Ear hook for On-ear |

| Leather | Around-ear |

Based on the searches it has not been possible to establish an unambiguous connection between the choice of material and the quality/price. Artificial leather (which is not a well-defined material) is together with PVC the material being mentioned most often for Around-ear headphones while textile and leather are only mentioned a few times, all in connection with products which are judged to be “high-end” products of a high quality. “Foam” is assumed to cover foam rubber which is primarily manufactured from polyurethane but it can also be manufactured from PVC.

For In-ear headphones silicone seems to be the dominant choice of material but also “rubber” is mentioned in this connection, however, without a more precise description. However, it must be assumed that In-ear headphones with “hard” ear buds are not manufactured from silicone but from plastic types like (hard) PVC (polyvinylchloride), PC (polycarbonate) or ABS (acrylic onitrile-butadiene-styrene). For many of these, a cover of foamed plastic is included which in the same way as for Around-ear and On-ear headphones will primarily be manufactured from PUR (polyurethane) or PVC.

7.1.2 Information from producers

The inquiries to producers of headphones confirmed that the preferred materials for use in headphones are PVC, polyurethane and silicone for Around-ear and on-ear headphones while the soft material being applied in in-ear headphones is silicone. Which materials are being applied for in-ear with hard ear-buds did not appear from the received answers.

The answers from producers/suppliers only contributed with few details besides information about the primary materials being applied. However, one single producer of head sets and other electronic equipment placed an analysis report of a product at our disposal. From the report and the following communication it appears that the following materials can get into contact with the skin for the product in question:

- EVA (ethylene vinyl acetate) in ear pads

- A mixture of PP (polypropylene) and EPDM (ethylene/propylene dimer), a so-called thermoplastic elastomer, in an ear hook

- ABS (acrylic onitrile-butadiene-styrene), in a fastening spring band

- Soft foam, manufactured from chloroprene rubber for a stabilization spring band

- PC/PBT (polycarbonate/polybutylene terephthalate), for loudspeaker house

A detailed examination of the analysis results is found in section 8.3.

7.1.2.1 Information about toxicology and user-experience

None of the producers of headphones answering to the inquiry had the knowledge that their products had caused allergy or other inconveniences and diseases for the users. It shall be noted that information about this from individual persons cannot be regarded as fully adequate but it has been outside the frames of the project to follow up at producers and suppliers.

An acknowledged institute has assessed the analysis results of the headset being described in general in 7.1.2 and more detailed in section 8.3 with regard to the risk that the materials cause allergy in the users of the headset. In their assessment, the institute points at the following substances as potentially problematic in relation to allergy: cobalt, nickel, chromium and 4-tert-butyl phenol. Based on the low concentrations of the four substances in the materials, the institute concludes that allergic reactions cannot be expected. None of the substances identified in the analysis were regarded as irritants. However, the institute remarks that there might have been other substances in the materials than those being selected for the analyses.

7.2 Materials in hearing protection aids

Mapping of the materials being used in hearing protection aids was attempted through Internet searches and direct inquiries to producers.

7.2.1 Materials, found through Internet searches

Through the Internet searches the following materials were identified for the two types of hearing protection aids.

Table 4. Materials in hearing protection aids

| Around-ear | In-ear |

| PVC (in a bag, not detailed described) | Silicone Medical silicone (approved for implants) Acrylic Acrylic/silicone-mixture |

7.2.2 Producer information

The occurrence of PVC in Around-ear hearing protection aids was confirmed by three of the large producers. One of them also told that two tests for allergenic properties had been made – both were negative. Unfortunately, it has not been possible to get further details about the content of additives in the products in question or about the allergy tests in question. However, another producer provided a list of the requirements to concentrations of substances which their products must comply with in order to be approved by BG Prüfzert which is a German association of test and certifying bodies which primarily deals with working environment. For hearing protection aids the following requirements to constituents are laid down:

Table 5. Requirements in BG Prüfzert for maximum concentrations of certain substances and groups of substances

| Substance/group of substance | Concentration |

| Metals | |

| Arsenic | ≤ 25 mg/kg |

| Lead | ≤ 25 mg/kg |

| Antimony | ≤ 25 mg/kg |

| Tin | ≤ 50 mg/kg |

| Phthalates | |

| Di-(2-ethylhexyl)-phthalate | ≤500 mg/kg |

| Total phthalate Dimethylphthalate, diethylphthalate, di-n-butylphthalate, di-isobutylphthalate, benzylbutylphthalate, di-(2-ethylhexyl) phthalate, di-n-octyl-phthalate, di-iso-nonylphthalate, other phthalates being quantifiable with reference to the applied method of analysis. |

≤ 5000 mg/kg (until 30/6-2008 ≤ 7500 mg/kg) |

| Organisc tin compounds (Total of monobutyl, dibutyl, tributyl, tetrabutyl and dioctyl tin. Shall only be determined if the concentration of tin is larger than 50 mg/kg). |

= 50 mg/kg |

It is outside the frames of the project to complete an assessment of the importance of fulfilling these requirements. However, it is clear that for phthalates it is rather low concentrations that are permitted (0.05% di-(2-ethylhexyle)phthalate and 0.5% total phthalate) as soft PVC often contains more than 30% phthalate.

Likewise the use of silicone and acrylic in in-ear hearing protection aids was confirmed by suppliers. For in-ear hearing protection aids of silicone both raw materials and a “finished” set of hearing protection aids were made available for analyses. A producer of in-ear hearing protection aids of both silicone and acrylic made a set of safety data sheets available for the project. It should be noted that in-ear hearing protection aids of both acrylic and silicone are individually fitted as they are either manufactured through embedment directly in the ear (possible with silicone) or embedment in a mould giving an imprint of the shape of the ear. The safety data sheets describe the following substances which are the basis of classification of the raw materials:

Table 6. Constituents in raw materials for production of hearing protection aids in silicone and acrylic. From the producers’ safety data sheets.

| Hearing protection aids of silicone | Constituent(s) | CAS No. | Concentration |

| Cristobalite | 14464-46-1 | 10-25% | |

| Paraffin waxes and carbon hydride waxes | 8002-74-2 | Working place exposure possible – concentration not stated | |

| Amorphous silica | 07631-86-9 | 25% | |

| Dimethyl, methylhydrogene siloxane copolymer | 68037-59-2 | 10% | |

| Hearing protection aids of acryl | |||

| Methylmethacrylate | 80-62-6 | 50-100% | |

| Ethandiol-1,2,-dimethacrylate | 97-90-5 | 2.5-10% | |

| 2-Benzotriazolyl-4-methylphenol (Tinuvin P) |

2440-22-4 | ≤ 2.5% | |

| N,N-dimetyl-p-toluidine | 99-97-8 | ≤ 2.5% | |

| 1,4-dihydroxybenzene | 123-31-9 | ≤ 0.1 % | |

| Dietylphthalate | 84-66-2 | Working place exposure possible – concentration not stated |

At least one producer states to have a possibility of surface treatment of hearing protection aids of silicone with a lacquer based on toluene (20-60%) and xylene (20-60%).

From another producer of hearing protection aids of silicone a bottle with lubricant is included which can ease the insertion of the hearing protection aids. Among the constituents in this lubricant is phenyl mercury nitrate in concentrations of less than 0.01%. The substance is a preservative.

7.2.2.1 Information about toxicology and user-experience

None of the producers of Around-ear hearing protection aids answering to the inquiry had the knowledge that their products had caused allergy or other inconveniences and diseases for the users. It shall be noted that information about this from individual persons cannot be regarded as fully adequate but it has been outside the frames of the project to follow up at producers and suppliers.

However, a producer of both hearing aids and hearing protection aids informed that their experience with hearing aids in hard acrylic was that about 2% of the users experienced allergenic skin rwactions without stating information about the specific reason for the allergy. To these patients the hearing aids were therefore produced in titanium or another hypoallergenic material. Apparently, the producer in question does not manufacture hearing protection aids in hard acrylic.

As mentioned in 7.2.2 a producer of Around-ear hearing protection aids with a bead (bulge/thickening) of PVC has carried out allergenic tests of their products with a negative result. It has not been possible to get further details.

A producer of In-ear hearing protection aids of silicone has carried through tests of biological reactivity of typical raw materials. The following results are described:

- Systemic toxicity in mice. Intraperitonal og intracutaneous administration in mice caused no larger systemic reaction from the test preparation than from salt water, polyethylene glycol 400 or sesame oil.

- The macroscopic reaction from implantation in the muscles of a rabbit was not significant, compared with an USP negative control plastic.

The tests thus show primarily that there is no biological reaction from contact with silicone.

7.3 Summary – survey of materials

First of all, the completed survey shows that a wide range of materials is applied in headphones. The main part of the materials is synthetic polymers (plastic and rubber) but also a natural material like leather is used. It shall be noted that “textile” in this connection is assumed to be polymer-based, e.g. in the form of nylon or polyester.

For hearing protection aids the survey shows that PVC apparently is the preferred material for Around-ear hearing protection aids while silicone and acrylic are the preferred materials for In-ear hearing protection aids.

8 Analysis of selected products

8.1 Purchase strategy

The preliminary survey of the materials and possible additives which can come into contact with the skin has been supplemented with an analysis of a number of headphones and hearing protection aids, chosen randomly without possibility of determining whether the selection is representative. Within the product group headphones alone, more than 1,000 products are available on the Danish market and the selection of products for analysis took therefore preliminary place with basis in criteria such as the largest suppliers were to be represented, that the three types of headphones (Around-ear, On-ear and In-ear) and two main types of hearing protection aids (Around-ear and In-ear) were to be included, that the surfaces as far as possible were different (e.g. foamed/smooth surface and hard/soft in-ear headphones), and at the same time that the selected products were to be in different price levels.

It shall be noted that the differences in the price do not necessarily reflect differences in the choice of material but rather that there is a better sound quality in the more expensive products. It shall also be noted that no products with a price above approx. 400 DKK were purchased. Thus, some products on the market cost above 2,000 DKK, a price which only to a very limited degree can be assumed to be related to the choice of exclusive materials for contact with the skin but rather to the use of exclusive materials (e.g. gold) for cord and generation of the sound signals.

The relevant characteristics for the purchased products are:

Table 7. General characteristics of the purchased products.

| Product group | Number of products | Number of producers | Prices |

| Around-ear headphones | 6 | 6 | 118, 134, 230, 273, 384, 771 DKK |

| On-ear headphones | 4 | 4 | 20, 189, 384 DKK |

| In-ear headphones | 4 | 4 | 74, 119, 175 DKK |

| Around-ear hearing protection aids | 4 | 4 | 58, 130, 159, 169 DKK |

| In-ear hearing protection aids | 2 | 2 | Free |

The majority of the purchased products (11/14 headphones, 2/6 hearing protection aids) was purchased via the Internet. The primary reason for this was that in this way it was relatively easy to secure that the purchased products were distributed as wanted. For the hearing protection aids, the purchases were spread on two products from do-it-yourself markets, two from the Internet and two products which the producers delivered free of charge to the project, one as a sample, the other being produced on site.

8.2 Analysis results

There were two main targets of the analyses, i.e. to verify the producer information and to complement these. However, in practice it was not possible to verify the producer information as the purchased products were not provided with information about which materials being applied. Exceptions from this were the two In-ear hearing protection aids where both producers clearly tell which materials form the basis of the products.

8.2.1 Analysis method

The IR analyses were completed on a Nicolet Impact 400 FT-IR spectrometer.

Different techniques were applied, dependent on the product. Flat, smooth materials were examined by use of ATR technique. Materials which were not smooth and flat were examined by rubbing a silicon carbide sandpaper against the sample and record the spectrum by DRIFT (diffuse reflectance) with the clean sandpaper as reference.

ATR as well as DRIFT are reflection techniques and the spectra become a little distorted compared to normal transmission spectra.

For identification of plastic types electronic reference libraries (Hummel-Scholl eller Sadtler Know-it-all) were mainly used combined with FORCE Technology’s general experience.

Plasticizers like phthalates are normally applied in large amounts (30%) and will immediately be seen in the spectra. Often these substances will camouflage the spectrum of the basic polymer. Phthalate being present in a few percentages of another ester will normally not be observed. Other additives being applied in 0.1 to a few percentages will normally not be observed at the screening analysis unless they have absorptions in areas where a basic polymer and a possible softener for certain do not absorb.

Fillers with characteristic spectra, e.g. chalk, will be identified at levels of 10-30% while other fillers often cannot be identified for certain.

8.2.2 Analysis results

The results of the analysis of the selected products are shown in Table 8.

Table 8. Identified materials at FTIR analysis.

| Product description | IR result + remarks | IR technique | Product no. |

| Headphones | |||

| Headphone Around ear | Polyurethane (soft) | ATR | 5 |

| Headphone Around-ear | Polyurethane (soft) | ATR | 7 |

| Headphone Around-ear | Polyurethane (soft) | ATR | 14 |

| Headphone/headset Around-ear | Polyurethane (soft) | ATR | 16 |

| Headphone In-ear | Silicone (polydimethyl siloxane) | ATR | 6 |

| Headphone In-ear | Foam part: Polyurethane hard plastic: ABS |

ATR- foam + DRIFT hard part | 11 |

| Headphone In-ear | Polybutadiene-styrene | ATR | 12 |

| Headphone In-ear | ABS | DRIFT | 18 |

| Headphone On-ear | Polyurethane (soft) | ATR | 4 |

| Headphone On-ear | Polyurethane (foam) | ATR | 8 |

| Headphone On-ear | Polyurethane (soft) | ATR | 9 |

| Headphone On-ear | Very black textile material, probably a typical polyester (PET) | ATR | 10 |

| Headphone On-ear | Polyurethane (soft) | ATR | 13 |

| Headphone/headset On-ear | Polyurethane (foam) | ATR | 17 |

| Hearing protection aids | |||

| Hearing protection aids Around ear | Polyurethane (soft) | ATR | 1 |

| Hearing protection aids Around ear | PVC/Nitrile with unidentified plasticizer and/or flame retardant (probably containing phosphorus, similar to product no. 19) | ATR | 2 |

| Hearing protection aids Around-ear | PVC with phthalate plasticizer | ATR | 15 |

| Hearing protection aids Around-ear | PVC/Nitrile with unidentified plasticizer and/or flame retardant (probably containing phosphorus, similar to product no. 2) | ATR | 19 |

| Hearing protection aids In-ear | Silicone (polydimethyl siloxane) | ATR | 3 |

| Hearing protection aids In-ear | Polyurethane, hard (surface/lacquer) | DRIFT | 20 |

In general, the results confirm the information being found in the mapping phase of the project, namely that PUR (polyurethane) in both foamed and soft (artificial leather) quality is often used in parts getting into contact with the ear (On-ear and Around-ear products), that silicone is applied in In-ear products (both headphones and hearing protection aids), and that PVC is a frequently used material in Around-ear hearing protection aids.

Furthermore, the analysis showed some elements which did not appear from the preliminary survey:

- Polyurethane based lacquer is applied for surface treatment of In-ear hearing protection aids in a hard quality, probably acrylic. According to the producer, the lacquer reduces the risk of allergy.

- PVC applied in Around-ear hearing protection aids can be modified with nitrile (acrylonitrile-butadiene rubber) which increases the resistance towards oil and different chemical substances and it also gives an increased flexibility in the material. Thus, nitrile rubber can possibly replace traditional softeners totally or partly.

- For PVC applied in Around-ear hearing protection aids, also traditional plasticizers are used. Unfortunately, the analysis does not give a possibility of a more precise identification of which plasticizer is used.

- In the two In-ear headphones where the hard material was analysed, this was ABS. In the one of the cases the user could choose to put on pads of polyurethane, while the other product did not give this possibility.

- Polybutadiene styrene (a type of rubber) is used as (soft) material in In-ear headphones.

It is emphasized again that the examined products do not necessarily constitute a representative sample of the two product groups. It shall also be emphasized that it was not within the frames of the project to quantify the content of additives in the products; in some cases it was even impossible to determine the substance(s) in question due to interference.

The existing knowledge can be summarized in a few points:

- Which hard materials get into contact with the ear?

- It is known for certain that ABS is used but there are no technological barriers for using materials like polycarbonate (PC), possibly as a copolymer with ABS or PBT. Also, there are no technological barriers for using hard PVC or PP for the purpose.

- Which soft materials get into contact with the ear?

- There is no doubt that PUR is the preferred choice for ear pads for all kinds of headphones, both in the form of foam pads and smooth pads. The analyses do not show whether it is a “pure” PUR material or it is an artificial leather quality where the contact layer is PUR while the substrate layer might be a different plastic or textile (se section 9.3).

- From the detailed analysis of a headset it is known that also foam, based on neoprene rubber, can be used. PVC foam is also a possibility but no information is found showing that this material is used in practice.

- Only a single of the analyzed products had a textile surface in contact with the skin. This material was most probably polyester (PET) which is a well-known and often applied material in all kinds of textiles. As described in section 9, it other synthetic textiles can most probably also be used.

- Which plasticizers are used in PVC – and in which amounts?

- Most probably soft PVC being used in headphones and hearing protection aids is modified in the same way as other soft PVC products. In other words, a wide range of plasticizers (including phthalates) can be used in amounts up to 40%.

- Are flame retardants applied?

- In two Around-ear hearing protection aids, flame retardants of the phosphate type might be applied. It is unknown whether this is the case for other hearing protection aids.

- For none of the identified materials is it possible on basis of the analysis to give a qualified suggestion about type and amount of the additives used. Therefore, typical compositions of frequently used materials given in section 9.

8.3 Analysis of materials in a headset

A producer of headsets and other electronic equipment made an analysis of the materials being a part of one of there headsets available to the project. The headset contains number of components which in one way or another can get into contact with the skin.

- Ear pads in two sizes, both produced from EVA (ethylene vinyl acetate), with contact surface at the external ear.

- Ear hook, produced from a mixture of PP (polypropylene) and EPDM (ethylene/propylene dimer), a so-called thermo plastic elastomer, with a contact surface on the back of the ear.

- Fastening spring band/ear plate, produced from ABS (acrylonitrile-butadiene-styrene), with a contact surface on the external ear.

- Stabilization spring band with soft foam, produced from neoprene rubber, with contact on the scalp.

- Loudspeaker house, produced from PC/PBT (polycarbonate/polybutylene terephthalate), with a (small) contact surface on the external ear.

The headset being analyzed can be varied in different ways. For instance, it is possible to choose between a large and a small ear pad and it can be fastened in three different ways by means of spring bands which either is placed above the scalp or around the ear. The basic model is shown in Figure 6.

Figure 6. The basic design of the analyzed headset.

The analysis results for the materials getting into contact with the skin are shown in Table 9 and Table 10. The analyses was made by an accredited laboratory but the information about analysis methods and detection limits has not been available.

Table 9. Concentration of metals and chemical compounds getting into contact with the skin in the analyzed headset.

| Component | Reciver house w. loudspeaker | Ear pad, small | Earpiece | Ear pad, large | |

| Material | PC/PBT | EVA | ABS | EVA | |

| Chemical compound | Concentration | ||||

| As | mg/kg | <0.1 | <0.6 | <0.1 | <0.2 |

| Cd | mg/kg | 0.17 | <0.04 | 4.14 | <0.01 |

| Co | mg/kg | 0.0173 | 0.64 | 0.298 | 0.33 |

| Cr | mg/kg | 0.12 | 991 | 0.458 | 810 |

| Hg | mg/kg | <0.02 | <0.08 | <0.02 | <0.02 |

| Mn | mg/kg | 0.14 | 0.399 | 0.255 | 0.4 |

| Ni | mg/kg | 0.167 | 0.429 | 3.49 | 0.309 |

| Pb | mg/kg | 0.0875 | <0.3 | 0.35 | 0.101 |

| Zn | mg/kg | 22 | 2.22 | 39.2 | 1.5 |

| Dimethyl phthalate | mg/kg | <1.0 | <1.0 | <1.0 | <1.0 |

| Diethyl phthalate | mg/kg | <1.0 | <1.0 | <1.0 | <1.0 |

| di-n-propyl phthalate | mg/kg | <1.0 | <1.0 | <1.0 | <1.0 |

| di-isobutylephthalate | mg/kg | <1.0 | 18 | <1.0 | 8.5 |

| di-n-butyl phthalate | mg/kg | <1.0 | 20 | <1.0 | 6 |

| di-pentyl phthalate | mg/kg | <1.0 | <1.0 | <1.0 | <1.0 |

| di-n-octylphthalate | mg/kg | <1.0 | <1.0 | <1.0 | <1.0 |

| di-(2-ethylhexyl)phthalate | mg/kg | <1.0 | <1.0 | <1.0 | 4.3 |

| Butylbenzyl phthalate | mg/kg | <1.0 | <1.0 | <1.0 | <1.0 |

| di-cyclohexyl phthalate | mg/kg | <1.0 | 7 | <1.0 | <1.0 |

| di-isononyl phthalate | mg/kg | <10 | 12 | <10 | <10 |

| di-isodecyl phthalate | mg/kg | <10 | <10 | <10 | <10 |

| 4-tert-butylphenol | mg/kg | 0.29 | 0.66 | 0.26 | 0.79 |

| 4-tert-pentylphenol | mg/kg | <0.0050 | 0.11 | <0.0050 | 0.013 |

| 4-tert-octylphenol | mg/kg | <0.0050 | 0.16 | <0.0050 | 0.062 |

| 4-n-nonylphenol | mg/kg | <0.0050 | <0.0050 | <0.0050 | <0.0050 |

| iso-nonylphenol | mg/kg | <0.050 | 53 | <0.050 | 7.5 |

| bisphenol A | mg/kg | 3.2 | 0.9 | 1.9 | 0.13 |

| octylphenol-monoethoxylate | mg/kg | <0.010 | <0.010 | <0.010 | <0.010 |

| octylphenol-diethoxylate | mg/kg | <0.010 | <0.010 | <0.010 | <0.010 |

| octylphenol-triethoxylate | mg/kg | <0.010 | <0.010 | <0.010 | <0.010 |

| octylphenol-tetraethoxylate | mg/kg | <0.010 | <0.010 | <0.010 | <0.010 |

| octylphenol-pentaethoxylate | mg/kg | <0.010 | <0.010 | <0.010 | <0.010 |

| octylphenol-hexaethoxylate | mg/kg | <0.010 | <0.010 | <0.010 | <0.010 |

| nonylphenol-monoethoxylate | mg/kg | <0.10 | <0.10 | <0.10 | 0.85 |

| nonylphenol-diethoxylate | mg/kg | <0.10 | <0.10 | <0.10 | 1.4 |

| nonylphenol-triethoxylate | mg/kg | <0.10 | <0.10 | <0.10 | 5.6 |

| nonylphenol-tetraethoxylate | mg/kg | <0.10 | <0.10 | <0.10 | 11 |

| nonylphenol-pentaethoxylate | mg/kg | <0.10 | <0.10 | <0.10 | 17 |

| nonylphenol-hexaethoxylate | mg/kg | <0.10 | <0.10 | <0.10 | 23 |

Table 10. Concentration of metals and chemical compounds getting into contact with the skin in the analyzed headset (continued).

| Component | T-piece, selv-adhesive foam | Ear spring band, soft | Ear plate with adaptor | |

| Material | Chloroprene | PP/EPDM | ABS | |

| Chemical compound | Concentration | |||

| As | mg/kg | <3 | <0.3 | <0.1 |

| Cd | mg/kg | <0.1 | 0.102 | <0.008 |

| Co | mg/kg | <0.1 | 0.0648 | <0.008 |

| Cr | mg/kg | 1.72 | 0.897 | <0.05 |

| Hg | mg/kg | <0.2 | <0.04 | <0.02 |

| Mn | mg/kg | 1.67 | 9.9 | <0.07 |

| Ni | mg/kg | <0.9 | 8.08 | <0.07 |

| Pb | mg/kg | 2.22 | 0.242 | <0.07 |

| Zn | mg/kg | 13200 | 522 | 18.2 |

| Dimethyl phthalate | mg/kg | <1.0 | <1.0 | |

| Diethyl phthalate | mg/kg | <1.0 | <1.0 | |

| di-n-propyl phthalate | mg/kg | <1.0 | <1.0 | |

| di-isobutylephthalate | mg/kg | 4.1 | 2.4 | |

| di-n-butyl phthalate | mg/kg | 1.3 | <1.0 | |

| di-pentyl phthalate | mg/kg | <1.0 | <1.0 | |

| di-n-octylphthalate | mg/kg | <1.0 | <1.0 | |

| di-(2-ethylhexyl)phthalate | mg/kg | 87 | 5.7 | |

| Butylbenzyl phthalate | mg/kg | <1.0 | <1.0 | |

| di-cyclohexyl phthalate | mg/kg | <1.0 | <1.0 | |

| di-isononyl phthalate | mg/kg | <10 | <10 | |

| di-isodecyl phthalate | mg/kg | <10 | <10 | |

| 4-tert-butylphenol | mg/kg | 0.15 | <0.0050 | |

| 4-tert-pentylphenol | mg/kg | <0.0050 | <0.0050 | |

| 4-tert-octylphenol | mg/kg | <0.0050 | <0.0050 | |

| 4-n-nonylphenol | mg/kg | <0.0050 | <0.0050 | |

| iso-nonylphenol | mg/kg | 0.46 | 1.3 | |

| bisphenol A | mg/kg | <0.050 | 6.4 | |

| octylphenol-monoethoxylate | mg/kg | <0.010 | <0.010 | |

| octylphenol-diethoxylate | mg/kg | <0.010 | <0.010 | |

| octylphenol-triethoxylate | mg/kg | <0.010 | <0.010 | |

| octylphenol-tetraethoxylate | mg/kg | <0.010 | <0.010 | |

| octylphenol-pentaethoxylate | mg/kg | <0.010 | <0.010 | |

| octylphenol-hexaethoxylate | mg/kg | <0.010 | <0.010 | |

| nonylphenol-monoethoxylate | mg/kg | <0.10 | <0.10 | |

| nonylphenol-diethoxylate | mg/kg | <0.10 | <0.10 | |

| nonylphenol-triethoxylate | mg/kg | <0.10 | <0.10 | |

| nonylphenol-tetraethoxylate | mg/kg | <0.10 | <0.10 | |

| nonylphenol-pentaethoxylate | mg/kg | <0.10 | <0.10 | |

| nonylphenol-hexaethoxylate | mg/kg | <0.10 | <0.10 |

Besides the above-mentioned substances, analyses for the following chemical compounds were carried out:

- anisidine

- 4-aminobiphenyl

- benzidine

- 4-chlor-o-toluidine

- 2-naphtylamine

- p-chloraniline

- 4-methoxy-m-phenylendiamine

- 4,4-diaminodiphenylmethane

- 3,3-dichlorobenzidine

- 3,3-dimethoxybenzidine

- 3,3-dimethylbenzidine

- 3,3-dimeth.-4,4-diaminophen.m.

- 4,4-methylene-bis-(2-chl.an.)

- 2-amino-4-nitrotoluen

- 4,4-oxydianiline

- 4,4-thiodianiline

- 4-methyl-1,3phenylendiamine

- 2,4,5-trimethylaniline

- 2-methoxy-5-methylaniline

- toluidine

None of these substances was found in concentration above the detection limit.

8.3.1 Assessment of the analysis results

An acknowledged institute has evaluated the analysis results with regard to the risk of the materials causing allergy in the users of the headset. In their evaluation, the institute points at the following substances as potentially problematic in relation to allergy: cobalt, nickel, chromium and 4-tert-butylphenol. Based on the low concentrations of the four substances in the materials, the institute concludes that no allergenic reactions can be expected. None of the identified substances is considered to be irritants. However, the institute notes that there may have been other substances in the materials than those that have been selected for the analyses.

8.3.2 Comment to analysis results and assessment

Besides an assessment of the risk of allergy, the analysis results give a possibility of pointing out problematic substances in the materials being applied. However, the analyses give only information about the content of substances, not whether they can migrate migration to (artificial) sweat and thus can cause exposure of the users.

The substances in Table 11 are well-known problematic substances. In the table their concentration in the analyzed materials is stated as well as a rough estimate of the total weight of the substance in the components.

Table 11. Known problematic substances and their concentrations in the analyzed headset.

| Component | Material | Substance | Concentration (mg/kg) | Weight of component (g) rough estimate | Total weight of substance (microgram) |

| Earpiece | ABS | Cadmium | 4.14 | 2 | 8 |

| Earpiece | ABS | Lead | 0.35 | 2 | 1 |

| Loudspeaker house | PC/PBT | Bisphenol A | 3.2 | 4 | 13 |

| Ear hook | PP/EPDM | Bisphenol A | 6.4 | 2 | 13 |

| T-piece | Neoprene-rubber | DEHP (di-(2-ethylhexyl)phthalate | 87 | 3 | 260 |

It is emphasized that the above calculation of the total weight of the given substances in the single components is a rough estimate, indicating the order of magnitude.

The total weight of the substances expresses how large the total exposure theoretically can be in the lifetime of the product, probably one year or more. In practise, the exposure is presumably much lesser as in order to be able to affect humans the substances must first be released from the plastic matrix in which they are fixed and then migrate through the skin. Even if the full weight of the substances in question migrates it is assessed that this will not give a risk of effects on the health and therefore it is judged that the concentration of the substances in question is not problematic.

Finally, it shall be mentioned that the analysis is judged to be representative of the materials being applied. However, it cannot in any way be excluded that in similar materials from other raw material suppliers other substances and/or other concentrations of substances can be found. Finally, it is emphasized that the choice of materials for the analyzed headset is not assessed to be particularly representative for the total market for headphones and hearing protection aids, but that the choice still reflects some of the possibilities which are available for a producer.

9 Material descriptions

- 9.1 PVC (polyvinyl chloride)

- 9.2 PUR (polyurethane)

- 9.3 Artificial leather

- 9.4 Silicone

- 9.5 Textiles

- 9.6 ABS

- 9.7 Rubber and thermoplastic elastomers

In the following sections a short, general description is given of the materials which are identified in the survey phase and in the analyses, and which additives that are typically used in manufacturing. It shall be emphasized that most of the descriptions are generic, i.e. that they deal with the material in general and not specifically in relation to their use in headphones and hearing protection aids. It shall also be emphasized that in the survey of earplugs (Karbæk (2003), Pors and Fuhlendorff (2003)), other, potentially problematic substances are identified; these substances are not addressed in the following sections. This emphasizes that it is difficult/impossible to give an unambiguous assessment of which materials/substances that potentially can affect the users’ health.

The material descriptions below of PVC and PUR are primarily based on Schmidt (2006), supplemented in relation to artificial leather with Zürrig & Kruse (2005) and Hioki (without year).

9.1 PVC (polyvinyl chloride)

PVC is basically a stiff homopolymer. In practise, PVC will always be modified to achieve the desired properties of the product. In the production of PVC a wide range of additives can be used and it is often the PVC manufacturing company which makes its own compound by adding the necessary substances and substance mixtures to the basic polymer.

PVC is compounded with plasticizers, stabilizers, fillers and other additives, dependent on the wanted properties.