Survey of Chemical Substances in Consumer Products, No. 100, 2008

Mapping, emissions and environmental and health assessment of chemical substances in artificial turf

Contents

2 Artificial turf pitches – Materials and chemical substances

5 Procurement of sample material

- 6.1 Analysis methods and analysis programme

- 6.2 Results of screening analyses

- 6.3 Results of leaching tests

- 6.4 Discussion of results

- 6.5 Selection of substances for health and environmental assessment

- 8.1 Zinc and its salts

- 8.2 6PPD

- 8.3 Dicyclohexylamine

- 8.4 Diisobutyl phthalate

- 8.5 Nonylphenol

- 8.6 2,4-di-tert-butylphenol

- 8.7 Diethyl phthalate

- 8.8 Bis(2,2,6,6-tetramethyl-4-piperidyl)sebacate

- 8.9 Estimate of effect of discharged substances

9 Abbreviations used in the environmental and health assessments

10 Abbreviations used in the material descriptions and for chemical substances/substance groups

Preface

The “Mapping, emissions and environmental and health assessment of chemical substances in artificial turf” project was carried out between April 2007 and the end of October 2007.

This report describes the results of the project, including mapping of products on the market, materials included in artificial turf pitches, chemical analyses and exposure scenarios as well as health and environmental assessments.

The project was carried out by the Danish Technological Institute with Dr Nils H. Nilsson as project manager and Dr Bjørn Malmgren-Hansen responsible for the health and environmental assessments. Mr Uffe Sognstrup Thomsen contributed with quality assurance of health and environmental assessments.

The monitoring group for the project consisted of:

Frank Jensen Danish Environmental Protection Agency

Dorte Lerche Danish Environmental Protection Agency

Nils H. Nilsson Danish Technological Institute

The project was financed by the Danish Environmental Protection Agency.

Summary and conclusions

In recent years, it has become increasingly popular to use artificial turf as a substitute for natural turf.

Artificial turf is primarily used for football pitches, but it is also becoming increasingly popular for golf greens, school playgrounds and playgrounds in general.

There are a number of advantages in using artificial turf rather than natural turf: The pitches are more hard-wearing and easier to maintain than natural turf pitches, the football season can be extended whatever the weather, and the pitches can be laid in places where it is difficult to get grass to grow. Artificial turf pitches can be used indoors as well as outdoors.

The pitches that have become especially popular are the third-generation pitches. They are characterised by having turf with longer straws (approx. 50-70 mm versus approx. 30 mm previously) and by the pitch infill consisting of a layer of silica sand at the bottom of the loom and a rubber granule layer at the top. The top 20 mm are not filled. Previously, the infill on football pitches was gravel.

The pitches can be laid directly on a smoothed gravel layer, but many pitches are laid with a shock-absorbing pad between the gravel and the artificial turf.

The Danish Football Association, DBU (DBU, 2005) has described the requirements concerning the football functional properties. These requirements were determined by UEFA and FIFA.

Over the past three years, there have been discussions about the possible health and environmental problems associated with the use of artificial turf pitches. This debate arose on the background of Norwegian studies, in particular. A Swedish report published by the Swedish Chemicals Agency (Kemikalieinspektionen) in 2006 supported the concern that the use of artificial turf pitches could have an adverse effect on health and the environment. These concerns relate to both the health risk to the users of artificial turf pitches and to the leaching of chemical substances into the soil and water.

Especially the use of old car tyres in the form of granules has been debated in the Norwegian studies and the Swedish report. It has in several cases been the practice in Denmark, in connection with invitations for tender, to exclude the use of car tyres following from the Norwegian studies and the Swedish report. This has resulted in e.g. grey industrial rubber being used as an alternative.

Against this background, the Danish Environmental Protection Agency has initiated this study of artificial turf pitches, focusing on Danish conditions.

100-120 tonnes of rubber granules are used per pitch as elastic infill in the pitches, unless an elastic pad is used for the base, so the quantities are rather significant.

The study has shown that today (August 2007), 45 artificial turf football pitches have been laid in Denmark. All but one are outdoor pitches. Following 22 interviews with suppliers, municipalities and the Danish Football Association (DBU), there is reason to assume that many more pitches will be laid in the coming years. This is partly due to the excellent technical playing properties of the third-generation pitches, and partly due to the fact that the artificial turf pitches can actually be used for playing sports all 365 days a year.

In order to use the pitches all year, however, it is necessary to salt the pitches during the winter months in order to keep them free of frost and snow. This is one of the aspects that received focus in this study in relation to environmental impacts, as this issue has not previously been investigated in foreign studies, and there is an expectation that using salt impacts the leaching of chemical substances to soil and water, depending on the volume and type of salt (acid or alkaline).

In addition to the Norwegian studies and the Swedish report, a number of results have been published from the Netherlands, Switzerland and France.

The French study was very comprehensive, both as regards the analysis parameters measured and the number of tests. The tests were conducted over a period of one year and covered both the health and environmental aspects of using rubber granules as infill in the pitches.

The conclusion of the French study is that there is no reason for concern in connection with the use of granulated car tyres as infill, neither based on a health nor an environmental assessment. The assessment is based on the low measured values for the emission of substances in relation to the scenarios set up, on which the conclusion is based.

Leaching of chemicals from the artificial turf pitches was studied using a special recovery technique – a so-called lysimeter test. The same applies for a study recently concluded in Switzerland. In lysimeter tests, it is possible to closely approximate “real life” exposure under well-defined test parameters. The lysimeters are constructed in such a way that rainwater or artificial water can be recovered for analysis following passage through the materials and support layers which make up the artificial turf pitches (gravel, elastic pad, artificial turf mat, sand and elastic infill).

The Swiss study included monitoring the sum parameters DOC (dissolved organic carbon), the sum of dissolved organic nitrogen compounds as well as ammonium nitrogen, nitrate nitrogen and nitrite nitrogen. The study furthermore included monitoring the organic substances aniline, alkylated phenylene diamines, benzothiazole, cyclohexylamine, 16 PAHs and the element zinc, as these substances form part of infill based on rubber from car tyres.

After one year of monitoring in Switzerland, the amount of leached substances in almost all tests had dropped to a concentration lower than the detection limit of 0.2 µg/l.

During the study period, no increases of zinc in the drainage water were detected.

One of the conclusions of the Swiss study is that the substances existing on the surface of rubber granules are leached off by rainwater after a short period of time, and there are therefore no reasons for environmental concerns about the use of rubber granules as an infill material.

However, studies on the long-term effects (several years) are lacking.

The Dutch study indicates that there may be increased zinc leaching as a result of ageing of the rubber, which would make zinc more susceptible to leaching. According to one scenario, Dutch threshold values would be exceeded after 11 years (Building Materials Decree (2,100 mg/m²/year)) and after 20 years (Decree on Soil Quality (3,600 mg/m²/year)), respectively. The scenario assumes that the infill is entirely replaced after 10 years of use. If the rubber ages faster than assumed, the threshold values will be exceeded after only 3-4 years. The environmental impact of zinc was assessed at 0.08% of the total zinc impact in the Netherlands, but with an estimated impact of 0.5% if the number of artificial turf pitches is increased from the current 370 to 2,500.

The results from the foreign studies all conclude that on the basis of the measured concentrations of substances that are hazardous to health, there are no health risks in connection with inhalation, neither indoors nor outdoors.

Against this background, and against the background of self-obtained results in connection with preliminary studies under this project in the form of GC/MS headspace analyses conducted on a wide range of infill and artificial turf mat samples, it was decided not to focus on health scenarios in connection with inhalation. In addition, it should be noted that the Danish third-generation pitches are all outdoors, contrary to Norwegian pitches, in particular.

The intention of this study was to supply new information about the health and environmental aspects of the increasing use of artificial turf pitches.

However, as all existing studies show that there are no problems in relation to PAH emissions, this project has not monitored for PAH.

Unlike the foreign studies, however, a larger number of different infill materials and artificial turf mats have been included in this project in order to obtain a better basis of comparison between the different types. The infill materials include granulated tyres, coated tyre granules, thermoplastic elastomers (TPE) with different tinting and, as a new product, coir fibres. All in all, 16 types of infill materials were obtained, eight types of artificial turf mats and two elastic pads. Here, it is important to remember that the term granulated car tyres covers an inhomogeneous mixture, as the infill material could originate from many different types of car tyres.

Furthermore, laboratory studies have been carried out which provide information about leaching of substances from the infill materials, the turf mats and a recycled rubber-based pad as a result of the pitches being salted in winter, as this aspect had not previously been studied. The studies have included road salt in the form of sodium chloride, which is the cheapest de-icing salt, or calcium chloride, which is used in the event of heavy frost. As regards the salt concentration, the leaching tests were based on the recommendations of the Danish Football Association (DBU).

The monitoring included a wide range of organic substances which derive from either the infill or from the artificial turf mats themselves. In particular, there was emphasis on measuring for organic substances which are found in the different tyres as well as their degradation products. Also, particular focus was given to zinc, phthalates and nonylphenols as a consequence of the results from the foreign studies.

Results

A wide range of environmentally harmful substances were found in the contact water (migration medium) from leaching tests on infill, artificial turf and pad, and also a number of substances that are harmful to human health.

For coir infill and “green industrial rubber” infill, substances which have a negative impact on health or the environment were not found in the solvent extract from the materials. However, leaching tests have not been conducted on these to types of infill. It should be emphasised that in one sample of EPDM rubber infill, a content of organic substances was detected (degradation products from peroxide, used in connection with the vulcanisation of the rubber). Therefore, it cannot be excluded that the substances might cause environmental problems, as leaching tests with EPDM rubber infill showed discharge of the substances into the water

Based on the dichloromethane extracts of grey and green industrial rubber, it can be concluded that these were significantly differing types of rubber, even though both infills are labelled industrial rubber by the supplier.

Environmentally harmful substances found in concentrations well above the detection threshold in the contact water are shown in Table 0.1.

Table 0.1 Environmentally harmful substances found in significant concentrations in the contact water in relation to possible health and environmental impacts.

| Substance | Infill | Artificial turf |

| Zinc | X | |

| Diethylphthalate (DEP) | X | X |

| Dibutylphthalate (DBP) | X | X |

| Benzylbutylphthalate (BBP) | X | X |

| Diisobutylphthalate (DIBP) | X | X |

| Dicyclohexylphthalate (DCHP) | X | |

| Diethylhexylphthalate (DEHP) | X | X |

| Nonylphenol | X | |

| Bis-(2,2,6,6-tetramethyl-4-piperidinyl)sebacate | X | |

| Cyclohexanamine, N-cyclohexyl- | X | |

| Phenol, 2,4-bis(1,1-dimethylethyl)- | X | |

| Cyclohexanamine | X |

The zinc leaching measured in this study was of the same magnitude as that found in foreign studies. The leaching of phthalates and nonylphenols, however, was higher in this study.

On the basis of the foreign studies, it was assessed that the leaching conditions from a football pitch differ significantly from the conditions in the leaching tests conducted in the laboratory in this study. Therefore, it cannot be concluded on the basis of the laboratory leaching tests alone whether the substances are an environmental risk under practical conditions. This is due to the fact that during laboratory tests, a better contact is created between the fixed material and the contact liquid than is the case in real life on artificial turf pitches as the result of the weather (e.g. rain). An example is that the sample is placed in the simulated rainwater and shaken for 24 hours before the water is analysed. This should be viewed as an absolutely worst case scenario and would therefore overestimate the actual leaching.

The results from leaching in calcium chloride-based contact liquid (simulated salting) showed a significant drop in the amount of leached phthalates as well as significant changes in the concentration of other substances (both higher and lower values). This is due to the fact that commercially available calcium chloride is highly alkaline due to the calcium hydroxide content. An alkaline environment causes hydrolysis reactions which affect a wide range of organic substances, including phthalates. No significant changes in the zinc leaching were detected as a function of the pH and/or ion strength of the contact liquid, regardless of salt type.

Furthermore, leaching tests have shown the same level of zinc in contact water in new infill as in the same infill after approx. two years of use.

Health assessment

Four representative substances were selected for the health assessment:

benzothiazole, dicyclohexylamine, cyclohexanamine and dibutyl phthalate. These substances are present in high concentrations in contact water from the leaching tests and are representative of the harmful substances emitted from the products.

On the basis of the results from foreign exposure studies and own analyses, it was decided to focus exclusively on exposure via skin contact and oral uptake from particles swallowed.

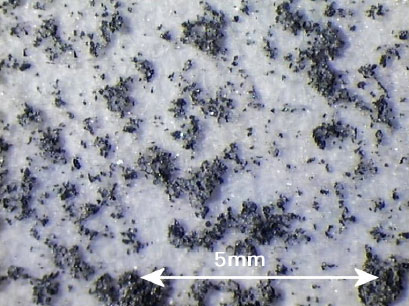

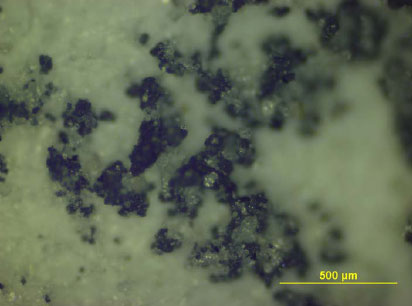

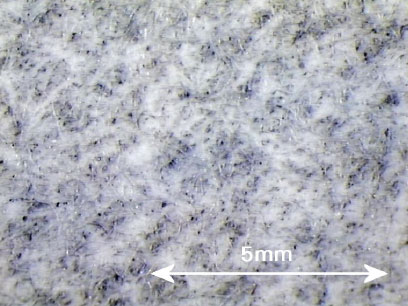

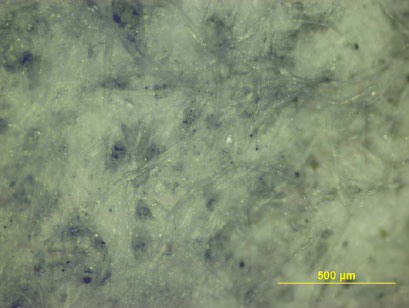

Microscopy of the dust particles from leaching tests has shown a particle size for the finest particles in the order of 10-50 µm, whereas the majority of the particles are approx. 2 mm. With a high content of fine particles, the leaching of health and environmentally harmful substances may increase due to the larger contact area, and the risk of inhalable flying dust is also increased. However, as mentioned, the amount of fine dust in the products is limited. In the assessments of the results, no health risks were found in connection with exposure to the substances, with the exception of a possible allergenic risk for sensitive individuals to benzothiazole and the amines.

Environmental assessment

The substance concentrations in the contact water from the leaching tests were assessed in relation to possible spillover of drainage water to nearby watercourses. It was assessed that there is an environmental risk from a number of the substances found if the drainage water reaches concentrations on a level with those found in the contact water.

It should be emphasised that – as mentioned above – the actual concentrations of chemical substances in the drainage water from third-generation pitches are probably significantly lower than those measured in the laboratory as a consequence of a less efficient natural leaching, because it was assessed that the contact with water is not as efficient as in the laboratory tests.

For some substances, however, the calculations include very large calculated water concentrations in relation to the estimated no-effect concentration (in excess of 100 times), and thus it cannot be ruled out that there may be an environmental risk with the leaching of these substances.

Furthermore, substances were detected, such as peroxide cross-linking chemicals or degradation products thereof, from EPDM infill. These substances were present in very high concentrations in contact water, but there is no data available on environmental risks. The zinc leaching from EPDM infill, however, is significantly lower than from car tyre infill (SBR rubber).

The results from the laboratory tests in this study show that a number of environmentally harmful substances can be leached from elastic infill as well as from artificial turf with a possible environmental risk in the event of drainage water spilling over into nearby watercourses. However, on the basis of the foreign lysimeter tests and pilot studies showing significantly lower leaching than in laboratory tests, it was assessed that measurements of the substance concentrations under real conditions on football pitches are necessary in order to assess the risk. Therefore, this study found no reason to question the conclusions of the elaborate Swiss, French and Dutch studies that rubber granules from car tyres pose no major environmental risk. Here, it should be noted that the Dutch results regarding zinc leaching are not found in this or the French and Swiss studies. On the other hand, it should also be emphasised that these are only short-term studies, and the effect of ageing of rubber granules etc. is therefore unknown.

However, a more recent Dutch study published in the spring of 2008 concludes that over a period of 10-15 years, zinc is not leached in concentrations that constitute any environmental problem. Continued monitoring for zinc in the Swiss study still shows no sign of increased zinc leaching as a result of rubber ageing (U. Hofstra, 2008, Edwin Müller, 2008).

When setting up a monitoring programme for the drainage water, it is possible, when selecting analysis parameters, to benefit from the results from this study and from the foreign studies mentioned in the report. For instance, measurements for PAHs can be excluded, and measurements for phthalates can be added.

1 Introduction

1.1 Artificial turf pitches are popular

In recent years, it has become increasingly popular to use artificial turf as a substitute for natural turf.

Artificial turf is becoming increasingly popular for golf greens, school playgrounds and playgrounds in general, but it is primarily used for football pitches.

The international football associations UEFA and FIFA thus accept the use of artificial turf pitches for football if the pitches meet the requirements for functional properties in relation to football (FIFA, 2006).

Figure 1.1 Outdoor artificial turf football pitch

There are several advantages in using artificial turf rather than natural turf. Artificial turf pitches are more hard-wearing and easier to maintain than natural turf pitches. The football season can be extended whatever for the weather, and the pitches can be laid in places where it is difficult to get grass to grow.

Artificial turf pitches are used indoors as well as outdoors. In Denmark, however, artificial turf pitches are almost exclusively used outdoors.

According to the Danish Football Association (DBU) (A. Johansen, 2007), there are four indoor pitches in Denmark. However, only two of these are third-generation pitches. One is a three-quarter pitch in Brøndby; the other is a newly installed pitch in Ikast. The infill material in Ikast is polyethylene-coated sand, contrary to the traditional third-generation pitches where the infill is sand plus an elastic granulate.

The sports arenas Valby-hallen and Ballerup-hallen also feature indoor pitches, but according to DBU, these are of the second-generation type (without elastic infill).

According to DBU, there are no immediate plans to establish further indoor pitches in Denmark.

In most cases by far, artificial turf consists of plastic fibres attached to a polypropylene or polyester carpet loom (see Fejl! Henvisningskilde ikke fundet.). The polyester mesh is coated with an adhesive suspension which is cured in an oven. One supplier mentions that a styrene butadiene latex is used for the adhesive.

Figure 1.2 Mesh for artificial turf, front and back

The fibre height is typically 3-6 cm. A mixture of sand and an elastic granulate is used in order to secure the artificial turf pitches. The sand is used because of its weight, and the purpose of the elastic granulate is to provide springiness.

Pitches using an elastic granulate as the springy part of the concept are called third-generation artificial turf pitches. Third-generation artificial turf pitches have been developed from 1990 to the present day.

A fourth-generation artificial turf pitch is also on the way, where an additional foamed elastic sublayer immediately below the turf structure is introduced. This makes it possible to reduce the volume of rubber granules per square metre, thus making it possible to use alternative elastic infill materials, such as ethylene propylene diene rubber (EPDM), at a competitive price (T.V. Pedersen, 2007). However, it does not give better playing properties compared to the other pitch types.

The concept of fourth-generation artificial turf pitches has not yet been defined by DBU.

In Magglingen, Switzerland, an artificial turf pitch has been laid on a pad without the use of elastic infill. The grass (PE) is held upright using polyamide support fibres.

Figure 1.3 PE grass with polyamide support fibres

However, according to the information available, this pitch does not meet the applicable FIFA requirements for playing properties. The requirements were made with a view to the properties of pitches with elastic infill, which was state of the art at that time.

Since then, and practically without exception, rubber granules from obsolete car tyres (styrene butadiene rubber (SBR)) have been used as the springy part of the infill material. This is due to the fact that, so far, tyre granules have been by far the cheapest infill material. Tyre granules are available as a raw material in ample supply, as approx, 60% of all rubber (approx. 20 million tonnes per year) is used to produce tyres which are discarded sooner or later. For a third-generation football pitch, approx. 100-120 tonnes of rubber granules are used. However, this volume can be reduced by installing an elastic pad under the mat on the reverse of the artificial turf.

Coated infill types also exist. The coating is typically polyurethane with an added colourant (e.g. green).

Tyres contain a number of chemical substances which are cause for health and environmental concerns, which means that rubber from discarded car tyres should be used with care.

This aspect, combined with the fact that the use of artificial turf has become increasingly popular, has resulted in several countries launching research projects designed to investigate the health and environmental impacts from artificial turf pitches (T. Källquist, 2005; C. Dye et al., 2006; T.S.W. Plesser, 2004; T. Sanner, 2006; Swedish Chemicals Agency (Kemikalieinspektionen), 2006; H.J. Kolitzus, 2006; Verschoor, 2007; M. van Bruggen et al., 2006; U. Hofstra, 2007; R. Moretto, 2007). The results of these projects will be briefly reviewed in chapter 3. Chapter 2 reviews the chemistry relating to the materials which are used to make artificial turf pitches.

Chapter 4 describes the mapping of the use of artificial turf pitches in Denmark. Chapter 5 follows, containing descriptions of sample materials procured in the form of artificial turf mats, infill materials and pads.

Chapters 6 and 7 deal with analysis methods and analysis programme and the health assessment, respectively. The report concludes with chapter 8 with an environmental assessment.

2 Artificial turf pitches – Materials and chemical substances

2.1 Possible constituents

For artificial turf pitches, plastic fibres made of polyethylene (PE), polypropylene (PP) and polyamide (PA) are used (The Grass Yarn & Tufters Forum, 2006). These are attached to a perforated mesh of PP or polyester. This is coated with a latex-based adhesive which is subsequently cured. Rubber granules or thermoplastic polymers are used for the elastic infill, but there is also a product on the market which is based on natural fibres. Sand is used to weigh down the grass. The sand could be coated with an elastomer or PE. Additionally, an elastic sublayer is usually included under the artificial turf. This could typically be a coarse rubber fraction from tyres glued together using polyurethane, but other types are also available in the market.

Below follows a brief description of the substances which can be expected to leach from artificial turf pitches on the basis of the chemical structure of the plastic or rubber type used as well as the additive chemicals used to stabilise the molecular chains against degradation due to weather.

For rubber, degradation products may be present as a result of vulcanisation. The volume and the chemical structure are often unpredictable, because they depend on the vulcanisation system used, and the time and temperature.

With wear and tear, rubber dust may be produced, which can be a source of exposure via skin or respiratory passages.

2.1.1 Chemical substances in the artificial turf mats

The existing literature (The Grass Yarn & Tufters Forum, 2006) states that the artificial turf fibres are primarily produced from polyethylene (PE) or polypropylene (PP), but that nylon (polyamide) is also an option. The same source indicates that PE is used exclusively for football pitches.

Antioxidants are usually added to PE and PP in order to improve weather resistance, which is otherwise already good due to the saturated carbon chain structure. The antioxidants are typically organic phenolic structures with a relatively high molecular weight in order to prevent evaporation. Organic phosphites are usually added as auxiliaries, as this provides a synergistic protective effect against oxidative degradation.

Furthermore, UV stabilisers are added to protect against light degradation. Typical UV stabilisers are of the HALS type (Hindered Amine Light Stabilisers). Some UV stabilisers are contain zinc, e.g. Tinuvin 494 from Ciba Speciality Chemicals.

The fibres are coloured green. Some of the green colourants can be based on metallic complexes (copper), or they can be of the azo colourant type, of which some, e.g. yellow, are known to be potentially carcinogenic. The green colour is produced by mixing yellow and blue colours.

Previous studies carried out by the Danish Technological Institute show that volatile short-chain hydrocarbons often degas from PE as well as PP. It was thus expected beforehand that the artificial turf mats would degas volatile, short-chain hydrocarbons in a similar manner. It was expected that there might also be softeners in the latex adhesive used, e.g. in the form of phthalates.

2.1.2 Chemical substances in the elastic infill

According to the existing literature (The Grass Yarn & Tufters Forum, 2006), the overwhelming majority of the artificial turf pitches laid are based on recycled, granulated tyres (98%).

Information exists (T.V. Pedersen, 2007) that one of the disadvantages of using the granules is the black colour, and that, especially in wet weather, the rubber easily sticks to clothes, footwear and skin.

Another disadvantage is the smell of rubber, which is most predominant in hot weather, however. The smell can be suppressed by watering.

There are alternative options when choosing materials. You can either use coated granules from tyres in order to reduce the migration of substances from the granules, or you can use EPDM rubber granules and thermoplastic elastomers (TPE) or mixed granules. Coated sand is also mentioned as an option. Infill material based on natural fibres also exists. Finally, an infill material is marketed under the designation industrial rubber. According to the supplier, this is surplus rubber from the production of window piping.

The problem with several of the alternatives to granulated car tyres is that the price level of the infill materials is increasing.

According to (The Grass Yarn & Tufters Forum, 2006), coated tyre granules are four times as expensive as the base raw material.

According to the same reference, if you switch to EPDM or TPE, the price increases further to eight to 14 times, respectively, compared to natural rubber granules (The Grass Yarn & Tufters Forum, 2006). Since the price of an artificial turf football pitch using tyre granules is approx. DKK 5 million, substituting the tyre granules results in a considerably increased installation price. This is assuming that the figures are correct, which is questionable on the basis of information from suppliers to the Danish market.

Information is thus provided that some of the alternative infill materials are only two-to-four times more expensive than pure tyre granules. From one supplier to the Danish market, the following approximate prices were stated for 120 tonnes of infill in the types of infill used for the pitches: Granulated car tyres: DKK 180,000, coated granules from car tyres: DKK 500,000, EPDM, TPE and coir: DKK 850,000. If the density of EPDM compared to granulated car tyres is taken into consideration, the price of EPDM increases to DKK 1,100,000.

Information was provided, however (T.V. Pedersen, 2007), that by using fourth-generation structures with foamed cross-linked polyethylene (PEX) pads it is possible to achieve competitive prices for alternative infill materials made from EPDM rubber.

2.1.2.1 Granulated tyres

In connection with the “Emission and health evaluation of PAHs and aromatic amines in car tyres” project (Danish Environmental Protection Agency, Kortlægning nr. 54, 2005), detailed descriptions were given of the raw rubber types forming part of the recipes for passenger cars tyres as well as for truck tyres.

The raw rubber types are natural rubber (NR), styrene butadiene rubber (SBR) and butadiene rubber (BR). SBR rubber is the main component in tyre treads.

In addition to carbon black (soot), aromatic oils, zinc oxide, stearic acid, antioxidants and antiozonants as well as sulphur and accelerators form part of the recipe. The accelerators contain nitrogen and sulphur and, when heated, can emit carbon disulphide and split off amines, of which several can be nitrosamine-forming. In addition to zinc, rubber granules made from discarded car tyres can emit copper and chromium from the steel cord used to reinforce the tyres. The accelerators used are typically based on benzothiazole, which can be split off during vulcanisation. The antiozonants are predominantly 6-PPD [N(1,3-di-methyl-butyl)N´phenyl-p-phenylene diamine], but other p-phenylene diamine-based antiozonants, e.g. IPPD (N´-isopropyl-N´phenyl-p-phenylene diamine) are also used. The Norwegian studies (C. Dye et al., 2005; C. Dye et al., 2006; T.S.W. Plesser, 2004; T. Sanner, 2006) also observed emission of phthalates as well as long-chain alkylphenols from the rubber granules. The phthalates could originate from adhesives and the alkylphenols from reactive resins used in the vulcanisation of butyl rubber types (J.S. Dick, 2001). Butyl rubber forms part of tyres as an airtight layer.

2.1.2.2 EPDM rubber

EPDM rubber consists of carbon chains constructed from the monomers ethylene and propylene and a diene component, typically norbornene, built in as a side chain. The advantage of this polymeric structure is great weather resistance, making it unnecessary to add antiozonants to EPDM rubber. The volume of antioxidants can also be reduced. EPDM can be subjected to either peroxide or sulphur vulcanisation. In both cases, zinc oxide may be a constituent, but in greater volume in the sulphur vulcanisation. In sulphur vulcanisation, the usual accelerators based on nitrogen and sulphur are used. For the peroxide vulcanised types, organic peroxides are used, typically dicumyl peroxide which splits off acetophenone during vulcanisation. Other types may split off tert-butyl alcohol. The softeners used for EPDM are predominantly naphthenic oils with a relatively low aromatic content. Triallyl cyanurate is used in peroxide vulcanised EPDM rubber as a cross-linking regulator.

2.1.2.3 Industrial rubber

Municipalities and football clubs that do not want tyre granules specify instead that they want infill in the form of industrial rubber.

In principle, industrial rubber is all rubber, as all technical rubber products are produced industrially. One supplier calls industrial rubber a surplus product from the rubber industry, originating from window piping production.

Based on the supplier’s information alone, it is not possible to assess the chemical composition of the granules.

2.1.2.4 TPE

TPE is an abbreviation of thermoplastic elastomers. SEBS is a typical thermoplastic elastomer based on a Styrene Ethylene Butadiene Styrene structure. TPE is distinct from rubber in that it is not vulcanised. Instead, a mesh structure is formed by the styrene segments forming crystalline domains. Since the chain structure is saturated, SEBS is characterised by good weather resistance, as was described for EPDM rubber. The emission of chemical substances from SEBS is predicted to be limited, because no vulcanisation chemicals are used as is the case for rubber.

2.1.2.5 Natural fibre-based infill

A single supplier offers a natural fibre-based infill material. This is based on coir fibres.

3 Foreign studies

Detailed studies of artificial turf pitches have primarily been conducted in Norway (T. Källquist, 2005; C. Dye et al., 2006; T.S.W. Plesser, 2004; T. Sanner, 2006), but ongoing as well as concluded studies with comprehensive monitoring programmes for a number of environmental parameters are also being conducted in Sweden (Swedish Chemicals Agency (Kemikalieinspektionen), 2006), the Netherlands (Verschoor, 2007; M. van Bruggen et al., 2006; U. Hofstra, 2007; R. Moretto, 2007), Switzerland (E. Müller, 2007; H.J. Kolitzus, 2006) and France (R. Moretto, 2007). The Swedish report is primarily based on information from other sources.

3.1.1 Norwegian studies

Four Norwegian reports are available which, in different respects, assess health and environmental risks as a consequence of the laying and use of artificial turf pitches in Norway.

Two of the studies were conducted at the behest of the Norwegian Pollution Control Agency (Statens Forurensningstilsyn (SFT)) (T. Källquist, 2005; C. Dye et al., 2006). One was conducted for the Norwegian football association (T. Sanner, 2006), and the final one was conducted by Byggforsk (T.S.W. Plesser et al., 2004).

SINTEF Building and Infrastructure (Byggforsk) (T.S.W. Plesser et al., 2004) mentioned above has published its final report on potential health and environmental impacts associated with artificial turf pitches for the Norwegian football association in September 2004.

The Byggforsk study included three infill rubber granule types based on recycled rubber (all three presumably from tyres) and an EPDM rubber granule product (presumably not recycled). In addition, two artificial turf fibre types based on PE and PE/PP copolymer were used. One type was split fibre, the other monofibre. Split fibres are produced by slitting PE film. Monofibres are produced by each fibre being extruded separately. This should provide better long-term wear resistance.

The study analysed for total contents of arsenic, lead, cadmium, copper, chromium, mercury, PCB, PAH, phthalates and phenols in the materials. Furthermore, leaching tests and degassing tests were conducted.

The risk assessment was performed in a simplified version, as the total content of environmentally harmful substances in the source materials was compared to the SFT’s normative values for most sensitive area use. In Norway “most sensitive area use” means areas intended for housing, gardens, kindergartens, schools etc.

The contact water from the leaching tests of rubber granules from recycled rubber contained zinc, PAHs, phthalates and phenols. The amount of zinc places the contact water in the SFT class V (very polluted water), but it is lower than the zinc content allowed in the Canadian Environmental Quality Guidelines for drinking water.

The amount of antracene, fluoroanthene, pyrene, phthalates and nonylphenols is higher than that allowed in the Canadian Environmental Quality Guidelines.

According to the authors, it will require a more detailed risk analysis and further tests to determine whether there is a real risk of harm to the environment and health from the substances measured in the contact water.

The rubber granules from the recycled rubber emit a number of alkylated gaseous benzenes. In one of the tests, degassing of trichloromethane was detected, and in another cis-1,2-dichloroethene. The report recommends performing actual measurements on an artificial turf pitch in order to determine whether the emission is problematic.[1]

With the exception of the of chromium and zinc content, the EPDM granules contained smaller amounts of environmentally dangerous substances than the granules from recycled rubber. EPDM also emitted smaller amounts of volatile substances.

In the actual artificial turf fibres, copper and zinc were detected. In both cases, the leaching of zinc from these types of artificial turf to demineralised water are above the SFT’s threshold values for zinc in drinking water (class V).

In one artificial fibre type, contents of octylphenol and nonylphenol were detected. Furthermore, DEHP was detected in both types of artificial fibre. One sample also contained DMP and DINP.

The Norwegian Institute for Water Research (Norsk Institutt for vannforskning) (T. Källquist, 2005) has assessed the environmental risk on the basis of studies of environmentally harmful substances existing in materials used when laying artificial turf pitches, and their potential as regards leaching via rainwater.

The risk was assessed on the basis of the results in the Byggforsk report described above, and by calculating the PEC/PNEC ratio, where:

PEC is “Predicted Environmental Concentration”, and PNEC is “Predicted No Effect Concentration”, i.e. the highest concentration which will not result in harmful impacts on the environment.

The assessment follows the standard procedures used in risk assessment of chemicals in the EU.

The scenario on which the assessment is based is an artificial turf pitch with an area of 7,200 m², annual precipitation of 800 mm and drainage into a nearby stream. Naturally, the flow rate in the stream will have an impact on the dilution ratio. This was set to be a factor of 10.

The amount of artificial fibre turf and rubber granules for a pitch with the area mentioned was set at 5,760 kg and 129,600 kg, respectively.

It is a supposition for the calculations that the concentrations found in the contact water are equilibrium concentrations, i.e. independent of the water/material volume ratio.

The calculations showed that there is a possibility of environmental impacts for small recipients receiving surface water from artificial turf pitches.

The substances contributing the most are zinc and alkylphenols (in particular octylphenol).

The concentration of leached substances is expected to diminish, but over many years.

The amounts leached into the water are modest, and according to the report, any environmental impacts will therefore only be local.

In order to obtain a better basis for evaluating the environmental impacts of the artificial turf pitches, the authors believe that measurements should be conducted directly on drains from laid artificial turf pitches. The measurements should include toxicity tests.

The Norwegian Institute for Air Research (Norsk Institutt for Luftforskning (NILU)) conducted air pollution measurements in three indoor artificial turf sports halls in 2005 (C. Dye et al., 2006).

The measurements were conducted for artificial turf pitches with newly laid rubber granules (SBR tyres), with rubber granules laid one year previously (SBR tyres) and for an artificial turf pitch with thermoplastic elastomer (TPE) infill.

The measuring programme included analysing flying dust PM10 and PM2.5 for the proportion of rubber, and the concentration of vulcanisation compounds, anti-ageing agents, phthalates and tar substances (PAHs). Furthermore, measurements were made for volatile organic compounds (VOC) and polycyclic aromatic hydrocarbons (PAHs) in the air phase.

Measurements were made for the total sum of volatile organic compounds (TVOC) in the three sports halls, as well as for a wide range of specific volatile compounds.

The study lists concentrations for benzothiazole, toluene, 4-methyl-2-pentanone, diethyl phthalate (DEP), diisobutyl phthalate (DIBP) and dibutyl phthalate (DBP) as well as TVOC. TVOC was in the interval 136 µg/m³ to 716 µg/m³. The largest concentrations were found for toluene: 15-85 µg/m³ and benzothiazole: 3-16 µg/m³.

The study concludes that TPE provides a lower TVOC than the granules based on SBR from used tyres.

The content of organic materials in the flying dust was considerable in all three sports halls. Typically, these are PAHs, phthalates, semi-volatile organic compounds, benzothiazoles and aromatic amines.

In the report (T. Sanner, 2006) prepared by the Norwegian Institute of Public Health (Nasjonalt folkehelseinstitutt) and the Radium Hospital (Radiumhospitalet), the health risk for football players was assessed.

The assessment used nine exposure scenarios, including inhalation via the respiratory passages, skin exposure and oral intake.

The inhalation scenarios are based on the highest detected VOC level of approx. 716 µg/m³, even though VOC in the other two sports halls monitored was 2.5-3 times lower.

On the basis of the scenarios, the report concludes that, based on the exposures calculated from the use of indoor halls with artificial turf, and where granulated rubber from discarded car tyres is used, there is no reason to assume that these will lead to an increased health risk. However, certain reservations are made regarding the development of asthma/airway allergies, in which area the existing knowledge is limited. This applies in particular to latex allergenes.

It is an open question whether these latex allergenes can occur in dust from artificial turf pitches with infill based on discarded car tyres.

For several of the detected substances in the sports hall air, the toxicological knowledge is limited. However, the concentrations of the substances are very low, and for this reason they are not expected to pose any health risk.

According to the report, the exposure amounts for benzene and PAHs pose no health risks.

According to the authors, it is deemed necessary to replace the current SBR rubber granule infill in the sports halls based on the existing knowledge on health effects, but it is recommended that when adding infill, recycled SBR from tyres should not be used, as there is a possible risk of inducing latex allergy.

3.1.2 Swedish status report

In 2006, the Swedish Chemicals Agency (Kemikalieinspektionen) published a status report “Artificial turf from a chemical perspective” (Konstgræs ur et kemikalieperspektiv) (Kemikalieinspektionen, 2006) concerning health and environmental problems in connection with the use of artificial turf.

The report focuses exclusively on artificial turf football pitches with an infill made from recycled car tyres.

According to the report from June 2006, Sweden has approx. 150 artificial turf football pitches laid on infill made from rubber granules from recycled tyres.

Most pitches are for outdoor use, but indoor pitches also exist.

In the Stockholm area alone, there are apparently plans for 30 new artificial turf pitches.

It is assessed that approx. 90% of the pitches will be based on infill from recycled tyres.

To a large extent, the report is based on the Norwegian studies, the results of which are reviewed.

There are also references to a few individual measurements in artificial turf halls in Sweden.

Measurements and calculations showed a very low content of benzo(a)pyrene, approx. 10,000 times lower than the threshold set by the Swedish working environment authority.

The report reviews European guidelines, including the German provisional standard DIN 18035-7:2002.

The report finally concludes that granules from recycled rubber originating from car tyres should not be used as infill when laying new artificial turf pitches. The reason for this is an environmental objective set by the Swedish parliament, determining that materials containing particularly dangerous substances should not be used.

The other conclusions are very close to the corresponding Norwegian recommendations and with the very same arguments.

3.1.3 Dutch studies

Three comprehensive Dutch studies are available (A.J. Verschoor, 2007; M. van Bruggen et al., 2006; U. Hofstra, 2007):

- RIVM report 601774001, on the leaching of zinc from rubber infill in artificial turf pitches (A.J. Verschoor, 2007)

- RIVM report 609300001, on nitrosamines in rubber granules (M. van Bruggen)

- INTRON report on health and environmental aspects of infill rubber granules from recycled car tyres (in Dutch, but with English summary) (U. Hofstra, 2007).

The report on zinc leaching concludes that the leaching of zinc from SBR infill will show an increasing trend as a consequence of the ageing of the rubber. It is assessed that the zinc impact from infill will be 800 mg/m²/year. In the Dutch Building Materials Decree, an acceptable zinc impact is set at 2,100 mg/m²/100 years. According to the authors, this value is thus exceeded already after approx. three years. It is stated that the zinc impact locally would be approx. 20 times higher than from agriculture (slurry manure and pesticides).

The report concludes that further studies on zinc leaching could reduce the experimental uncertainty which underlies the risk assessment.

It is suggested that studies be made on the ageing of different types of rubber and on the effect of the ageing on the leaching of zinc and other substances which may migrate from rubber.

Furthermore, field measurements are suggested for artificial turf pitches with infill rubber of different ages and qualities. Bioassays of the drainage water are recommended to determine the impact of the mixture of substances emitted from the infill material. Finally, mini field tests (lysimeter) are recommended – e.g. on 1 m³ samples.

An INTRON report (U. Hofstra, 2007) concludes that leaching of zinc from rubber granules from used car tyres is considered to be the most serious source of environmental pollution from outdoor artificial turf pitches. It states that the Dutch threshold values for zinc emissions are expected to be exceeded within a 3-20 years utilisation phase.

A conference presentation (N. Salzmann, 2006) concludes that the amount of airborne nitrosamines (N-nitrosodimethylamine) measured on a pitch[2] is higher than the health threshold. The assessment is based on a scenario in which the pitch is used for football three times a week for a duration of two hours. According to the paper, the threshold was exceeded after eight years. There were no further details about the experimental parameters and the monitoring.

In another very comprehensive study (P.C.J.M. Janssen, 2006), the concentration of nitrosamines was measured in the air above four artificial turf football pitches in Arnhem at a height of 30-100 cm. It was concluded that nitrosamines could not be detected in the air. Laboratory measurements detected nitrosamines in small concentrations in the actual infill material.

The overall conclusion of this study was that nitrosamines are not a health problem (contrary to the conclusion above).

As regards health risks in the form of skin contact, inhalation or oral intake, it is concluded that there is no significant risk for football players as a consequence of infill in artificial turf pitches based on rubber granules from used car tyres.

3.1.4 Swiss study

In Bern, Switzerland, a project was launched in May 2006 involving at least one year of monitoring of the leaching of selected chemical substances and common parameters (H.J. Kolitzus, 2006).

The study was based on the use of lysimeters, which are used for e.g. studies of the uptake of nutrients by plants. The lysimeters are constructed from reinforced polyester tubes with a diameter of 1 m and a height of 1.5 m. The tubes contain an automatic water collection system. This enables collection of the total amount of rainwater from an artificial turf surface. The collected water is subsequently analysed.

Figure 3.1 Lysimeter test, Bern, Switzerland

Collection takes place in containers connected to the concrete bottoms of the lysimeters.

For the test series, ten different types of surface were selected, which are used in connection with the laying of artificial turf pitches.

EPDM and SBR rubber are included as infill material, as is sand and different types of support layers, e.g. bitumen-based or as recycled SBR rubber granules on top of a free mineral support layer.

A preliminary conclusion has been made on the basis of test results from May-September 2006.

Emissions of aromatic amine complexes and benzothiazoles were detected in the concentration range 10-300 µg/l, but no significant discharge of PAHs to the drainage water was detected, and this was also the case for recycled SBR. The detection limit for the individual PAHs was at approx. 0.02 µg/l.

The preliminary conclusions of the completed study, prepared in German by E. Müller, the professional expert associated with the study, were sent to the Danish Technological Institute by email on 29 August 2007.

In addition, the results were summarised (E. Müller, 2007) in September 2007 at a meeting arranged by the German BASPO (Bundesamt für Sport (Federal Office for Sport) in Magglingen, Switzerland.

Below is the English translation (from Danish) of the most important information and conclusions from the study.

Figure 3.2 Detail from lysimeter tests in Bern, Switzerland

Table 3.1 Studied artificial turf materials in the Swiss lysimeter tests

| Artificial turf pitch | Artificial turf pitch with EPDM-granules (peroxide vulcanised) and silica sand on elastic pad Artificial turf with rubber granules from car tyres and silica sand. Artificial turf pitch with EPDM granules (sulphur vulcanised) and quarts on elastic pad Artificial turf pitch without infill |

| Elastic pad | Water permeability one-layer EPDM pad Water permeability multilayer coated plastic Waterproof sandwich coating |

| 0-Sample (for investigating the natural background contribution for the measured analysis parameters) | Gravel with smoothed gravel layer Gravel with smoothed gravel layer and bitumen layer Elastic pad based on granulated car tyres |

The study included leaching of the following chemical substances and common parameters:

- Aniline

- Alkylated phenylene diamines

- Benzothiazole

- 16 PAHs

- Zinc

- Ammonium nitrogen

- Nitrate nitrogen

- Nitrite nitrogen

- Sum of dissolved organic nitrogen compounds

- Sum of dissolved organic compounds (DOC)

Additional determination of the zinc content of the different rubber granules was made, as well as thermal analyses and leaching tests in order to characterise the different granules.

It was concluded that with modern analytical measuring equipment, it is possible to detect even the smallest traces of organic substances. The substances are washed from the surface by rainwater after a relatively short period of time. At the end of the one-year period, the concentrations of leached substances were in almost all cases smaller than the detection limit of 0.2 µl per litre. In leaching tests in the laboratory, the leaching profile from the artificial turf pitches was confirmed in the lysimeter tests.

It was also established that the substances leached from rubber granule infills and rubber pads are the same substances which are drained from roads as a result of rubber wear particles from the car tyres, and which are discharged from municipal treatment plants.

During the one-year study period, there was no increase in the leached amount of zinc ions to the aquatic environment. All tests showed the same low content of PAHs on a level with the contents of the O samples. No health or environmentally harmful PAHs could be detected in the water from the tests.

The preliminary conclusion is as follows:

- The rubber granules and elastic pads used for artificial turf pitches are insoluble in water. All granules, newly manufactured as well as granules from crushed car tyres, leave traces of chemical substances which can be detected in the rainwater collected.

- The organic substances present on the surface of the rubber granules will be leached by the rainwater within a short period of time.

- With the knowledge we have today, there is no foundation for any claim about environmental problems concerning the leaching of undesirable chemical substances from artificial turf pitches and elastic layers (infill and pad). However, no long-term studies are available (covering several years).

- The preparation of testing methods and norms should be discouraged as the necessary basis for their development is not available.

3.1.5 French study

A French study is available (R. Moretto, 2007) which was prepared for ADEME, Aliapur and Fieldturf Tarkett i 2007. Aliapur is a French company involved in granulating tyres in France. In 2005, the company’s production of rubber granules from tyres corresponded to a volume of 283,000 tonnes of tyres (85% of tyre refuse in the French market). Fieldturf Tarkett is one of the major international players within third-generation artificial turf. Annually, the company lays 650 major sports pitches, of which 100 were laid in France in 2006. ADEME is the French ministry of the environment, which has supported the fact-finding project. The practical implementation took place in a French research network (EEDEMS).

The study was initiated on the basis of, among other things, the information (the Norwegian reports and the Swedish report) which was presented on the possible health and environmental problems in using recycled tyres as infill for artificial turf pitches.

The reports also formed the basis for implementing some of the studies referred to previously, e.g. those from the Netherlands and Switzerland.

The study included environmental impacts on water as well as an assessment of the health risks associated with gaseous emissions.

As regards materials, the studies included artificial fibres from Fieldturf Tarkett combined with granules from used tyres, virgin EPDM and TPE-based infill.

3.1.5.1 Discharge of substances into water

In the studies involving the discharge of substances into water, infill sand was included as well as the joinings and the polyurethane adhesive used to join the artificial turf pitches.

17.5 kg of sand and 15 kg of elastic infill were used in the experiments.

The experiments were performed as in situ experiments and pilot scenario experiments.

For the in situ experiments, a lysimeter system was applied. The system was based on a stainless steel tray with a surface area of 2 m² and a height of 10 cm at one end and 5 cm at the other. The tray was placed in an artificial turf football pitch. The rainwater percolate was collected in the bottom of the tray and pumped into analysis receptacles.

The monitoring period was 11 months.

For the pilot studies, rectangular aluminium tanks with a length of 2.5 m and a width of 1 m were used. Bottoms and sides were based on waterproof geomembranes. The percolate was collected via drainage pipes at the bottom of the structure.

The test setup was indoors, and rain simulation was carried out by using nozzles which dosed an amount of water corresponding to the average precipitation in a number of European capitals (800 mm of rain annually).

As with the in situ experiments, the monitoring period was 11 months.

The analysis programme in connection with the two types of test setups was extensive. For instance, 42 chemical/physical parameters were monitored:

Total cyanide, phenolic index, total hydrocarbons (THC), 16 PAHs, TOC, Al, As, Ba, Cd, Co, Cr, Cu, Hg, Mo, Ni, Pb, Sb, Se, Sn, Zn, fluorides, nitrates, ammonium, chlorides and sulphates as well as pH and conductivity.

Furthermore, ecotoxicological characterisation of the percolates was carried out through inhibition tests with Daphnia magna in accordance with EN ISO 6341 and with Pseudokirchneriella subcapitata in accordance with EN ISO 28692 (inhibition of algae).

The volume of water dosed in the four pilot studies was 800 l/m²/15 kg of granulate, and the percolate collected was 580 l/m². This is taken to indicate that approx. 27-30% of the water evaporates into the atmosphere.

The conclusion from the two types of experiments is that the concentrations of the substances and common parameters measured are compatible with French and European guidelines, but the authors have not provided detailed specification of the guidelines to which reference is made.

The conclusion from the ecotoxicity tests is that the percolate from third-generation artificial turf pitches, regardless of the type of infill, does not demonstrate a negative impact on the environment.

3.1.5.2 Emission of volatile substances

In the studies looking at the emission of volatile substances, the following materials were tested: artificial turf with green artificial fibres including a band of white fibres, polyurethane adhesive, sand and three different infill granulates. EPDM, SBR from used car tyres and TPE were used as granulates.

As in the studies for discharge into water, 17.5 kg of sand and 15 kg of elastic infill were used in the experiments.

For a sample of 0.15 m², which was actually tested, this corresponded to 2.625 kg of sand and 2.25 kg of granulate.

The test was performed on sample material placed in steel trays measuring 0.78 m x 0.19 m at 23°C and a relative humidity of 50% ± 5%. The test was conducted in accordance with prEn ISO 16000-9: Indoor air – Part 9: Determination of the emission of volatile organic compounds from building products and furnishing – Emission test chamber method.

A specific ventilation speed of q = 1.25 m3/m²/h was used.

The tests measured for VOC and aldehydes.

The conclusion from the studies were:

- The emission from artificial turf alone is very low (TVOC = 8.3 µg/m³ over a period of 28 days) compared to parquet flooring.

- The emission from artificial turf with granulate from used tyres as infill is low (TVOC = 134 µg/m³ over a period of 28 days).

- The emission from artificial turf with TPE granulate as infill is also low (TVOC = 118 µg/m³ over a period of 28 days).

- The emission from artificial turf with EPDM as infill is higher (TVOC =490 µg/m³ over a period of 28 days).

On the basis of a worst case scenario (for indoor use, the starting point is a hall with an artificial turf surface of 1,800 m² and a volume of 20,000 m³), it was concluded that:

- On the basis of the concentration of VOC and aldehyde emitted to the indoor air, there should be no concerns in connection with outdoor use of artificial turf pitches seen from a health perspective.

- On the same background of measurements, neither should there be any concerns in connection with indoor use, seen from a health perspective. This applies to professional athletes, amateur athletes, children and adults as well as the people installing the pitches.

There exists, however, a risk for the people installing the indoor artificial turf pitches if this takes place in badly ventilated halls over a period of more than five years. In such cases, air replacement of two volumes per hour is recommended.

It should be added that the conclusions regarding the impact as a result of the discharge of substances into water were made on a short-term and medium-term basis.

Furthermore, it was emphasised that there is a comparable impact from the infill material, regardless whether this is based on virgin TPE and EPDM or on granulate from used car tyres.

The conclusion is interesting when compared to the conclusions of the Norwegian, Swedish and Dutch studies. On the basis of the French study, there are thus no grounds for phasing out the use of granulated car tyres (SBR), and in this study, EPDM emits more VOC than SBR. It should be noted, however, that there are many different recipes for EPDM, so a particularly oily type may have been chosen for the comparison.

3.2 Overall conclusion of the foreign studies and strategy for this study

Overall, it can be concluded that more or less all foreign studies conclude that there are no health problems for users of artificial turf pitches, neither indoors or outdoors.

On the other hand, the foreign studies do not reach a common conclusion as regards recommendations/preferences regarding the use of different infill materials for artificial turf pitches and their environmental impact. Here, the results of lysimeter studies carried out in France and Switzerland indicate that, in practice, there should be no problems in using granulated car tyres as infill in the pitches, compared to other infill types. A Dutch study concludes that increased zinc leaching may occur from granulated car tyres as a result of ageing of the rubber. This is the only report making this hypothesis. In Norway, the risk of an environmental impact as a result of leaching of chemical substances from granulated tyres is assessed to be small, with the exception of particularly sensitive areas. The Swedish status report discourages the use of granulated car tyres with reference to restrictions in Swedish law. No lysimeter tests have been carried out in Sweden unlike in France and Switzerland, but the conclusion was largely based on the Norwegian studies.

The foreign studies include a limited number of artificial turf mats and infill types. For instance, coir infill and grey industrial rubber have not been reviewed. This Danish study has therefore emphasised collecting as many different types of artificial turf mats and infills as possible in order to perform a mutual comparison of the materials used on the market as well as the chemistry associated therewith.

In the assessment of the environmental impact on soil and groundwater from the pitches, the Danish Environmental Protection Agency has also been interested in mapping and reviewing the significance of using salt on the artificial turf pitches, as well as the use of any herbicides. This interest is related to the weather in Denmark as well as the fact that all Danish artificial turf pitches, with the exception of two, are outdoors. One Danish municipality has used large quantities of salt, and a hypothesis was therefore made that larger volumes of salt in the form of sodium chloride, as a result of the change in ion strength, could increase the leaching of certain substances to the water and soil. Calcium chloride or magnesium chloride are also used for salting, and it is therefore also possible that divalent positive ions (Ca++ and Mg++) could have an impact on the leaching of zinc from the artificial turf pitches containing zinc.

The strategy of this project has therefore been to provide comparisons between the artificial turf mats and infill materials available in Denmark, with the main emphasis being on the environmental impact on the soil and water from outdoor artificial turf pitches. At the same time, the focus on the health assessment of the impact on users in connection with contact and inhalation was reduced during the project period as a consequence of the results which were published during the course of the project, and which, more or less without exception, conclude that there are no health problems associated with the use of artificial turf pitches, regardless of the infill type.

4 Mapping

4.1 Method

Manufacturers and suppliers of rubber granules and artificial turf fields have been contacted to identify the market for third-generation artificial turf pitches and the expectations for new pitches in the coming years.

The knowledge gathering has included information about the actual structure of artificial turf pitches and the materials used for establishing the pitches.

At the request of the Danish Environmental Protection Agency, information has been gathered about any use of chemicals in connection with winter salting of the pitches and any use of herbicides as part of pitch maintenance.

The mapping of conditions specific for Denmark has been based on interviews conducted via questionnaires (see Appendix 1).

The mapping has also included a review and summary of publicly available reports or lectures on environmental studies. The results summary of this literature study is reviewed in chapter 3.

The mapping in relation to Danish conditions has furthermore been based on inquiries made to and interviews with Dansk Boldspil-Union (DBU), football clubs and municipalities with a view to obtaining an overview of artificial turf pitches already laid and expectations for new turf pitches being laid in the coming years.

4.2 Interview

As mentioned above, a questionnaire has been used (Appendix 1). The questionnaire has been forwarded to a couple of large players within manufacture, supply and establishment of artificial turf pitches in Denmark in June 2007. Subsequently, the questionnaire has been used as a basis for telephone interviews, among other things for registering information acquired in connection with questions about local conditions for artificial turf pitches such as maintenance, salting etc. A total of 14 municipalities, football clubs and sports associations have been asked questions and suppliers of artificial turf pitches approved by DBU and suppliers of elastic infill materials have been contacted.

The information acquired in connection with the mapping, including the literature study of international experiences, form the basis of the conclusions drawn with respect to:

- The extent of artificial turf pitches in Denmark

- Materials used

- Chemical constituents significant for the survey

- Exposure scenarios

4.2.1 Artificial turf pitches in Denmark

4.2.1.1 Number of artificial turf pitches and forecast for new pitches

According to information obtained from a seminar held at the Faculty of Life Sciences, Forest & Landscape, University of Copenhagen, on 28 March 2007, 45 full-scale third-generation artificial turf pitches are currently established in Denmark.

This corresponds with information obtained from suppliers of artificial turf pitches approved by DBU on the basis of a FIFA certificate.

This also corresponds with DBU’s website (visited on 15 August 2007) which lists 45 third-generation pitches.

However, the indoor pitch in Ikast mentioned in the introduction is not included in DBU’s list. The reason for this could be that it is not a third-generation artificial turf pitch according to DBU’s definition as the infill is polyethylene-coated (PE) sand. PE is not an elastic material in itself, but it is flexible even at minus degrees due to the extremely low glass transition temperature (÷120°C).

It has been stated that 25 new artificial turf pitches have been put out for tender this year (2007), which means that the municipal mergers in Denmark apparently have not temporarily postponed the propensity to invest in the area due to a restructuring of tasks in a transition period which had been expected in some supplier circles.

In addition, several suppliers of artificial turf pitches have stated that more pitches, approx. ten, are already being established.

4.2.1.2 Pitch maintenance experiences (salting etc.)

In relation to the maintenance of artificial turf pitches, experience is are limited as most third-generation pitches have been established in recent years (2002 and later).

All football clubs and municipalities contacted, except from one respondent, have stated that they winter salt the pitches as required. The volume of salt used has not been stated for most of the pitches.

If stated, the volume is between one to 16 tonnes per season. The figure of 16 tonnes was stated by a municipality in the Greater Copenhagen Area which has found it difficult to use snow removal machines. The figure is from the winter 2005/2006, which saw periods with a lot of snow.

Both dry salting and salt solutions have been used. One respondent states that 150 kg of dry salt is used per application. Another states 200-400 kg salt is used per application in conditions with light frost and little snow.

Both sodium chloride and potassium chloride are used in connection with the salting.

One of the respondents states that magnesium chloride is used under conditions with severe frost and a lot of snow.

None of the respondents stated that they use urea for defrosting pitches, but one artificial turf supplier recommends urea.

One municipality provided detailed information about salting.

During the 2004/2005 season, a total of 136 tonnes of road salt was used for two pitches (second-generation pitches), during the 2005–2006 season, 150 tonnes of salt was used for the pitches, while only 16 tonnes of road salt was used during the 2007 season which saw very little snow. The reduced consumption is, among other things, a result of an upgrade to third-generation pitches with rubber infill. Rubber maintains its elasticity even at frost temperatures and the salting requirement is thus expected to be heavily reduced.

In snowy conditions, salting is still expected. The municipality has based its calculation on six snowy days a year. As two tonnes of salt per application is expected, the estimated consumption will be six tonnes for three pitches, i.e. a total of 36 tonnes per season.

However, one of the large suppliers of artificial turf pitches states that several pitches are not salted, but only cleared of snow using snow removal machines.

With respect to any use of herbicides or biocides, only one of the clubs contacted states that they have used Round Up once. All other clubs contacted stated that they had not used herbicides.

Most of the pitches are still so new that they have yet to be filled with new infill material. One respondent (a high school for physical education) states that eight tonnes of a new infill is expected to be used over a period of five years.

4.2.1.3 DBU’s guides on establishing and maintaining artificial turf pitches

DBU’s website contains a guide on and a description of how to establish artificial turf football pitches (DBU, 2005) as well as a leaflet with good advice on maintaining third-generation artificial football pitches (DBU, 2004).

A distinction is made between DBU, category 1 certificate pitches and DBU, category 2 certificate pitches. The category 2 pitches are only filled with silica sand while category 1 comprises FIFA STAR** and FIFA STAR* pitches with rubber granule and silica sand fillings. DBU, category 1 also covers pitches with a UEFA certificate established before 31 December 2005.

In the DBU, category 1, the sublayer must be in the form of a laid-out rubber pad or a polyurethane-bound ET base course. In connection with the rubber pad, an additional bitumen-bound single-layer cast drainage asphalt base course can be used. For artificial turf surfaces with leaves >/= 60 mm, a sublayer can be deselected. However, for FIFA STAR** for stadiums, there is a requirement for underlying padding.

For FIFA STAR**, artificial turf straight leaves of 50-70 mm in length must be used, and FIFA STAR* requires the leaves to be >/= 40 mm. Mono or split-fibres can be used for both types.

In connection with the selection of a surfacing system, the following must be considered:

- Sports functional properties

- Material technological properties

- Warranty

- Maintenance

- Price

Alternative surfacing options are available (selection and thickness of material), but the owner will ultimately make the final decision in this matter.

If a polyurethane casting is used, the contractor must document compliance with statutory requirements in connection with the handling of the polyurethane and that the required permits have been given.

The maintenance guide offers a number of practical tips on pitch maintenance. An important element is compliance with the guide prepared by the supplier. The tips include regular maintenance in the form of cleaning, marking, deep-cleaning, surface loosening, filling up and watering. Watering can be relevant during the summer months with respect to cooling down and reduced friction.

There is also a guide on winter maintenance, including salting. Salting must be approved by both the turf supplier and the rubber granule supplier. It is stated that the use of salt solution (e.g. in a mixing ratio of 1:6) seems more effective that spreading dry salt. Presalting should only be performed if frost is expected or during a change from frost to thaw. It is recommended that sodium chloride be used for the salting, but according to the guide, potassium chloride can also be used. There is a comment that large salt volumes in the long term can impede water permeability in the gravel bed.

DBU[3] estimate on the annual consumption of materials in connection with maintenance:

- Salt in the form of sodium chloride or calcium chloride, two tonnes at DKK 2,000

- Filling up with rubber granules, three tonnes at DKK 5,000

According to DBU, there should be a minimum warranty period of five (5) years and the pitch depreciation is estimated at ten (10) years. This only applies to the pitch surface, the artificial turf and the removal of old artificial turf.

The pitch supplier must be able to document compliance with the materials quality and local environment and fire regulations.

The third-generation artificial turf pitches differ from the second-generation pitches in having leaves that are significantly longer (approx. 50-70 mm compared to 30 mm previously), in having infill which consists of a layer of silica sand at the bottom of the sward and a rubber granule layer at the top (or a mixture of the rubber granule and sand) and having approx. 20 mm of the artificial turf not being filled.

It is stated that the new pitches abroad are laid directly on a flattened gravel layer (frost-proof) without a bound base course, but some pitches are laid with a shock-absorbing pad between the gravel and the artificial turf. All second-generation pitches in Denmark have so far been laid on a bound base course.

DBU has prepared an estimate of the establishment costs for second- and third-generation artificial turf pitches. The estimated establishment costs are DKK 4.9 million and DKK 5.5-6 million, respectively.

4.2.1.4 Other comments on artificial turf pitches

A few respondents state that odour problems may occur in hot weather (rubber smell). The smell of rubber originates from a number of volatile sulphur compounds, lower organic acids (butyric acid and valeric acid) and terpenes, among others.

Generally, the municipalities and football clubs surveyed indicate a high degree of satisfaction among users as regards the playing properties of the artificial turf pitches.

However, one respondent states that professional football players prefer natural turf pitches.

The Danish football players’ association website www.spillerforeningen.dk (in Danish only) hosts an ongoing debate on artificial turf pitches. The association conducted a questionnaire survey on this topic. Players prefer playing on natural turf, but they recognise the advantage of being able to also train in winter on artificial turf pitches. There is a debate as to whether tournament matches can be played on artificial turf as well as natural turf.

The survey indicates that many people are interested in the environmental debate in connection with artificial turf.

4.2.2 Monitoring parameters

Based on the knowledge gathered (see chapter 3) about the materials used in artificial turf pitches in the form of the artificial turf mat, elastic infill and possibly an elastic sublayer in the form of a pad, the following substances, based on the available material knowledge about the chemical substances which are part of the recipes or which are present as degradation products, could be relevant to monitor:

- Heavy metals