Survey of Chemical Substances in Consumer Products, No. 89, 2007

Analysis of chemical substances in balloons

Contents

- 1.1 Nitrosamine formation

- 1.2 Legislation/ recommendations on limit values for nitrosamines and nitrosatable substances in balloons based on laboratory analyses, etc.

2 Analysis of balloons on the market

4 Selection of balloons for analysis

6 Supplementary identification by GC/MS-headspace analysis

7 Analysis for nitrosamines and nitrosatable substances

8 Analysis for bioavailable heavy metals

Preface

The project ”Analysis of chemical substances in balloons” has been carried out by Danish Technological Institute in the period from mid March 2006 to mid November 2006.

The project has been headed by project manager lic.scient. Nils H. Nilsson, Materials Division, who has also been the responsible contact person to the Environmental Protection Agency (EPA).

The contact persons at EPA were Peter Hammer Soerensen and Frank Jensen.

The purpose of the present project was to investigate whether balloons contain or liberate any chemical substances hazardous to health. Principal focus has been on nitrosamines, nitrosatable substances or other degradation/conversion products formed from accelerators and other rubber chemicals used.

Summary and conclusion

For this study 20 different packs of balloons have been purchased at different retailers. The balloons normally come in different colours and the various brands differ in size and geometry.

During the purchasing phase we went to a number of supermarkets and the general impression was that the Danish balloon market is limited to a few wholesalers, supplying the same products to different supermarkets and therefore our purchases were confined to only three supermarkets. Other types of shops have also been included in our analysis but still the general impression is that only a few wholesalers/manufacturers are dominating the Danish balloon market.

As balloons are dangerous toys for children less than 8 years labelling regulations are laid down in the Toys Act 88/378/EEC. According to the standard in the Toys Act, EN 71-1, the balloons shall to in order comply with the CE-standard be provided with warning labels saying that children under 8 years should be supervised and that defective balloons or parts hereof shall be discarded. A further requirement is that the balloons made of natural latex shall be marked ”contain natural rubber latex”.

The labelling of the purchased balloons differs a lot. Most of them are however CE labelled and most of the packaging had warning labels about use by children under 8 years. Further, the packaging often advised caution with children less than 3 years. In some cases the warnings were not in Danish and some of the balloons had inadequate labelling.

The majority of the balloons are made of natural latex, but more of them had no informative label about this.

Twelve of the purchased balloons have been screened by thin layer chromatography (TLC) in order to determine the accelerator types used by vulcanisation.

On basis of these screenings and the amount of extracted substance four balloons were selected for analysis for nitrosamines and nitrosatable substances according to DS/EN 12868, ”Child Care Articles: Methods for determination of the release of N-nitrosamines and N-nitrosatable substances from bottle teats and soothers of elastomers or rubber”. Likewise, analyses have been made on release of volatile substances from balloons at 80 °C. Further, three balloons were selected for test of bioavailable heavy metals according to EN 71-3 ”Safety of Toys - Migration of certain elements.

The result was that there was no measurable release of heavy metal, but all the balloons gave off nitrosamines in concentrations higher than allowed for soothers and bottle teats. Surprisingly, the release of nitrosatable substances was generally in very high concentrations. In two cases the contents was so high that the standardised method could not completely convert those of the amines, which were highest in concentration, within the reaction time for conversion to nitrosamines. It is therefore assessed that this method provides too low results for nitrosatable substances at high amine concentrations. Not unexpectedly, the most frequent nitrosatable amine is dibutylamine, which is often present as accelerator in vulcanised latex products in the form of the zinc salt of dibutyldithiocarbamic acid. Second comes the zinc salt of dimethyldithiocarbamate, which is often applied in combination with the zinc salt of dibutyldithiocarbamatic acid.

Germany has laid down limit values for release of nitrosamines and nitrosatable substances from balloons.

The analysed balloons all complied with the limit value of 0.2 mg/kg for migration of nitrosamines according to DS/EN 12868, but only one of the four analysed balloons complied with the requirement to nitrosatable substances of 2 mg/kg. This balloon type bore the TÜV quality mark.

At 150 °C a headspace GC/MS analysis was made of the volatile substances formed by decomposition of rubber chemicals. A wide range of different degradation products are formed from the chemical substances in the balloons. This analysis has been used to confirm the results from the TLC screening.

The analysis established evaporation of several hazardous organic substances from a balloon purchased in a discount store. The other three balloon types showed no degassing of these chemical substances.

A headspace analysis at 80 °C of the balloons demonstrated liberation of carbon disulfide from the four analysed balloons. The balloon from the discount store also liberated dibutylamine and BHT (antioxidant).

1 Introduction

- 1.1 Nitrosamine formation

- 1.2 Legislation/ recommendations on limit values for nitrosamines and nitrosatable substances in balloons based on laboratory analyses, etc.

Balloons are popular toys among children and the market offers a variety of different balloons. Even though balloons are not recommended for children under three years it is most likely that children of that age will get in contact with balloons.

Almost all the balloons are made of natural latex.

Special focus is on the release of nitrosamines from balloons as several studies have shown that carcinogenic nitrosamines are given off in migration tests to artificial saliva. The nitrosamines are formed from secondary amines liberated from the accelerators used.

Other substances might be harmful to the health, i.a. problematical such as thiuram accelerators and mercaptobenzothiazole (MBT), which may cause type IV-allergy.

Balloons are dyed in different colours and therefore colorants may also present a risk.

Finally it is a well-known fact that for a small part of the population the proteins in natural latex may cause type I-allergy, which may be life threatening.

This aspect will not be studied in detail in this limited project, but it should be added that especially by bursting of balloons there is a risk of affecting the proteins if the balloons are powdered with corn starch or other release agents (talc) which are added to the finished product in order to reduce the tackiness of the rubber.

Natural rubber is extracted from the tree Hevea Brasiliensis, where the rubber latex is drained from the cortex in the form of latex.

The latex is stabilised with ammonia to avoid coagulation. Immediately after dispersing of rubber chemicals the latex can be used for production of balloons or other dipped products (e.g. bottle teats, gloves and condoms). A prevulcanisation will often take place when heating the latex solution to 60-70 °C for a shorter period (approx. 6 hours). The latex used for balloons normally has a dry matter content of 60 % w/w.

1.1 Nitrosamine formation

Nitrosamines can be formed oxidatively from the amines that can be liberated from the applied thiuram-ultra accelerators during vulcanisation of the natural latex.

The most common accelerators for dipped latex products are the following:

- Zink dimethyl dithiocarbamate ZDMC

- Zink diethyl dithiocarbamate ZDC

- Zink di-n-butyl dithiocarbamate ZDB

- Zink ethylphenyl dithiocarbamate ZEPC

- Zink dibenzyl dithiocarbamate ZBED

- Zink pentamethylene dithiocarbamate ZPD

The most frequently applied accelerators are salts of dithiocarbamic acid in the form of zinc dimethyldithiocarbamate, zinc dimethyldithiocarbamate and zinc di-n-butyldithiocarbamate in the order given.

By vulcanisation carbon disulfide will be formed during the release of the secondary amines, which are part of the chemical building blocks for the accelerators:

- Dimethylamine

- Diethylamine

- Di-n-butylamine

- Diethylphenylamine

- Dibenzylamine

In the presence of nitrosatable substances (NOX) all five secondary amines can form nitrosamines.

Due to the low vapour pressure the nitrosamine from dibenzyl amine is considered to be relatively unproblematic in health terms, but is still one of the nitrosamines to be quantified according to DS/EN 12868.

Nitrosamines may also be formed from other accelerators or sulphur donors, which might be ingredients in the latex recipe, e.g. dimethylthiuram mono- and disulfide, diethylthiuram mono- and disulfide as well as 4,4´-dithiomorpholine.

2-Morpholino-benzothiazole sulfenamide is a sulphenamide accelerator, which may cause formation of N-nitroso-morpholine.

MBT is a mercaptothiazole accelerator, known as a medium strong accelerator, and which is also being used as accelerator in natural rubber latex.

It is used by dipped products together with ultra accelerators of the thiocarbamate or the thiuram type to provide improved process safety. Further, MBT is being used within production of technical rubber products as it is one of a few accelerator types which do not give off nitrosamines during vulcanisation.

1.2 Legislation/ recommendations on limit values for nitrosamines and nitrosatable substances in balloons based on laboratory analyses, etc.

There is, however, no actual legislation for balloons as is the case for e.g. teats for soothers and feeding bottles. However, balloons, which are marketed and sold in Germany must comply with the German limit values laid down for consumer products according to BgVV recommendation XXI.

Based on exposure scenarios the BfR ”Bewertung von Nitrosaminen in Luftballons” (ref. 4) has laid down a maximum liberation of nitrosamines from balloons of 0.2 mg/kg and 2 mg/kg for nitrosatable substances.

EU directive 93/11/EEC stipulates that rubber teats and soothers may not release nitrosamines and nitrosatable substances in amounts larger than 10 µg per kg rubber for nitrosamines and 100 µg per kg rubber for nitrosatable substances for artificial saliva (DS/EN 12868). In the USA the limit value by a dichlormethane extraction of 20 µg per kg for soothers and 10 µg per kg for rubber teats.

A German investigation has shown that for approx. 81% of the investigated balloons in 2001, the release of nitrosamines and nitrosatable substances (nitrosamine precursors) for artificial saliva according to EN 12 868 (1 hour at 40 °C) was higher than the limit values applying for soothers and rubber teats.

An analysis in 2003 of 14 balloons established that only one of these complied with the limit value of less than 10 µg per kg for nitrosamines.

The nitrosamines found in the investigation were N-dimethylnitrosamine (97 % of the balloons), N-dibutylnitrosamine (93 % of the balloons) and diethylnitrosamine (34 % of the balloons). In 9 % of the balloons was found N-nitrosomorpholine.

It is not surprising to find the three first-mentioned types of nitrosamines, as the most frequently used accelerators in natural latex will be capable of forming these nitrosamines. The presence of N-nitrosomorpholine in 9 % indicates that morpholine derivates are being used either as sulphur donor or as accelerator (sulfenamide types).

According to ref. 3 the European industry has responded to the proposed amendment to the Toys Directive concerning nitrosamines in balloons, that the industry is aware of the risk, but that there is presently no available technology for complete elimination of the nitrosamines. It is further stated that a possible total ban on nitrosamines in balloons will fall notably hard on the European balloon industry and in the worst case it completely close the industry.

2 Analysis of balloons on the market

The analysis of the balloon market is based on visits to different types of shops.

The purpose of the analysis is to reveal which balloon brands are being sold to the consumers.

The following shop types were visited:

- Toy stores

- Fun items shops

- Supermarkets

- One department store

- One bookshop

- One discount shop

Further, we have had contact to a local Danish balloon manufacturer.

Two copies of each balloon type on the market were purchased and one copy was sent to EPA.

At this initial phase information was retrieved from wholesalers and manufacturers about the accelerators they had used and whether the balloons had certificates regarding any regulatory compliance.

DTI has previously experienced that it is rather difficult to gather information about substances in consumer products – in particular from the Far East where the majority of the balloon types are produced.

Contacts to importers or distributors confirm this, as the general picture is that when it comes to the chemical composition of the balloon latex, there are no records on the accelerators or the other chemicals added to the balloons.

The link to the balloon manufacturer in the Far East may be through a European wholesaler/buyer in another EU country, for instance Germany.

3 Purchased balloons

In total 20 different balloons have been provided for the project. The balloons were purchased in toy stores, supermarkets, a department store, a bookshop, a fun items shop and in a discount store. Records were made on the data on the packaging as to CE labelling, warnings about use and other consumer information. The records appear from Table 3.1.

Table 3.1 Purchased balloons

| Product nr. | Shop type | Consumer information | Comment |

| 1 | Toys shop | CE labelled, warning < 8 years (i.a. in Danish). Not for 0-3 years , contains small parts. Natural latex |

Balloon figures in different colours (40 pcs.) |

| 2 | Toy store | CE labelled, warning, not for children under 8 years. Warning symbol 0-8 years | Funny face balloons (6 pcs.) |

| 3 | Toy store | CE labelled, warning in Danish, not for children under 8 years. Warning symbol 0-8 years, natural latex, balloon pump recommended | Ass. balloons in different colours (20 pcs.) |

| 4 | Toy store | CE labelled, warning in Danish, not for children under 8 years. Warning symbol 0-8 years, natural latex, balloon pump recommended. | Modelling balloons with pump. Different colours (15 pcs.) |

| 5 | Toy store | CE labelled, warning < 8 years (i.a. in Danish). Not recommended for 0-3 years, natural latex, balloon pump recommended |

Red, yellow, and green (3 pcs.) |

| 6 | Toy store | CE labelled, warning < 8 years (i.a. in Danish). Not recommended for 0-3 years, natural latex, balloon pump recommended |

Metallised balloons (8 pcs.) |

| 7 | Toy store | CE labelled, warning < 8 years (i.a. in Danish). Not recommended for 0-3 years, natural latex, balloon pump recommended |

Metal balloons in red and white (10 pcs.) |

| 8 | Supermarket | CE labelled, warning < 8 years (i.a. in Danish). Not recommended for 0-8 years warning symbol, natural latex, |

Metal balloons in blue, grey and green (8 pcs.) |

| 9 | Supermarket | Not CE labelled. Caution: Not recommended for children less than three years | Pink and mauve balloon (2 pcs.). Probably in natural latex, but not labelled |

| 10 | Supermarket | CE labelled, warning < 8 years (i.a. in Danish). Not recommended for 0-8 years, warning symbol |

Balloons in four colours (8 pcs.). It is stated that it is based on natural latex, however, not in Danish |

| 11 | Toy store | CE labelled, warning text not for < 8 years, but not in Danish, warning symbol > 0-8 years | Balloons in three colours (6 pcs.). Probably in natural latex, but not labelled as such |

| 12 | Department store | CE labelled, warning < 8 years (i.a. in Danish) Not for 0-8 years warning symbol, Natural latex, |

Balloon figures in different colours (10 pcs.) |

| 13 | Department store | CE labelled, warning in text, for children under 8 years | Balloons in different colours (50 pcs.), probably in natural latex, but not labelled |

| 14 | Supermarket | CE labelled, warning i.a. in Danish for children under 8 years, no warning symbol | Balloons in different colours (50 pcs.), probably in natural latex, but not labelled |

| 15 | Fun items shop | Not CE labelled, warning symbol for 0-3 years. Warning for children less than 8 years i.a. in Danish, Do not put in mouth. To be inflated only with balloon pump. | Balloons in different colours (13 pcs.) |

| 16 | Discount store | CE labelled, warning sign 0-3 plus text – not recommended for children under three years | Red balloons. probably in natural latex, but not labelled |

| 17 | Bookshop | Not CE labelled, but texted not for children under 3 years | Round balloons in white and red (10 pcs.). Probably in natural latex, but not labelled. |

| 18 | toy store | CE labelled, texted not for children under 3 years, contains particles | Self-inflatable metallised balloon (1 pc.). Hardly natural latex-based |

| 19 | Supermarket | CE labelled, warning < 8 years(not in Danish) Not for 0-3 years, Tüv Q-label |

Blue, yellow, red (6 pcs.) |

| 20 | Supermarket | CE labelled, warning < 8 years (not in Danish) Not for 0-3 years, Tüv Q-certificate |

Orange, yellow, red (6 pcs.) |

4 Selection of balloons for analysis

Twelve balloons were chosen for an initial screening for accelerators by thin layer chromatography (TLC). The following were selected:

Balloons numbered 1, 3, 6, 8, 10, 11, 13, 14, 15, 16, 17, and 20.

The priority criteria were:

- The balloons must be made of or presumedly made of natural rubber latex

- The selected balloons must represent manufacturers from Denmark and abroad

- Both discount and luxury balloons should be tested

- Balloons with special appeal to children under 8 years

Based on results from the TLC-screenings 4 different balloons were selected for analysis for nitrosamines and nitrosatable substances according to analysis method DS/EN 12868 ”Children Care Articles. Methods for determining the release of N-nitrosamines and N-nitrosatable substances from elastomers or rubber teats and soothers”, 1st edition 2000-01-21.

Following were chosen based on the TLC-results and extraction yields for dichlormethane as solvent: Balloons nos. 3, 6, 16, and 20.

Additionally three types of balloons were selected for heavy metal analysis according to DS/EN 71-3 ”Toys Safety Regulations – Part 3: Migration of certain elements”.

Following samples were chosen: Balloon no. 10 yellow, no. 16 red and no. 20 orange.

The choice was made from the following criteria:

- Orange, yellow and red colours may be cadmium-based

- One of the balloon types is a discount product and does not comply with the requirements to CE-labelling, although it had a CE label.

- One of the products had famous comic strip figures and had TÜV-quality mark.

Additionally four balloon types were selected for GC/MS-screening for liberated chemical substances from the accelerators according to the methods previously used by DTI at consumer products analyses. The selection is the same as for the analysis for nitrosamines and nitrosatable substances, i.e. balloons nos. 3, 6, 16 and 20. The analyses have been carried out at a headspace of 80 °C and 150 °C, respectively.

5 Screening analysis by TLC

5.1 Sample preparation and method of analysis

5.1.1 Introduction

Thin layer chromatography (TLC) is a preferred chromatographic method for determination of the accelerators used by vulcanisation of rubber, cured as well as uncured. Methods for determination of the applied accelerators are i.a. standardised in ISO 10398 ”Rubber – Identification of accelerators in cured and uncured compounds” (1998) and ”Kunststoffe im Lebensmittelverkehr” XXI BII, 2.5.

An important reason for using TLC for analysis of accelerators in rubber is that the accelerators are being decomposed at higher temperatures and thus cannot directly be analysed by gas chromatography. Moreover it is common to use zinc salts of dithiocarbamine acids, which makes the HPLC less attractive as analysis method. Finally, it is possible to spray TLC plates with reagents which yield colour according to the applied chemical substance class.

5.1.2 Sample preparation

The extraction of accelerators is made by weighing out 3 g shredded balloon and extraction with 50 ml dichlormethane 1 hour in ultrasonic bath. The solvent is decanted and flushed with 25 ml dichlormethane. The procedure is repeated and the extracts are collected and evaporated. The evaporation residue is dissolved in 2 ml dichlormethane for the TLC analysis. The amount of evaporation residue can be seen from the below table.

Table 5.1 Evaporation residue from the dichlormethane extraction

| Balloon nr. | 1 | 3 | 6 | 8 | 10 | 11 | 13 | 14 | 15 | 16 | 17 | 20 |

| %w/w | 4.9 | 4.9 | 3.2 | 2.7 | 4.2 | 3.0 | 3.3 | 3.7 | 5.0 | 5.7 | 2.9 | 4.0 |

5.1.3 The TLC-analysis

As developing solvent a mixture of hexane, toluene and methanol in the proportions 30:58:12 was chosen.

For the visualisation UV-light, 1 % cuprisulphate solution and iodine vapours were used.

Silica TLC-plates from Merck (Article 1.11798) 20 cm x 20 cm Silica 60 F 254 with concentration zone were used. 5 µl of the concentrated sample extracts and produces standards were added. The elution of the applied samples and standard substances took place over a distance of 12 cm from the start zone.

The reference substances listed in the table were used in concentrations of 1 %. The references were dissolved in dichloromethane, acetone or a mixture of these.

Table 5-2 Reference substances used for for the TLC-screening.

| Reference substance | Abbr. | CAS nr. |

| 4,4-Dithiodimorpholine | DTDM | 103-34-4 |

| Dibenzothiazolyl disulfide | MBTS | 120-78-5 |

| 2-Mercaptobenzothiazole | MBT | 149-30-4 |

| N-Morpholinyl-2-benzothiozole sulfenamide | MBS | 102-77-2 |

| Tetramethyl thiurammonosulfide | TMTM | 97-74-5 |

| Zinc dibenzyl dithiocarbamate | ZBEC | 14726-36-4 |

| Zinc dibutyl dithiocarbamate | ZDBC | 136-23-2 |

| Zinc diethyl dithiocarbamate | ZDEC | 14324-55-1 |

| Zinc dimethyl dithiocarbamate | ZDMC | 137-30-4 |

5.1.4 Results from the TLC-screenings

Table 5-3 Survey scheme TLC-screening

| Balloon no. | Result |

| 1 | ZDBC, (ZBEC), ZDMC |

| 3 | ZDBC (ZBEC), ZDMC |

| 6 | ZDBC (ZBEC),ZDMC |

| 8 | ZDBC (ZBEC) |

| 10 | ZDBC (ZBEC) |

| 11 | ZDBC (ZBEC) |

| 13 | ZDBC (ZBEC), ZDMC |

| 14 | ZDBC (ZBEC), ZDMC |

| 15 | ZDBC (ZBEC) |

| 16 | ZDBC (ZBEC) |

| 17 | ZDBC (ZBEC) |

| 20 | ZDBC (ZBEC),ZDMC |

In the chromatographic system it is not possible to differ between zinc salts of dibenzyldithiocarbamate (ZBEC) and of dibutyldithiocarbamate ZDBC), as they have the same Rf-value (the Rf-value is obtained by dividing the position of the substance in the chromatogram by the total possible distance (12 cm).

The literature (ref.-1) states that it will most likely be ZDBC based on either di-n-butylamine or di-isobutylamine.

According to FDA (Food and Drug Administration, USA) ZDBC may be used in amounts of up to 1.5 % in products intended for repeated contact with foodstuffs. Similar limits are stated in Kunststoffe im Lebensmittelverkehr, i.e. 1.2 % for zinc-dialkyldithiocarbamate accelerators.

The TLC screening cannot with certainty verify the presence of any of the other reference substances used at the screening. This applies for 2-MBT and MBS and for thiuram mono- and disulfides based on dimethyl-, diethyl- and dibutylamine.

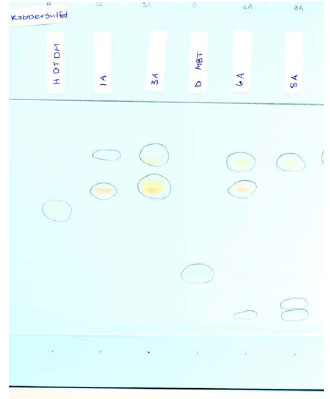

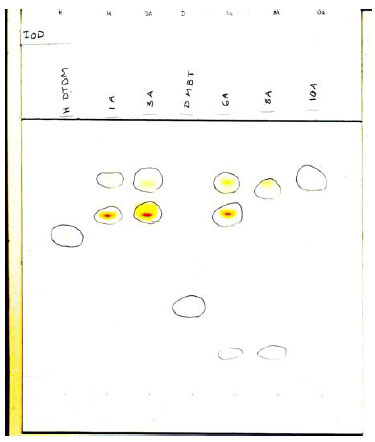

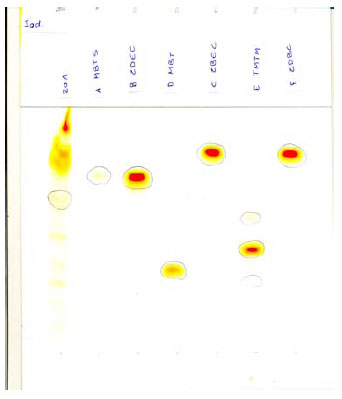

Examples of TLC chromatograms are shown below:

Fig. 5.1 TLC of balloon nos. 1, 3, 6, and 8. Visualisation by cupri sulphate

Fig. 5.2 TLC of extract from balloon 1, 3, 6, 8, and 10. Visualisation by iodine vapour

Fig. 5.3 TLC of balloon no.. 20 and a number of reference substances. Visualisation iodine.

There are individual differences in the TLC chromatograms for the selected balloons. Partly, colorants were detected in some of them, partly, chemical substances were detected with a relatively low Rf-value, and partly a colour reaction occurred after the copper sulphate visualisation which seems to indicate the presence of a substance with the same value as the zinc salt of dimethyldithiocarbamate (balloon nos. 1, 3, and 6), which gives quite another colour tone (reddish instead of yellow-green).

6 Supplementary identification by GC/MS-headspace analysis

6.1 Verification by GC/MS-headspace analysis at 150 °C

6.1.1 Introduction

As there was no unambiguous verification of accelerators by the thin layer chromatography, a headspace analysis at GC/MS at 150 °C was carried out on the balloons selected for analysis for nitrosamines and nitrosatable substances. At this temperature the accelerators will decompose and the decomposition products can give information about the accelerator types applied.

6.1.2 Method

The analysis is performed by headspace GC/MS at 150 °C after one hour’s exposure. The numerous different chemical substances formed and identified by the analysis have not been quantified. The relative amount of the chemical substances has instead been valuated from the area percentages in the chromatogram.

6.1.3 Results from the verification analysis

The number of organic compounds detected by the GC/MS verification analysis at 150 °C appears from Table 6.1.

Table 6.1 Headspace analysis 150 °C of 4 selected balloons

| Balloon no. | 3 | 6 | 16 | 20 | |

| Chemical substance | CAS-nr. | Area % | |||

| Ethanol | 64-17-5 | - | - | 0.58 | 0.25 |

| Dimethylamine | 124-40-3 | - | 0.27 | - | - |

| Acetone | 67-64-1 | 4.57 | 4.35 | 6.86 | 4.16 |

| Carbon disulfide | 75-15-0 | 8.95 | 20.98 | 11.25 | 3.29 |

| 2-methylpropenal | 78-84-2 | - | 0.71 | 0.85 | 0.17 |

| Methacroleine | 78-85-3 | 3.37 | 3.07 | 3.84 | 3.17 |

| Methylvinylketone | 78-94-4 | 5.92 | 4.05 | 2.44 | 3.19 |

| Acetic acid | 64-19-7 | - | 0.85 | - | - |

| Butanal | 123-72-8 | <1 | - | 5.44 | 0.72 |

| 2-methylfurane | 534-22-5 | 1.84 | 3.81 | 4.86 | 1.69 |

| 3-methylbutanal | 590-86-3 | - | 0.95 | 1.2 | 0.27 |

| Benzene | 71-43-2 | - | - | 2.44 | - |

| Hydroxyacetone | 116-09-6 | 1.65 | 0.77 | - | 0.3 |

| Ethylenglycol | 107-21-1 | 4.04 | 14.27 | - | 1.31 |

| N,N-dimethylthioacetamide | 631-67-4 | - | 0.31 | - | - |

| Pentanale | 110-62-3 | 1.01 | - | 0.8 | - |

| Propoylenglycol | 57-55-6 | 1.17 | - | - | - |

| ?, maybe 3-methyl-1,4-heptadien or 2,4-heptadienal | 1603-01-6 | 4.5 | 3.08 | 2.82 | 3.24 |

| Pyrrol | 109-97-7 | - | - | 0.59 | - |

| Dimethylcyanamide | 1467-79-4 | 0.6 | 0.46 | 0.22 | - |

| Dimethylformamide or 2-butanamine | 68-12-2 | 2.91 | 3.52 | 0.53 | 0.54 |

| Ethylacetate | 141-78-6 | 1.77 | 1.11 | - | - |

| Hexanal | 66-25-1 | 1.29 | 0.94 | 1.23 | 0.74 |

| 2-methyl-pyridine + isomers | 109-06-8 108-99-6 |

- | - | 0.61 | - |

| Methyl-pyrazine | 109-08-0 | - | - | 0.44 | - |

| 2-methylpyrrol | 636-41-9 | 0.72 | 0.39 | 0.48 | 0.12 |

| Chlorobenzene | 108-90-7 | - | - | 0.5 | - |

| N,N-dimethylacetamide | 127-19-5 | - | 0.91 | - | - |

| ?, 6,10-dimethyl-5,9-dodecadiene-2-on or similar. | 1000132-10-9 | 1.31 | - | - | - |

| 1-(1-cyclohexen-1-yl)-ethanone | 932-66-1 | - | 0.39 | - | 3.19 |

| 5-methyl-3-methylene-5-hexene-2-one | 51756-18-4 | 4.59 | 2.82 | 2.77 | - |

| ? Cyclic alkane/alkene | - | 3.98 | - | - | |

| 2-hexen-1-ol acetate | 2497-18-9 | - | - | 1.14 | 0.73 |

| N-butyliden-1-butanamine | 4853-56-9 | - | - | 0.24 | - |

| ?Might be branched alkene | - | - | - | 4.41 | |

| 3,5,5-trimethylhexanal | 5435-64-3 | - | - | - | 4.11 |

| ?, Branched alkanes C10-C15 | - | - | - | 29.1 | |

| Ethylmethylbenzene isomer | 611-14-3 98-82-8 |

0.87 | |||

| Dimethyl-pyrazine | 123-32-0 108-50-9 |

0.53 | |||

| Dibutylamine | 111-92-2 | 12.47 | |||

| Phenol | 108-95-2 | 0.62 | |||

| 2-pentylfurane | 3777-69-3 | 0.46 | |||

| Aniline | 62-53-3 | 3.36 | |||

| ?, Maybe dimethylnitrosamine | 62-75-9 | 0.83 | 0.64 | ||

| ?, 2-methyl-2-butene-1-ol | 4675-87-0 | 8.67 | |||

| Benzaldehyde | 100-52-7 | 2.53 | 1.33 | ||

| Trimethylbenzene | 108-67-8 526-73-8 |

0.68 | |||

| ? Maybe 4,4-Dimethyl-1-hexene | 1647-08-1 | 1.75 | |||

| N,N-dimethylthioformamide | 758-16-7 | 3.27 | 2.1 | ||

| Dihydro-5-ethenyl-5-methyl-2-(3H)-furanone | 1073-11-6 | 8.01 | 3.85 | 2.94 | 5.12 |

| 1-Methyl-3-propylbenzene + isomers | 1074-43-7 | 5.18 | |||

| Undecane | 1120-21-4 | 1.62 | 0.91 | - | 10.75 |

| Methylaniline | 100-61-8 95-53-4 |

- | 0.66 | - | - |

| Acetophenone | 98-86-2 | 0.73 | - | - | - |

| Dodecane | 112-40-3 | 0.63 | 0.26 | - | 2.75 |

| 1,2,3,4-tetrahydronaphthalene | 119-64-2 | - | - | - | 0.33 |

| Dibutylnitrosamine | 924-16-3 | - | - | 0.54 | - |

| Benzothiazol | 95-16-9 | 2.23 | 1.23 | - | - |

| N,N-dibutylformamide | 761-65-9 | 1.03 | - | 2.95 | 0.13 |

| BHT | 128-37-0 | 0.99 | 0.34 | 10.95 | 0.2 |

| Hexadecene | 629-73-2 | 6.43 | - | - | - |

| ?, Maybe 3-eicosene | 74685-33-9 | 0.96 | 0.56 | 0.37 | - |

| Total % integrated peaks | 91 | 83 | 88 | 90 | |

As can be seen from Table 6.1 there are many different substance types, some originating from the used accelerators, others may be formed from the colorants. Balloon no. 16 is producing the most different substances in the headspace, i.a. chlorobenzene, benzene, aniline, and dibutylnitrosamine. These substances are not liberated in measurable amounts from the other balloons. Balloon no. 16 was bought in a discount shop.

All samples liberated carbon disulfide, largest amount from balloon no. 6 and smallest amount from balloon no. 20.

N,N-dibytylformamide was liberated from balloons nos. 3, 16, and 20. It is a typical degradation product from the zinc salt of dibutyldithiocarbamate. Balloon no. 16 is also liberating dibutylamine and the corresponding nitrosocompound. Dimethylamine is released from balloon no. 6 and dimethylformamide from all four balloons. It is a typical degradation product from derivates of dimethyldithiocarbamine acid.

6.2 Headspace analysis at 80 °C

An analysis of the liberated substances in headspace at 80 °C was performed. At this temperature only a minor decomposition of the added rubber chemicals will occur. The analysis results appear from Table 6.2.

Table 6.2 Concentration of volatile substances in headspace at 80 C in µg

| Chemical substance | CAS-no. | Balloon no. 3 | Balloon no. 6 | Balloon no. 16 | Balloon no. 20 |

| Carbondisulphide | 75-15-0 | 0.13 | 2.1 | 0.61 | 0.12 |

| Dibutylamine | 111-92-2 | Not detected | Not detected | 0.16 | Not detected |

| BHT | 128-37-0 | Not detected | Not detected | 2.8 | Not detected |

| 1,2-ethandiol | 107-21-1 | Not detected | 1,2 | Not detected | Not detected |

| Hydrocarbons | Not detected | Not detected | Not detected | 14 |

As can be seen only few volatile chemical substances are liberated at 80 °C. From previous studies it is known that carbon disulfide and dibutylamine are degradation products from zinc dibutyldithiocarbamate and that both are found in the rubber in spite of the low boiling point of carbondisulfide. BHT is a frequently applied and relatively volatile anti-oxidant and 1,2-ethandiol find use as a dispersing agent/ancillary substance. Hydrocarbons liberated may originate from the applied colorants.

There is a good matching between the results from degassing at 80 °C and at 150 °C, as the relative amount of volatile chemical substances detected at the low temperature are reflected in the chromatograms (lower area counts).

7 Analysis for nitrosamines and nitrosatable substances

Balloon nos. 3, 6, 16, and 20 were selected for analysis for nitrosamines and nitrosatable substances according to DS/ EN 12 868, which as previously mentioned is used by analysis of soothers and bottle teats. The selection is made on basis of the TLC screenings and the extraction yields from dichlormethane.

The standard lists 11 nitrosamines, which are causing health concerns in the mentioned products. Below is a list of the nitrosamines found in the analysed balloons with specification of concentrations. TIC is an abbreviation of total ion current by the mass spectroscopic detection.

Table 7.1 Migration of selected nitrosamines - Balloon no. 3

| CAS-no. | Content mg/kg (%RSD) | Detection limit mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 0.03* (10) | 0.004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0.005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0.004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0.005 |

| N-nitroso-dibutylamine | 89-16-3 | 0.08 (14) | 0.004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0.007 |

| N-nitroso-morpholine | 59-89-2 | - | 0.007 |

| N-nitroso-piperidine | 100-95-4 | 0.003** | 0.002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0.004 |

| Total | 0.08-0.11 |

* Maximum migration. Complete characterisation impossible due to coinciding peaks in TIC of extract..

** Maximum migration. Detected in only one of the two double determinations.

Table7.2 Migration of selected nitrosatable compounds - balloon no. 3

| CAS-no. | Content mg/kg (%RSD) | Detection limit mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 2.8 (2) | 0.004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0.005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0.004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0.005 |

| N-nitroso-dibutylamine | 924-16-3 | 8.1 (25) | 0.004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0.007 |

| N-nitroso-morpholine | 59-89-2 | - | 0.007 |

| N-nitroso-piperidine | 100-95-4 | 0.01* (2) | 0.002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0.004 |

| Total | 10.9 |

*Maximum migration. Complete characterisation impossible due to coinciding peaks in TIC of the extract.

Table 7.3 Migration of selected nitrosamines – Balloon no. 6

| CAS-no. | Content mg/kg (%RSD) | Detection limit Mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 0.02* (2) | 0.004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0.005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0.004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0.005 |

| N-nitroso-dibutylamine | 924-16-3 | 0.006; 0.01** | 0.004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0.007 |

| N-nitroso-morpholine | 59-89-2 | - | 0.007 |

| N-nitroso-piperidine | 100-95-4 | - | 0.002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0.004 |

| Total | 0-0.03 |

* Maximum migration. Complete characterisation impossible due to coinciding peaks in TIC of extract.

** Maximum migration. Double determination differs more than 25%.

Table 7.4 Migration of selected nitrosatable compounds - balloon no. 6

| CAS-no. | Content mg/kg (%RSD) | Detection limit Mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 2.7; 5.4 ** | 0.004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0.005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0.004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0.005 |

| N-nitroso-dibutylamine | 924-16-3 | 0.08; 0.12 *** | 0.004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0.007 |

| N-nitroso-morpholine | 59-89-2 | - | 0.007 |

| N-nitroso-piperidine | 100-95-4 | - | 0.002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0.004 |

| Total | 2.8-5.4 |

* Maximum migration. Complete characterisation impossible due to coinciding peaks in TIC of extract.

** Maximum migration. Double determination differs more than 25%.

*** Maximum migration. Double determination differs more than 25%.

Table 7.5 Migration of selected nitrosamines - Balloon no. 16

| CAS-no. | Content mg/kg (%RSD) | Detection limit mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 0,02* (10) | 0,004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0,005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0,004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0,005 |

| N-nitroso-dibutylamine | 924-16-3 | 0,02; 0,03** | 0,004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0,007 |

| N-nitroso-morpholine | 59-89-2 | - | 0,007 |

| N-nitroso-piperidine | 100-95-4 | 0,004* (0,5) | 0,002 |

| N-nitroso-diphenylamine | 86-30-6 | 0,006; 0,009 *** | 0,004 |

| Total | 0,03-0,04 |

* Maximum migration. Complete characterisation impossible due to coinciding peaks TIC of extract.

** Maximum migration. Double determination differs more than 25%.

*** Double determination differs more than 25%.

Table 7.6 Migration of selected nitrosatable compounds - balloon no. 16.

| CAS-nr. | Content mg/kg (%RSD) | Detection limit mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 2.6 (13) | 0.004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0.005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0.004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0.005 |

| N-nitroso-dibutylamine | 924-16-3 | 8.0 (7) | 0.004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0.007 |

| N-nitroso-morpholine | 59-89-2 | - | 0.007 |

| N-nitroso-piperidine | 100-95-4 | - | 0.002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0.004 |

| Total | 10.6 |

* Maximum migration. Complete characterisation impossible due to coinciding peaks in TIC of extract.

Table 7.7 Migration of selected nitrosamines - Balloon no. 20

| CAS-nr. | Content mg/kg (%RSD) | Detection limit mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | - | 0.004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0.005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0.004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0.005 |

| N-nitroso-dibutylamine | 924-16-3 | - | 0.004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0.007 |

| N-nitroso-morpholine | 59-89-2 | - | 0.007 |

| N-nitroso-piperidine | 100-95-4 | - | 0.002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0.004 |

| Total | - |

Table 7.8 Migration of selected nitrosatable compounds - balloon no. 20

| CAS-nr. | Content mg/kg (%RSD) | Detection limit mg/kg |

|

| N-nitroso-dimethylamine | 62-75-9 | 0,6 ; 1,3 ** | 0,004 |

| N-nitroso-ethylmethylamine | 10595-95-6 | - | 0,005 |

| N-nitroso-diethylamine | 55-18-5 | - | 0,004 |

| N-nitroso-dipropylamine | 621-64-7 | - | 0,005 |

| N-nitroso-dibutylamine | 924-16-3 | 0,2* (20) | 0,004 |

| N-nitroso-pyrrolidine | 930-55-2 | - | 0,007 |

| N-nitroso-morpholine | 59-89-2 | - | 0,007 |

| N-nitroso-piperidine | 100-95-4 | - | 0,002 |

| N-nitroso-diphenylamine | 86-30-6 | - | 0,004 |

| Total | 0,6-1,5 |

* Maximum migration. Complete characterisation impossible due to coinciding peaks in TIC of extract.

Not unexpectedly N-nitrosodibutylamine and N-nitrosodimethylamine are the present nitrosamine types and the nitrosatable substances are likewise dominated by dibutylamine and dimethylamine.

A comparison of the results with the regulations on soothers and bottle teats shows that the balloons are violating these requirements significantly. Conversion of the total migration of nitrosamines and nitrosatable substances to µg/kg gives the grand totals stated in the table.

Table 7.9 Survey of total migration of nitrosamines and nitrosatable compounds in the selected balloons

| Chemical class | Balloon no. 3 µg/kg |

Balloon no. 6 µg/kg |

Balloon no. 16 µg/kg |

Balloon no. 20 µg/kg |

| Nitrosamines | 80-110 | 0-30 | 30-40 | < 7 |

| Nitrosatable compounds | 10,900 | 2,800-5,400 | 10,600 | 600-1,500 |

Table 7.9 shows that balloon no. 20 as to the nitrosamine complies with the requirement to soothers and bottle teats. This may also be the case for sample no. 6. Balloons nos. 3 and 16 exceed the limit value of 10 µg/kg for soothers and bottle teats. All four samples comply with the German regulations on balloons, i.e. a maximum content of 200 µg/kg (0.2 mg/kg). Balloons nos. 3, 6 and 6 do not fulfill the requirements to neither the maximum content of nitrosatable substances according to the limit values for soothers and bottle teats of 100 µg/kg nor the German requirements to 2,000 µg/kg (2 mg/kg).

At the same time it is assessed that the analysis method does not provide a correct value of the nitrosatable compounds at concentrations as high as they occur in balloons nos. 3 and 6, because of insufficient time for nitrosation of the amines. It can be seen that dibutylamine is still present in the chromatogram, although it is nitrosatable.

It should be mentioned that N-nitroso-diphenylamine, which has been detected in balloon no. 6, is used as retarder by vulcanisation of rubber (reducing the reaction velocity), but it is not likely that it is used by production of rubber products in Europe due to its harmful properties (Xn R22, R43, R51/53, S24, S36, S60, S61).

N-nitroso-piperidine may originate from the use of piperidine pentamethylene dithiocarbamate which will liberate piperidine at the vulcanisation temperature.

8 Analysis for bioavailable heavy metals

The analysis results of the three balloon types selected for determination of release of heavy metals according to DS/EN 71-3, appear from Table 8.1.

Table 8.1 Bioavailable heavy metal according to DS/EN 71-3

| Lab. mark. | R32960-5 | R32960-10 | R32960-12 | |

| Sample mark. | Balloon no. 10 | Balloon no. 16 | Balloon no. 20 | |

| Element | Detection limit | |||

| Sb mg/kg | - | - | - | 6 |

| As mg/kg | - | - | - | 2,5 |

| Ba mg/kg | - | - | - | 25 |

| Cd mg/kg | - | - | - | 5 |

| Cr mg/kg | - | - | - | 2,5 |

| Pb mg/kg | - | - | - | 9 |

| Hg mg/kg | - | - | - | 2,5 |

| Se mg/kg | - | - | - | 50 |

| Ni mg/kg | - | - | - | 2 |

”-” less than the detection limit, which is 1/10 of the requirement value in the standard

Ni is not comprised by the standard but is included in the analysis.

As can be seen from Table 8.1, bio available heavy metals have not been detected in the analysed balloons, which means that no heavy metal-based accelerators (e.g. nickel dithiocarbamate salts) nor colorants have been used in the manufacture of the balloons.

9 Conclusion in short

It was established that several of the 20 different types of balloons purchased at retailers did not comply with the requirements to labelling. Some of the examples had a CE-label, although the requirements to the labelling according to EN 71 ”Safety of Toys” was not complied with.

Three different balloon types in the colours yellow, red, or orange, which were analysed for release of heavy metals according to EN 71-3, did not liberate measurable amounts to the contact liquid at a detection limit which was ten times lower than the requirement values.

Analyses for content of nitrosamines and nitrosatable chemical substances according to EN 12868 showed that none of the balloon samples were complying with the requirement to limit values for soothers and bottle teats.

However, the four analysed balloons complied with the German regulations (”Bewertung von Nitrosaminen in Luftballons” , Ergänzende Stellungsnahme des BfR vom 26. März) of 0.2 mg/kg for nitrosamines.

The limit value for nitrosatable substances is 2 mg /kg.

Only one of the analysed balloon types complied with the limit value for nitrosatable substances. All others did not meet the requirements.

The balloon type which complied with both requirements was according to the packaging certified by TÜV.

The chapter ”Summary and Conclusion” documents the analysis results in more detail.

10 References

- Asian dipped Goods handbook and directory 2004, John S. Powath, Rubber Asia, 1.udgave 2004

- Migration of nitrosamines from rubber products - are balloons and condoms harmful to the human health? Werner Altkofer et al. Mol. Nutr. Food Res. 2005, 49

- Study on the Impact of the Revision of the Counsil Directive 88/378/EEC on the Safety of Toys, Final Report RPA Oktober 2004

- Kunststoffe im Lebensmittelverkehr – 57. lfg. Oktober 2005, Bundesinstitut für Risikobewertung (BfR), Bevertung von Nitrosaminen in Luftballons

Version 1.0 December 2007, © Danish Environmental Protection Agency