[Front page] [Contents] [Previous] [Next] |

Waste 21

Appendix E Fractions

E 1 Batteries and accumulators

E 2 End-of-life vehicles E 2 End-of-life vehicles

E 4 Waste electrical and electronic equipment E 4 Waste electrical and electronic equipment

E 5 Packaging waste E 5 Packaging waste

E 6 Hazardous waste E 6 Hazardous waste

E 8 Impregnated wood E 8 Impregnated wood

E 10 Municipal sewage sludge E 10 Municipal sewage sludge

E 11 Refrigeration equipment E 11 Refrigeration equipment

E 12 Organic domestic waste E 12 Organic domestic waste

E 13 Organic waste from industry and food waste from catering centres E 13 Organic waste from industry and food waste from catering centres

E 14 Paper and cardboard E 14 Paper and cardboard

E 18 Residues from waste incineration plants E 18 Residues from waste incineration plants

E 19 Residues from power plants E 19 Residues from power plants

E 20 Shredder waste E 20 Shredder waste

E 22 Foundry waste E 22 Foundry waste

A number of waste fractions are discussed below. Several fractions play a significant role in Waste 21. Waste fractions have been selected because they constitute a special environmental problem.

Waste fractions are described whether or not new initiatives will be launched.

The EU has surveyed a number of waste streams with a view to having the Commission put forward proposals for regulation of these fractions. These fractions - the so-called "priority waste streams" - are discussed. Priority waste streams are health-care risk waste, end-of-life vehicles, waste electrical and electronic equipment, tyres, building waste, and chlorinated solvents. For these waste streams, initiatives have already been launched in Denmark.

Under each waste fraction status, future initiatives, objectives year 2004, and measures to be implemented to meet objectives are described. Implications of initiatives for national and local authorities are also described, and waste treatment capacity is assessed.

In order to achieve objectives for year 2004, the State and local councils must live up to their obligations, including the preparation of necessary rules and regulations, and citizens and enterprises must contribute to good waste solutions. Information and development activities planned require substantial support from the Environmental Council for Cleaner Products.

E 1 Batteries and accumulators

| Environmental problem | Batteries and accumulators may contain large quantities of

heavy metals, especially lead but also mercury, cadmium, and nickel. Non-collected nickel-cadmium batteries are the most significant source of cadmium in waste streams. Mercury is the largest barrier to efficient treatment of batteries. Some batteries also contain resources such as steel, zinc, manganese, and carbon that may be recovered. |

| Initiatives | When suitable separation and treatment methods have been developed, collection schemes for all types of battery will be established. |

Objective year 2004

| recover raw material resources in all batteries | |

| 99.9 % collection of lead accumulators | |

| 95 % collection of Ni-Cd batteries |

E 1.1 Status

Special collection schemes and suitable recycling methods exist for lead accumulators and nickel-cadmium batteries. The collection schemes work well.

In 1998, 14,900 tonnes of lead accumulators were sold in Denmark. This corresponds to the amounts of accumulators that, on an average, become waste every year. The collection rate for spent lead accumulators is 98 per cent, and the objective of 99.9 per cent in year 2000 is expected to be achieved.

It is assessed that 86 per cent of discarded batteries and accumulators derives from the service sector, 10 per cent from domestic waste, 2 per cent from bulky waste, and 2 per cent from industry. Accumulators mainly derive from the service sector, and from bulky waste.

Batteries may be subdivided roughly into two categories: single-use batteries and rechargeable batteries (see table).

| Types of battery | ||||||||||||||

Single-use batteries:

Rechargeable batteries:

|

In 1998 around 2,500 tonnes batteries were sold of which 260 tonnes were rechargeable.

According to assessments, some 120 tonnes of waste nickel-cadmium batteries were generated in 1997. Of these, 95 tonnes were collected for recycling. Nickel-cadmium batteries and lead accumulators are reprocessed in Sweden or France.

Experience from many years' collection of batteries in Denmark shows that it is difficult for consumers to distinguish between different types of battery, despite the fact that recyclable batteries carry a special recycling label. The result is that many consumers either collect all batteries regardless of type, or dispose of all types in domestic waste.

As a consequence, around half the discarded batteries are collected as a mixture of single-use and rechargeable batteries. The rest are disposed of in domestic waste.

Local authorities, municipal waste companies, and Kommunekemi A/S separate Ni-Cd batteries for recycling. The rest of collected batteries are landfilled. Mercury-bearing batteries are normally landfilled at the Kommunekemi A/S special landfill site, and other types at conventional landfills.

Mercury contents in batteries have in the past been an obstacle to reprocessing. In future, the major part of single-use batteries will not contain mercury, and in future they may be recovered. At international level, significant progress has been seen in the development of new technology for recovery of resources in new battery types. It is therefore expected that far more batteries can be recovered in future.

However, it is a prerequisite for efficient recycling that, in addition to recovery technology, reliable separation technologies are developed.

In a draft amendment to the EU Directive on batteries it is suggested that all batteries should be collected for separate reprocessing of different fractions.

Measures

| development of new treatment and separation methods |

E 1.2 Future initiatives

Initiatives to support the development of suitable methods of treatment and separation will be promoted.

When such methods have been developed, requirements for separate collection of all batteries will be made.

E 1.3 Regulation

Collection of batteries is regulated in the Statutory Order on waste80. Nickel-cadmium batteries, lead accumulators and lithium batteries as well as unseparated batteries are classified as hazardous waste, whereas clean fractions of, for example, non-heavy-metal-containing batteries are normally not considered as hazardous waste.

The collection of nickel-cadmium batteries and lead accumulators is also regulated by economic instruments, and collection is assumed by both private and public companies.

Collection of lead accumulators is ensured in an agreement between the Minister for Environment and Energy and the battery industries (Returbat), under which Returbat is liable for collection of all spent lead accumulators in Denmark. The agreement is supplemented by two Statutory Orders. The first Statutory Order81 lays down conditions for being registered as collector and thereby obtain subsidies. The second Statutory Order82 gives the financial basis for the scheme.

Returbat administers the scheme and, on the basis of an approved budget, receives funds from the Danish Environmental Protection Agency for remuneration.

Remuneration of maximum DKK 0.80/kg is granted to collectors delivering spent accumulators to approved recycling plants.

An environmental fee83 is levied on nickel-cadmium batteries. The fee is remunerated for the collection of spent nickel-cadmium batteries. In connection with the scheme, a Statutory Order has been issued84, stating criteria to be met by collectors of spent nickel-cadmium batteries in order to achieve a registration as a professional collector and thereby be granted remuneration.

The scheme is administered by the Danish Environmental Protection Agency.

A remuneration of DKK 120/kg is granted for spent Danish batteries delivered to an approved recycling plant.

E 1.4 Capacity

Capacity for recovery of lead, cadmium and nickel is available in Sweden and France.

Mercury-bearing batteries may be sent for treatment in, for example, Germany, the Netherlands and Switzerland.

E 1.5 Environmental assessment

The establishment of collection schemes for all batteries may lead to an even higher collection rate - also for nickel-cadmium batteries.

Furthermore, in the longer term, collection of all types of battery will lead to better financial utilisation of resources in more types of battery.

However, it is a prerequisite for utilisation of resources that mercury contents in batteries are reduced to a level where they do not present an obstacle to reprocessing.

E 1.6 Economic aspects

Exact treatment costs for all types of battery cannot be calculated before treatment methods have been developed.

E 1.8 Implications for national authorities

An amendment to the Statutory Order on waste is necessary to state that all batteries are to be collected when new treatment methods have been developed.

E 1.7 Implications for local authorities

In their waste management planning, local authorities will take into account the collection of all batteries when new treatment methods have been developed.

E 2 End-of-life vehicles (ELV)

| Environmental problem | Waste from end-of-life vehicles contains many environmentally harmful substances. These are especially heavy metals that today end at waste incineration plants or landfills. |

| Initiatives | Establishment of separate scheme for end-of-life vehicles.

Requirements will be laid down in a Statutory Order. Increased recycling of windscreens by development of new separation technologies. Preparation of environmental guidelines for public purchasers of vehicles. |

Objective year 2004

| 80% recycling of waste amounts | |

| environmentally safe management of harmful fractions |

E 2.1 Status

Different waste fractions are generated both before and after shredding (scrapping) of vehicles. End-of-life vehicles contain waste such as iron and metal parts, tyres, plastic, glass, oil, and other liquids.

For tyres, waste oil, and lead accumulators special schemes have been introduced, and they are described under the relevant sections of this Appendix.

After shredding, recyclable fractions such as iron, aluminium, and copper arise. The residue (shredder waste) is landfilled today (see also Section E 20).

End-of-life vehicles contain environmental contaminants, which end up in residues from incineration plants and at landfills. Management of end-of-life vehicles will be improved, ensuring increased recycling and environmentally appropriate treatment of environmentally harmful fractions.

In 1997, around 130,000 tonnes of vehicles were discarded, of which around 1,000 tonnes were hazardous waste.

A rough estimate shows that 95 per cent of waste from ELV is collected via car scrappers and similar service enterprises, and 5 per cent comes directly from industry.

Of total amounts of waste from ELV, it is assessed that around 75 per cent was recycled and around 20 per cent landfilled. The remaining 5 per cent was incinerated. The objective for year 2000 of 80 per cent recycling is to be achieved by increased recycling of tyres and windscreens85.

Various projects have been launched to develop new separation technologies with a view to recovery of glass by recycling.

Environmental guidelines have been prepared for public purchasers of vehicles.

A draft Directive on end-of-life vehicles has been tabled in the EU.

E 2.2 Future initiatives

Measures

| requirements for management of waste from ELV | |

| requirements for separation of recyclable and environmentally harmful fractions | |

| requirements for enterprises reprocessing ELV | |

| development of new technology for recycling of windscreens |

In 1999, a Statutory Order will be issued on management of end-of-life vehicles. Recyclable and environmentally harmful fractions will be separated for recycling or environmentally appropriate disposal. A certification scheme will be introduced for enterprises reprocessing ELV. Such a certification scheme will mean that waste can only be assigned to enterprises documenting that they comply with requirements stated in the Statutory Order. The requirement for a certification scheme requires an amendment to the Danish Environmental Protection Act.

Initiatives supporting the development of new separation technologies for recovery of windscreens by recycling, will be promoted. Results will be evaluated regularly. The legal base for increased recycling of windscreens will be amended as necessary.

E 2.3 Regulation

Management of end-of-life vehicles is regulated in overall rules in the Statutory Order on waste and in environmental approvals of enterprises shredding and scrapping vehicles.

E 2.4 Capacity

Today, around 350-400 enterprises exist for the reprocessing of end-of-life vehicles. Of these, five are shredder enterprises.

The planned Statutory Order on management of waste from end-of-life vehicles will have an impact on the number of dismantling enterprises which is expected to drop to some 100-150 enterprises.

Capacity is not expected to present an obstacle to achieving new objectives for recycling.

E 2.5 Environmental assessment

It is expected that the planned Statutory Order on management of end-of-life vehicles will lead to:

| dismantling of 3,500 tonnes of tyres for recycling | |

| separation of 25 tonnes of lead for recycling | |

| drawing-off of around 400 tonnes of waste oil | |

| drawing-off of around 400 tonnes of other liquids |

Within two to three years, the development of new separation technologies for recycling of windscreens is expected to lead to requirements for dismantling and recovery of glass. Around 2,000 tonnes of windscreens per year will presumably be recycled.

E 2.6 Economic aspects

The implementation of the Statutory Order on management of end-of-life vehicles is expected to lead to additional costs for consumers of DKK 30-40 million.

Consumers normally pay today DKK 300-400 per scrapped end-of-life vehicle. The future scrapping price is expected to be DKK 600-700 per vehicle.

E 2.7 Implications for national authorities

A Statutory Order on management of end-of-life vehicles will be issued.

E 2.8 Implications for local authorities

In their waste management plans, local authorities will ensure assignment of waste to plants complying with requirements of the Statutory Order for management of end-of-life vehicles.

E 3 Tyres

| Environmental problem | Tyres constitute an important resource which is not recovered to a satisfactory extent today. |

| Initiatives | The existing tyre collection scheme to be extended to

cover large tyres. Development of new possibilities of recycling for rubber powder. Preparation of environmental guidelines for public purchasers of tyres. Information campaign to be launched on limitation of damage in fitting, and promotion of sale of retreaded tyres. |

E 3.1 Status

Objective year 2004

| 80 % recycling or incineration of all discarded tyres |

Tyres contain rubber, steel, and textiles.

Waste tyres are an important resource which should be recycled or incinerated. Resource utilisation of waste tyres is not sufficient today. Until now, it has only been possible to recycle small tyres, and the objective for 1997 for recycling of such tyres has been achieved86. The objective before year 2004 is recycling or incineration of 80 per cent of all discarded tyres.

In 1997, waste tyres amounted to around 40,000 tonnes, of which around 25,000 tonnes were recycled. The remaining part was incinerated or landfilled87. Around 40 per cent of total amounts of tyres is assessed to derive from private consumers, and 60 per cent is assessed to come from industry and commerce. It is furthermore believed that the major part of tyres is disposed of via the service sector.

Studies on recycling of rubber powder have been started.

E 3.2 Future initiatives

Measures

| requirement for collection and recycling/ incineration with energy recovery of large tyres | |

| development of new possibilities of recycling of rubber powder | |

| information campaigns | |

| environmental guidelines to public purchasers of tyres |

In 1999, the Statutory Order on fees and subsidies for disposal of tyres88 will be revised and sent to hearing. Requirements will be made for collection and granting of subsidies to enterprises either recycling or incinerating large tyres.

Initiatives to support the development of new recycling possibilities for rubber powder will be promoted. Legislation and objectives will be revised as necessary.

As part of the take-back agreement, the Danish Tyre Trade Environmental Foundation carries out information campaigns with the purpose of limiting damage in fitting and promoting sales of retreaded tyres.

According to the plan of action for public purchasers, environmental guidelines will be prepared in the planning period for public purchasers of tyres.

E 3.3 Regulation

On 20th February 1995, the Minister for Environment and Energy entered an agreement with the Danish Motor Trade Association, the Association of Danish Recycling Industries and municipal associations on a take-back scheme for discarded tyres.

Through the agreement it is ensured that discarded tyres are collected and recycled or incinerated, avoiding thereby landfilling and ensuring resource utilisation of waste tyres. The collection and disposal system is designed on the following prioritisation: retreading, rubber powder production, incineration.

The agreement requests enterprises selling tyres to take back a corresponding number of discarded tyres without additional costs for the consumer.

Professional collectors are required to receive all tyres from enterprises collecting or receiving discarded tyres, including municipal collection schemes, and to deliver these for recycling or incineration.

Further to the agreement, a fee was introduced on tyres89 to finance collection and treatment, administration of the scheme, and information campaigns90.

Subsidies are granted to tyre collectors that must be registered under the Danish Environmental Protection Agency. Registered enterprises must state in which municipalities tyres are collected. On certain conditions, enterprises are required to collect tyres from waste producers. The payment of subsidies for collection is effected only when tyres have been delivered to a reprocessing plant (rubber powder manufacturer).

No subsidies are granted for tyres delivered for reuse, including retreading.

An intermediary objective is that at least 80 per cent of all discarded tyres from private cars, vans, and motorbikes will be collected and recycled or incinerated before 1997. According to the agreement, 80 per cent of all discarded tyres must be recycled or incinerated before year 2000. In 1999, the rules will therefore be extended to cover large tyres.

E 3.4 Capacity

Around 40 reuse plants exist in Denmark, retreading small tyres. In addition, one recycling plant exists, manufacturing rubber powder from tyres.

It is not considered that existing plant capacity constitutes a barrier to achieving the objective for year 2004 for recycling or incineration.

E 3.5 Environmental assessment

It is expected that the amendment to the Statutory Order will lead to all tyres being covered by the fee and subsidy scheme. Thereby, at least 90 per cent of total waste tyres will be recovered through reuse, material recycling, or incineration with energy recovery.

E 3.6 Economic aspects

The costs to industry and commerce of also introducing a fee for large tyres are expected to amount to some DKK 20 million.

Costs of collection and landfilling large tyres today are DKK 14-16 million. Therefore, extra costs of the new scheme will be DKK 4 to 6 million.

E 3.7 Implications for national authorities

In the coming planning period, Statutory Order no. 799 of 4th September 1996 on fees and subsidies for disposal of tyres will be revised.

E 3.8 Implications for local authorities

Local authorities are to assign tyres to special treatment.

E 4 Waste electrical and electronic equipment

| Environmental problem |

Waste electrical and electronic equipment contains many environmentally harmful substances, especially heavy metals |

| Initiatives | Establishment of separate scheme for waste electrical and

electronic equipment. Requirements for the scheme have been laid down in a Statutory

Order. Preparation of environmental guidelines to public purchasers of electrical and electronic equipment and eco-labelling criteria for several products. Establishment of product panel for electronics. Better resource utilisation by development of new technologies for reprocessing of products. |

Objective year 2004

| increased recycling of resources from waste electrical and electronic equipment | |

| avoid delivery to waste incineration plants and landfills of waste electrical and electronic equipment | |

| environmentally safe disposal of waste electrical and electronic equipment |

E 4.1 Status

Electrical and electronic equipment primarily covers radio and television equipment, IT products, regulation and monitoring equipment, white goods, and office equipment.

A special scheme for the treatment of refrigeration equipment exists, see Section E 11.

Management of waste electrical and electronic equipment will be improved. Products are managed today in the conventional waste management system and account for a large part of environmental contaminants ending up in residues and landfills. Recycling of waste electrical and electronic equipment's contents of metals, glass etc. will be increased, and as far as possible this waste fraction will be kept away from incineration plants and landfills. Mass flow analyses for copper and lead show that 60 per cent of copper and 40 per cent of lead going to landfills and incineration plants derives from waste electrical and electronic equipment.

Total amounts of waste electrical and electronic equipment, with a deduction of refrigeration equipment, which is discussed in Section E 11, have been calculated at 103,000 tonnes in 199791. The largest part is assessed to come from municipal bulky waste schemes (48 per cent). The remaining part is assumed to come from domestic waste (15 per cent), from institutions, trade and offices, the service sector (20 per cent), and industry (15 per cent). The remaining 2 per cent comes from the building and construction sector. Around 6,000 tonnes electronic equipment were subjected to special treatment in 1997, and 60,000 tonnes electrical equipment were mainly led to shredder plants. Against this background, it is assessed that around 30,000 tonnes were recycled in 1997, corresponding to around 30 per cent of calculated amounts of waste electrical and electronic equipment.

A Directive on disposal and reprocessing of waste electrical and electronic equipment is expected to be presented in the EU in 1999.

E 4.2 Future initiatives

Measures

| requirements for management and disposal of waste electrical and electronic equipment | |

| environmental guidelines to public purchasers of electronic office equipment | |

| establishment of product panel | |

| development of improved reprocessing methods |

In 1998, a Statutory Order on management of waste from electrical and electronic products was issued92. It is required that such waste is treated in an environmentally appropriate manner.

Further to the plan of action for public purchasers, guidelines were prepared in 1998 for public purchasers on a number of electronic office equipment, and eco-labelling criteria will be prepared for several products.

The integrated product policy will improve products by considering waste management already in the design of products. A product panel for electronics will be established in 1999.

Development of new technologies for reprocessing waste electrical and electronic equipment will be evaluated regularly. If there is a need for amending rules and regulations with a view to using best available technology, this will be done currently.

E 4.3 Regulation

Management of waste electrical and electronic equipment has so far been regulated in general rules in the Statutory Order on waste, the Statutory Order on management of waste from electrical and electronic products, and through environmental approvals of enterprises managing, reprocessing or disposing of this waste fraction.

E 4.4 Capacity

Of total amounts of electronic equipment, it is assessed that a further 20,000-30,000 tonnes will be collected and treated separately.

Around ten disassembly enterprises exist today.

Present capacity is around 12,000 tonnes per year, but the industry has stated that there will be no capacity problems in future.

E 4.5 Environmental assessment

Separate treatment of waste electrical and electronic equipment will increase recycling of heavy metals contained in the products. The possibility of recycling slag from incineration plants will also be improved.

It is expected that the Statutory Order on management of waste from electrical and electronic products will shift around 25,000 tonnes of electronics from waste incineration and landfilling to recycling. This corresponds to 40 per cent of copper landfilled today.

The integrated product policy is expected at the same time to lead to products more suitable for recycling and products containing less environmental contaminants.

E 4.6 Economic aspects

Total costs of reprocessing waste electrical and electronic equipment are calculated at DKK 100-200 million/year. It is assessed that the Statutory Order will lead to an increase in the annual waste collection fee for households of some DKK 40. For enterprises and institutions, the costs of managing 10-15,000 tonnes of electronic products will amount to some DKK 5,000/tonne compared to present costs of maximum DKK 800/tonne.

The purchase price of a television set or a computer is today from DKK 2,000 to DKK 10,000. Costs of disposal with today's requirements amount to DKK 10 to 20 per unit. Further to the new requirements, costs of disposal will increase to DKK 100 to 200. It is seen that costs of disposal will still constitute a small proportion of the purchase price.

E 4.7 Implications for local authorities

Local authorities will ensure that waste electrical and electronic equipment is collected and assigned to separate treatment at approved enterprises.

E 5 Packaging waste

| Environmental problem | Packaging waste contains large quantities of reuseable packages and recyclable materials. When environmental and economic considerations make it feasible, packaging waste is to be recycled instead of incinerated. |

| Initiatives | Citizens will have the opportunity to separate cardboard

packaging, for example via bulky waste schemes. It will be studied how collection of plastic drums from households can be organised. Glass collection will be improved. |

E 5.1 Status

Objectives year 2001

| cardboard/paper packaging - 55% recycling in year 2001 | |

| plastic packaging - 15% recycling in year 2001 | |

| metal packaging - 15% recycling in year 2001 | |

| glass packaging - 65% recycling in year 2001 |

Contrary to many other countries, Denmark has chosen not to establish one separate management system for all packaging waste. Instead, focus is put on how best to utilise various recyclable materials in waste from different sectors - and this also applies to packaging waste.

Packaging waste covers many different waste fractions such as glass, paper and cardboard, and plastic. Fractions are also discussed in separate sections in this Appendix.

As a general rule, it has been chosen not to include sales packaging of paper and cardboard, metal and plastic in recycling systems. Considering environmental economics and occupational environment and health aspects, such sales packaging is thought to be less suitable for material recycling than transport packaging. This is partly due to the fact that a fraction of, for example, plastic packaging from households will contain different types of plastic, and that the fraction will typically be contaminated with residues of foodstuffs, detergents, and similar.

The objective for material recycling of paper and cardboard is primarily achieved by recycling transport packaging from industry and commerce, in accordance with the voluntary agreement on recycling of transport packaging which was made in 1994 between the Minister for Environment and Energy and the Confederation of Danish Industries, the Danish Plastics Federation, and the Packaging Industry. In 1996, the rate of recycling for transport packaging of paper and cardboard amounted to 66 per cent.

The objective for plastic packaging is also expected to be primarily achieved through transport packaging from industry and commerce.

Material recovery of metal packaging covers recycling of steel drums from industry and commerce, as well as recycling metal scrap from incineration plants which arises from incineration of, among others, domestic waste.

Material recycling of glass packaging is done partly by recycling end-of-life beer and soft drink bottles, partly by recycling bottles for wine and spirits, as well as packaging glass collected in municipal schemes. The objective for recycling of glass packaging in year 2001 is set at 65 per cent93.

On the basis of national objectives for each packaging fraction, it is expected that total recycling of packaging waste will be around 45 per cent. National objectives for recycling of packaging waste will be revised no later than year 2000.

By far the major part of remaining packaging waste is incinerated with energy recovery. On the basis of launched and planned initiatives in packaging waste management and waste management as a whole, including the ban on landfilling of waste suitable for incineration, it is expected that total recovery of packaging waste will exceed 80 per cent.

Specific Danish initiatives for prevention of packaging waste and reuse of packages are described in Appendix A 2.3 on specific requirements for packaging and packaging waste.

E 5.2 Future initiatives

Measures

| increased recycling of cardboard packaging | |

| study of possibilities of recycling plastic drums | |

| more efficient glass collection |

In future, citizens will have the opportunity to separate cardboard packaging for recycling, for example via bulky waste schemes.

It will be studied how best to design a bring scheme for plastic bottles and drums from households.

An information campaign will be launched to increase glass collection from households. Studies have shown that many citizens are not aware that municipal glass collection schemes cover other packaging glass than bottles for wine and spirits.

E 5.3 Regulation

Rules on management and recovery of packaging waste are included in Statutory Order on waste no. 299 of 30th April 1997.

Requirements for manufacture and composition of packaging are laid down in Statutory Order on certain requirements for packaging no. 298 of 30th April 1997.

Requirements for packaging for beverages are laid down in Statutory Order on packaging for beer and soft drinks, no. 124 of 27th February 1989, with subsequent amendments.

E 5.4 Capacity, environmental assessment and economic aspects

Reference is made to sections on plastic, paper and cardboard, and glass.

E 5.5 Implications for local authorities

Further to the Statutory Order on waste local authorities must, in their waste management planning, give a statement of initiatives for prevention and recycling of packaging waste.

E 6 Hazardous waste

| Environmental problem | By definition, hazardous waste implies risk of fire, health or environmental risks, and it must therefore be managed in an environmentally safe way |

| Initiatives | Preparation of guidelines on hazardous waste Improvement of criteria for hazardous waste (environmental risk) Study of waste tax exemption for hazardous waste |

E 6.1 Status

Objective year 2004

| efficient collection of hazardous waste | |

| increased recycling of hazardous waste |

Hazardous waste is waste which is highly inflammable or constitutes a risk for health or the environment. Rules for hazardous waste are regulated in the EU and are developed regularly.

Amounts of hazardous waste in 1997 were around 1.5 per cent of total waste amounts.94.

Hazardous waste covers many different waste fractions and is generated in all sectors (see table below).

Some fractions are described separately in this Appendix: batteries and accumulators, health-care risk waste, PCB/PCT, and waste oil. For these fractions, separate schemes have been established.

The remaining part of hazardous waste is mainly treated by destruction or landfilling at Kommunekemi A/S.

In addition, some residues from waste incineration plants are classified as hazardous waste, viz. filter dust and flue gas cleaning products. These fractions are discussed separately in Section E18 of this Appendix.

| Hazardous waste 1997 (tonnes) | Repro- cessing |

Incine- ration |

Special treatment | Landfilling | Total |

| Primary sources | |||||

| -Lead batteries1 | 14,448 |

447 |

14,895 |

||

| -Hermetically sealed Ni-Cd accumulators8 | 95 |

120 |

|||

| -Waste oil led to district heating plants2 | 22,576 |

22,576 |

|||

| -Oil/chemical waste led to Kommunekemi3 and 7 | 74,215 |

74,215 |

|||

| -Dust emitting ssbestos3 | 7,000 |

7,000 |

|||

| -Hospital waste3 and 4 | 5,900 |

2,900 |

8,800 |

||

| -Sulphuric acid (coal-fired power plants)5 | 8,000 |

8,000 |

|||

| -Oil and chemical waste from other primary sources3 | 28,600 |

9,500 |

5,400 |

3,000 |

46,500 |

| Total primary sources | 51,143 |

38,423 |

82,515 |

10,000 |

182,106 |

| - in per cent | 28 % |

21 % |

45 % |

6 % |

|

| Secondary sources | |||||

| - Flue gas filter dust1 | 10,137 |

10,137 |

|||

| -Fly ash and flue gas cleaning products from waste incineration plants3,6 | 24,600 |

36,700 |

61,300 |

||

| Total secondary sources | 10,137 | 24,600 |

36,700 |

71,437 |

|

| Overall total | 61,727 |

37,976 |

107,115 |

46,700 |

253,543 |

Sources: (1) Registrations under the EU regulation on shipments of waste, (2) Subsidies granted for disposal of waste oil, (3) ISAG reporting 1997, (4) Odense University Hospital, but only for 1995, (5) Elsam, (6) Figure under special treatment means that waste is in storage, (7) Kommunekemi A/S, (8) Calculations from Danish Environmental Protection Agency. Differences between total amounts of waste hermetically sealed Ni-Cd accumulators (120 tonnes) and amounts collected for recycling reflect the fact that batteries are not collected separately, but included in general waste collection.

In addition to waste incineration plants, Kommunekemi also generates residues. These residues are also classified as hazardous waste, see Table below.

Hazardous waste from Kommunekemi

| Hazardous waste | 1997 tonnes |

1998 tonnes |

| Ash1) Slag2) Gypsum3) |

8.380(30) 10,910 970 |

5.910(80) 11,040 1,150 |

| Total | 20,260 |

18,100 |

1) Reduction in amounts of ash from 1997 to 1998 is due to reduced operation in

1998 because of renovation of flue gas system in F4. Figures in brackets state the

calculated part of thermal treatment of soil etc. in F1

2) Only part from treatment of hazardous waste in F3 and F4

3) Gypsum is generated only in the thermal treatment of contaminated soil etc. in

F1.

Criteria for hazardous waste are laid down in the EU Directive on hazardous waste95 and are based on the European Waste Catalogue96.

Like many other EU Member States, Denmark has supplemented the national list of hazardous waste with more fractions than those stated on the European list of hazardous waste.

National proposals for improvement of the European list of hazardous waste are being negotiated in the European Commission. In parallel, rules on hazardous waste are being interpreted regularly.

In 1998, a development project was launched in co-operation between the Nordic countries, the European Commission, and France with the purpose of developing criteria for the property "environmental risk".

As a consequence of new criteria for hazardous waste, requirements for reporting hazardous waste to the ISAG have been extended, so that the Danish Environmental Protection Agency in future will collect much more detailed information on hazardous waste.

A need has been seen among enterprises and local authorities to clarify rules for hazardous waste and to have a guideline on environmentally correct management of hazardous waste.

E 6.2 Future initiatives

Measures

| guidelines on hazardous waste | |

| development of new treatment methods |

In 1999, guidelines on hazardous waste will be prepared. The purpose is to enhance understanding of how to apply hazardous waste criteria.

The basis for the tax exemption for hazardous waste will be re-evaluated.

Initiatives for recycling hazardous waste such as flue gas cleaning products, will be promoted.

E 6.3 Regulation

Hazardous waste is regulated in the Statutory Order on waste97. Rules for hazardous waste were incorporated in Danish legislation in 1996.

Enterprises are responsible for assessing whether waste is hazardous, and they must notify local authorities thereof.

Local authorities must collect all hazardous waste.

E 6.4 Capacity

28 per cent of hazardous waste is recycled today:

| lead accumulators and Ni-Cd batteries are collected and sent for reprocessing in Sweden or France | |

| sulphuric acid is exported for recycling | |

| waste from photographic industry is recycled in Great Britain |

21 per cent is incinerated:

| waste oil is treated at district heating plants and at Kommunekemi A/S | |

| health-care risk waste is treated at SWS (Special Waste System) and at seven conventional waste incineration plants | |

| oily sludges are treated at Ålborg Portland |

45 per cent is subjected to special treatment:

| oil and chemical waste is primarily treated at Kommunekemi A/S. A small fraction of laboratory waste is treated at Special Waste System. |

6 per cent is landfilled:

| asbestos and contaminated soil is deposited at special landfills. |

A number of enterprises have been established, pre-treating hazardous waste, for example by separating non-hazardous fractions from hazardous waste (oil filters, paint drums, water components in waste oil). Hazardous fractions are mainly delivered to Kommunekemi A/S or to district heating plants (waste oil).

For a few waste fractions (silver from the photographic industry, organic solvents) recycling enterprises exist (recovery of silver, cooling liquids), but generally only few treatment methods have been developed, for example, for recovery or recycling of hazardous waste fractions.

Filter dust and flue gas cleaning products from waste incineration plants account for around 30 per cent of total hazardous waste amounts.

These residues are today sent abroad for landfilling. Initiatives have been launched to establish three landfills receiving stabilised flue gas cleaning products from the whole country. When the sites have been established and stabilisation methods are operational, residues will be deposited at these landfills.

E 6.5 Environmental assessment

Improved collection of hazardous waste will ensure environmentally appropriate management of this waste.

E 6.6 Implications for national authorities

Guidelines on hazardous waste will be prepared.

E 6.7 Implications for local authorities

Local authorities will inform citizens on municipal schemes for hazardous waste.

E 7 Glass

| Environmental problem | Recycling of glass and reuse of refillable glass bottles reduce energy consumption compared to manufacture of new glass. Raw materials (glass) are thereby utilised several times. Collection of glass for recycling must therefore be increased |

| Initiatives | Maintaining a return bottle system. Launching an information campaign in particular aimed at increased collection of packaging glass. Evaluate the market for wine bottle reuse. Start development work with the purpose of improving collection equipment and reducing rate of cullets. Information to local authorities on colour separation. |

E 7.1 Status

Objective year 2004

| 75% recycling of glass |

Recycling of glass leads to a reduction of energy consumption in the manufacture of new glass. Furthermore, raw materials (glass) are utilised several times. Collection of bottles and packaging glass for recycling must therefore be improved.

Total amounts of waste glass in 1997 were 190,000 tonnes. Of these, 115,000 tonnes glass were collected separately 98(bottles and packaging glass), corresponding to a collection rate of 61 per cent. Bottles are collected in municipal schemes (60 per cent), by retailers and wholesalers (32 per cent), and from restaurants, bars and cafés (8 per cent).

Separate collection will be increased through enhanced information efforts directed at citizens. Studies show that one quarter of the population is not aware that packaging glass may be delivered for recycling under present schemes. This means that only a minor part of packaging glass is collected compared to bottles. Incorrect separation is also taking place, as one fifth of the population does not know that ceramics, stoneware, and chinaware are not to be delivered together with recyclable glass.

Recycling of whole bottles may also be increased through the development of collection equipment reducing the rate of cullets. Recycling of cullets may be increased by improving colour separation of cullets.

Measures

| maintaining return bottle system | |

| information campaign on increased collection of packaging glass | |

| study of market for reuse of bottles | |

| study of reduced rate of cullets by use of better collection equipment | |

| information to local authorities on colour separation |

E 7.2 Future initiatives

A return bottle system for packaging for beer and soft drinks is one of the key elements in the achievement of the Government's objective for waste minimisation. The system ensures reuse of packaging and thereby a considerable reduction of both waste arisings and resource consumption99. A return bottle system will be maintained.

In 1999, the Danish Environmental Protection Agency will evaluate the Daish market for bottles for reuse and assess environmental impacts from export of bottles for reuse abroad.

On the basis of this evaluation, development work will be launched aimed at reducing the rate of cullets in collection through further development of collection equipment.

In year 2000, an information campaign will be launched aimed at increasing collection of packaging glass from households and relevant enterprises. The campaign will also aim at reducing incorrect separation in the form of, for example, delivery of ceramics, stoneware, and chinaware together with recyclable glass.

In year 2000, information will be distributed to local authorities on the possibilities of colour separating glass, so that the rate of discarded glass is reduced.

E 7.3 Regulation

Local councils are under an obligation100 to establish collection of glass from built-up areas with more than 2,000 households. Collection will be designed so that significant parts of glass are recycled. In most municipalities, bring-schemes have been introduced with glass banks located at central places in the area, and at recycling centres. Citizens have the duty to use collection schemes as described in municipal waste regulations.

E 7.4 Capacity

It is expected that recycling industries are able to receive increasing amounts of recyclable glass.

E 7.5 Environmental assessment

Increased colour separation and reduced rate of cullets will bring down raw material and energy consumption in the manufacture of new glass. Reduction of the rate of cullets may lead to increased reuse of whole bottles, ensuring a significant reduction of energy consumption. Reuse only requires around 15 per cent of the energy needed to produce a new bottle.

Amounts of domestic waste for incineration will be reduced, which will bring down slag amounts from incineration plants.

E 7.6 Economic aspects

Increased collection of glass packaging is not thought to have an effect on waste collection fees.

E 7.7 Implications for national authorities

An information campaign will be launched to increase collection of packaging glass and reduce incorrect separation. Information will be distributed to local authorities on colour separation. A study will be carried out on the possibilities of reducing the rate of cullets by use of better collection equipment.

E 7.8 Implications for local authorities

Local authorities will participate in the information campaign to increase collection of glass for recycling. Furthermore, local authorities will assess possibilities of increased collection and recycling by more frequent collections and more dense location of glass banks.

Local authorities must take into consideration information to be distributed in year 2000 on the possibilities for colour separation of glass, thereby reducing the rate of discarded glass.

E 8 Impregnated wood

| Environmental problem |

Impregnated wood contains a number of environmental contaminants which cause problems in the disposal. The amount of waste impregnated wood is increasing. |

| Initiatives | It will be ensured that impregnated wood is managed as

waste not suitable for incineration. Incineration of creosote-treated wood may be

authorised. When suitable treatment methods for impregnated wood have been developed, it will be collected and treated separately. |

Objective year 2004

| utilise energy and raw material resources in waste impregnated wood |

E 8.1 Status

Impregnated wood is treated with impregnators containing, for example, chromium, copper, arsenic (CCA), tin, and creosote.

Impregnated wood containing heavy metals causes problems in incineration, as substances are not decomposed but remain in slag and flue gas waste.

Creosote-treated wood (for example sleepers, wood from wharfs) can be decomposed in incineration, as creosote is destroyed. This requires, however, that such wood is pre-treated (crushed), ensuring complete incineration, and that the incineration temperature is sufficiently high.

Sources of waste impregnated wood are primarily bulky waste and the building and construction sector. Impregnated wood is mostly disposed of today by landfilling, but small amounts of impregnated wood are incinerated.

New and better treatment methods are being developed, allowing for utilisation of resources contained in impregnated wood (energy, chromium, cobber, arsenic).

In the coming years, increasing amounts of waste impregnated wood are expected. It is assessed that since the 60s, around 2.7 million tonnes impregnated wood have been used (accumulated), and that in year 2010 it will be necessary to dispose of some 100,000 tonnes impregnated wood101.

E 8.2 Future initiatives

Measures

| rules for the treatment of impregnated wood | |

| development of new methods to treat waste impregnated wood |

In 1999, it will be ensured that impregnated wood is separated as waste not suitable for incineration.

Rules for the treatment of creosote-treated wood will be prepared in 1999. Initiatives for the development of methods to destroy creosote-treated wood completely, and to recover heavy metals from impregnators will be promoted.

When new treatment methods have been developed, all impregnated wood will be collected and treated separately. Until then, impregnated wood is to be landfilled.

E 8.3 Regulation

Management of impregnated wood is regulated today in general waste regulations. This means that local councils must assign disposal possibilities for impregnated wood.

E 8.4 Environmental assessment

Impregnated wood is today disposed of by both incineration and landfilling. By avoiding impregnated wood at incineration plants, heavy metal contents in slag and flue gas cleaning waste will be reduced.

Some 50,000 tonnes of separated impregnated wood are expected in year 2004.

E 8.5 Economic aspects

In the next few years, no considerable extra costs of disposal of impregnated wood are expected. At present, it is not possible to assess treatment costs in new treatment technologies.

E 8.6 Implications for national authorities

The Statutory Order on waste will be revised to include a ban on assignment of heavy metal-containing impregnated wood to incineration.

E 8.7 Implications for local authorities

In their planning, local authorities will take into consideration that impregnated wood may not be incinerated. They will also plan for separate treatment when suitable treatment methods have been developed.

E 9 Health-care risk waste

| Environmental problem | Health-care risk waste is infectious. |

| Initiatives | No new initiatives |

E 9.1 Status

Objective year 2004

| status quo |

Health-care risk waste is generated in both the primary and the secondary health sectors. The characteristic feature of health-care risk waste is that it may be infectious by direct contact.

According to the ISAG, 8,800 tonnes of health-care risk waste were generated in 1997.

Due to its infectious nature, health-care risk waste is classified as hazardous waste102.

Almost all health-care risk waste is generated in the service sector.

Waste is incinerated both at special incineration plants and at conventional plants in compliance with special conditions reducing the risk of contact with waste. From an environmental point of view, the incineration process is similar to incineration of, for example, domestic waste. Incineration leads to inactivation of waste, energy recovery, reduction in volume and unrecognisability, which is preferable, especially for tissue waste.

Disposal requires a relatively large amount of packaging. To the extent that improved separation will reduce amounts of health-care risk waste, it will indirectly reduce overall waste amounts, as packaging needs would be reduced correspondingly.

A guideline on health-care risk waste was issued in 1998103.

The European Commission has informed that by the end of 1998, initiatives will be taken to discuss definitions and requirements of management of health-care risk waste. This may be in the form of a proposal for a Directive.

E 9.2 Future initiatives

No new initiatives are envisaged for health-care risk waste.

E 9.3 Regulation.

Health-care risk waste management is regulated in the Statutory Order on waste. Health-care risk waste is classified as hazardous waste, and under the terms of the Statutory Order on waste, local councils must therefore establish collection schemes for such waste.

E 9.4 Capacity

Disposal of health-care risk waste takes place at one special plant and seven conventional waste incineration plants.

E 9.5 Implications for national authorities

None - if an EU directive is adopted, it will have implications for national authorities.

E 9.6 Implications for local authorities

None.

E 10 Sludge from municipal wastewater treatment

| Environmental problem | Sewage sludge is a resource that is not utilised sufficiently today |

| Initiatives | Re-evaluation of present rules for application of sludge to farmland |

E 10.1 Status

Objective year 2004

| 50% recycling on farmland | |

| 30% incineration | |

| 20% landfilling | |

| increased utilisation of both fertiliser and energy contents in sludge by recycling |

The contents of both fertiliser and energy in sewage sludge may be utilised in recycling. Today, it is often only the fertiliser content that is recovered, as sewage sludge is applied directly to farmland due to the content of nutrients, especially phosphorus.

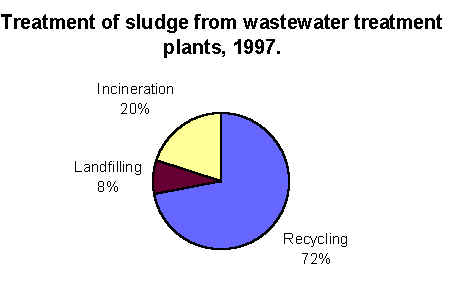

In 1997, around 1,209,000 tonnes sludge (wet weight) were generated at municipal wastewater treatment plants. Of this, 72 per cent was recycled, fulfilling the Government's objective for 50 per cent recycling in year 2000. 20 per cent was incinerated and 8 per cent landfilled.

Requirements for the content of certain chemical substances in sludge, which took effect in 1997 will become stricter in year 2000104, and this means that in a transitional period alternatives to application to farmland must be found.

The present high rate of application of sludge to farmland is not expected to be upheld. The objective is therefore 50 per cent recycling in year 2004. It is expected that 30 per cent will be incinerated and 20 per cent landfilled in year 2004.

The quality of sludge and possibilities of increased recycling are expected to improve by reducing the use of xenobiotic substances. The contents in sludge of certain of the chemical substances for which limit and cut-off values have been introduced, are therefore expected to be reduced in the long term.

A number of studies have been launched in order to assess regularly requirements in connection with recycling sludge. The studies deal with assessment of decomposition of xenobiotic substances in sludge by different forms of treatment, long term effects of application of sludge to farmland, and the assimilation in plants of xenobiotic substances.

E 10.2 Future initiatives

Measures

| re-evaluation of current rules | |

| study of biogasification of sludge |

In the study programme for biogas, funds will be provided for detailed studies of biogasification of sludge prior to application to farmland. The intention is that as much sewage sludge as possible will be subjected to biogasification in the long term.

Against the background of results from studies and evaluations, it will be considered to revise rules for application of sewage sludge to farmland.

In late 1999, the Danish Environmental Protection Agency will prepare a status report for recycling of organic domestic waste and sewage sludge. This will be done on the basis of, partly, results of ongoing studies. This status report will form the basis for a plan of action for recycling organic waste.

E 10.3 Regulation

Application of sludge to farmland is regulated in the Statutory Order on sludge105, and the Statutory Order of the Ministry of Food, Agriculture and Fisheries on inspection of the quality of municipal sewage sludge and composted household waste applied to farmland106. The Statutory Order on sludge lays down limit values for a number of heavy metals and cut-off values for organic xenobiotic substances NPE, DEHP, LAS, and certain PAHs. Cut-off values for organic substances took effect on 1st July 1997 and will, together with limit values for cadmium, become stricter as per 1st July 2000.

E 10.4 Capacity

Capacity for treatment of sludge at biogas plants is expected to increase. In year 2004 these plants are expected to be able to treat 100,000 tonnes of sludge (wet weight).

E 10.5 Environmental assessment

In biogasification, the energy contents of sludge are utilised. For example, biogasification of 100,000 tonnes of sludge will generate energy in the range of 100-150 TJ. The process is evaluated not to degrade the fertiliser potential of sludge, but on the contrary, in some cases to improve this potential.

E 10.6 Implications for national authorities

If an evaluation shows it necessary, the Statutory Order on sludge may be revised.

In the end of 1999, a status for recycling of organic domestic waste and sewage sludge will be prepared.

E 10.7 Implications for local authorities

Local authorities will investigate possibilities of biogasification of sewage sludge, for example by contacting centralised biogas plants, co-digesting manure and organic waste, and will find alternatives to application to farmland, in cases where limit values and cut-off values cannot be complied with.

E 11 Refrigeration equipment

| Environmental problem | Refrigeration equipment contains environmentally harmful fractions, especially heavy metals and CFCs |

| Initiatives | Maintaining existing scheme |

E 11.1 Status

Objective year 2004

| 90% collection of total number of discarded products |

Refrigeration equipment contains CFCs and other environmentally harmful fractions. Refrigeration equipment must be managed in an environment-friendly way, and separation of environmental contaminants for separate treatment must be ensured. Furthermore, separation of recyclable fractions (iron and metal parts) must be ensured.

For waste electrical and electronic equipment a special scheme exists (see Appendix E 4).

Total amounts of waste refrigeration equipment were around 15,000 tonnes in 1997. It is estimated that 12,500 tonnes of refrigeration equipment were collected in 1997, corresponding to 83 per cent of the potential.

80 per cent of waste refrigeration equipment is collected in municipal bulky waste schemes, and 15 per cent derives from institutions, trade and offices. The remaining 5 per cent is collected from industry.

E 11.2 Future initiatives

No new Danish initiatives for refrigeration equipment are planned in the coming planning period. The existing scheme will be maintained.

E 11.3 Regulation

Collection and management of CFC-containing refrigeration equipment is ensured by an agreement between the Minister for Environment and Energy and relevant associations on the disposal of CFC-containing refrigeration equipment, as well as in a Circular107 on municipal regulations on disposal of CFC-containing refrigeration equipment.

The objective of the agreement is to collect a minimum of 90 per cent of the total amount of discarded refrigeration equipment for treatment, in compliance with requirements laid down in the Circular.

The Circular states that local councils are under an obligation to establish assignment or collection schemes for discarded CFC-containing refrigeration equipment and certain waste fractions.

At least 95 per cent of the content of the cooling agent CFC-12 must be extracted and collected. The frothing agent CFC-11 must be extracted at a rate of at last 80 per cent. Extracted CFC-12 must either be recycled or disposed of . CFC-11 must be disposed of.

In municipal regulations, rules are laid down for processing of refrigeration equipment, ensuring resource recovery of recyclable waste fractions.

The Circular also states that rules should be laid down for removal of mercury switches and condensers (PCB), see Section E15.

E 11.4 Capacity

Around five enterprises exist that extract CFCs from refrigeration equipment.

E 11.5 Environmental assessment

It is estimated that around 250,000 pieces of refrigeration equipment (corresponding to some 12,500 tons) are managed in compliance with the Circular, and that around 100 tonnes CFCs are extracted and destroyed in an environmentally appropriate manner.

E 11.6 Implications for national authorities

None.

E 11.7 Implications for local authorities

Local authorities are to establish assignment or collection schemes for discarded refrigeration equipment, and environmentally correct treatment should be ensured.

E 12 Organic domestic waste

| Environmental problem |

Organic domestic waste is a resource that is not utilised sufficiently today. |

| Initiatives | Launching of full-scale tests with collection and

biogasification of organic domestic waste. Study of optimised collection and biogasification of organic domestic waste. Requirement for mandatory collection when experience from biogasification allows it. Preparation of status for recycling of organic domestic waste and wastewater sludge. |

E 12.1 Status

Organic domestic waste is a resource which is not utilised sufficiently today in composting or biogasification.

Biogasification is the highest priority treatment form for organic domestic waste, as both energy and fertiliser contents of waste are recovered. Composting, including home composting, is still a suitable form of treatment to utilise the fertiliser contents of waste.

Organic domestic waste is both vegetable and animal food waste, and other putrescible organic material. Organic waste accounts in general for 40-45 per cent of total domestic waste108. In 1997, around 70,000 tonnes of domestic waste were recycled in biological treatment109, corresponding to some 4 per cent of domestic waste.

Residues from biological treatment of organic domestic waste must comply with the same requirements as sewage sludge from municipal waste water treatment plants with respect to contents of heavy metals and xenobiotic substances in relation to application to farmland (see also Appendix E 10).

On the basis of contents of heavy metals and xenobiotic substances, it is evaluated that in general there will be no problems with biological residues and their compliance with limit and cut-off values. A number of studies, including studies on the effects of composting and biogasification processes on the decomposition of xenobiotic organic substances, have been launched.

Objective year 2004

| recycling of organic domestic waste corresponding to 7% of total domestic waste amounts | |

| 100,000 tons recycled by biogasification |

Long term objective

| recycling of organic domestic waste corresponding to 20-25% of total domestic waste amounts |

Recycling is today far from the objective for year 2000110. This is primarily due to the fact that mandatory dual collection of organic waste and residual waste, allowing composting and biogasification, has not been introduced, for organisational and technical reasons.

Positive experience has been gained with treatment of organic domestic waste at biogas plants based on manure, and at a plant for co-digestion of sludge and organic domestic waste. However, more experience is needed, and technologies shall be better documented.

The objective is to recycle a total of 150,000 tonnes of organic domestic waste, corresponding to 7 per cent of total amounts of domestic waste in year 2004. Longer term objectives are still to recycle organic domestic waste corresponding to 20-25 per cent of total domestic waste amounts.

E 12.2 Future initiatives

Measures

| full-scale tests with collection and biogasification | |

| study of optimised collection and treatment | |

| requirements for mandatory collection |

It is planned to launch a full-scale pilot project to gain further documentation and demonstration of biogasification. The project will be located in a number of municipalities with collection of organic domestic waste and treatment at centralised biogas plants co-digesting manure and organic waste.

Under the Danish Energy Agency's development programme for biogas, funds will be granted to studies of optimisation of environmental and financial aspects of sorting, collection, pre-treatment, and biogasification of organic domestic waste.

In late 1999, on the basis of results from ongoing studies, the Danish Environmental Protection Agency will prepare a status report for recycling of organic domestic waste and sewage sludge. This status report will form the basis for a plan of action for recycling of organic waste.

Mandatory separate collection will be introduced when experience from biogas plants is sufficient. The expected extension of centralised biogas plants co-digesting manure and organic waste, cf. Energy 21, will be based on future experience with biogas technology. It is a prerequisite for meeting long term objectives for recycling of organic domestic waste that mandatory dual collection is introduced.

E 12.3 Regulation

Under the terms of the Statutory Order on waste no. 299 of 30th April 1997, local councils must establish collection of domestic waste from households in built-up areas accommodating permanently more than 1,000 inhabitants. In municipal regulations, local councils may permit home composting of the vegetable fraction of domestic waste.

In 1994, the Minister for Environment and Energy entered an agreement with the National Association of Local Authorities in Denmark, the City of Copenhagen, and the Municipality of Frederiksberg on organic waste. It was established that biogasification of organic waste is environmentally superior to alternative forms of treatment, and that a flexible solution should be chosen, supporting local initiatives for introduction of separate collection and treatment of organic domestic waste.

E 12.4 Capacity

Capacity at existing biogas plants amounts to 20,000 tonnes organic domestic waste per year, and utilisation is far from maximum. With some reconstruction of plants, capacity may be increased to 50,000 tonnes/year. According to the Government's plan of action for energy - Energy 21 - energy supply from biogas will increase from 2 PJ today to 20 PJ in year 2020111.

With some reservations, including rules from the Ministry of Food, Agriculture and Fisheries, it is assessed that in year 2004 around 100,000 tonnes of organic domestic waste may be treated at biogas plants based on manure, and thereby objectives will be achieved.

E 12.5 Economic aspects

Establishment of separate collection and biological treatment of organic fractions requires that investments are made in collection systems and treatment capacity. Calculations show that costs of total operation (including interest payment and depreciation) will not necessarily exceed costs of today's single-string system. Costs will largely depend on types of housing and chosen systems.

E 12.6 Environmental assessment

Biogasification of 100,000 tonnes of organic domestic waste will give a gain of energy of 50-100 TJ compared to incineration of the same amounts of organic domestic waste. Furthermore, the digestate from biogasification of 100,000 tonnes of organic domestic waste may replace around 780 tonnes of chemical fertilisers.

E 12.7 Implications for national authorities

Full-scale tests will be launched on collection and biogasification of organic domestic waste.

In late 1999, a status report for recycling of organic domestic waste and sewage sludge will be prepared.

E 12.8 Implications for local authorities

Local authorities should start planning new waste collection systems with source separation and separate collection of organic domestic waste. They should investigate possibilities for co-operation with existing biogas plants based on manure or establishment of new biogas plants.

E 13 Organic waste from industry and food waste from catering centres

| Environmental problem | Organic waste is a resource that should be utilised to an optimum extent. |

| Initiatives | Re-evaluation of existing scheme for food waste from catering centres. |

E 13.1 Status

Organic waste is generated both in industry and catering centres. Some waste from industry is homogeneous by-products and is therefore not included in the ISAG (Information System for Waste and Recycling, see Appendix B).

Objective year 2004

| recycling of at least 95% |

In industry, just below 8.5 million tonnes of organic waste are generated each year. This waste is biologically decomposable waste such as abattoir waste, dairy waste, fishery waste etc., often with a low content of dry matter112.

The major part is recycled. Part of this waste is used directly as fertiliser on farmland, and some waste substitutes other raw materials. The remaining tenth is subjected to biogasification113. Only around one per cent is incinerated or landfilled. It is expected that the landfilled amount will decrease, further to the ban on landfilling of waste suitable for incineration, which took effect on 1st January 1997. Overall, no disposal problems for such residues are encountered.

Food waste from catering centres114 is generally reprocessed into animal fodder and similar. Reprocessing plants estimated in 1996 that the potential for collection of food waste was between 22,000 and 30,000 tonnes/year, of which around 22,000 tonnes were reprocessed.

E 13.2 Future initiatives

Measures

| recycling of food waste from catering centres to be evaluated |

Alternative recycling possibilities for food waste from catering centres will be studied, with due respect to rules issued by the Ministry of Food, Agriculture and Fisheries.

E 13.3 Regulation

The collection scheme for food waste from catering centres is based on a Statutory Order115, according to which local authorities must establish collection of food waste from catering centres for reprocessing into fodder or similar.

E 13.4 Capacity

Due to the extension of biogas plant capacity planned under the Government's plan of action for energy, Energy 21, there is thought to be sufficient treatment capacity at biogas plants.

E 13.5 Environmental assessment

No significant changes in environmental aspects are expected.

E 13.6 Implications for national authorities

Depending on possibilities of applying alternative treatment forms for food waste, rules on collection of food waste from catering centres will be amended.

E 13.7 Implications for local authorities

Local authorities will maintain their present efforts.

E 14 Paper and cardboard

| Environmental problem | Waste paper and cardboard is a valuable resource which is not utilised sufficiently today. |

| Initiatives | Paper collection will be extended by establishment of

kerbside collection schemes from households. Householders will have the opportunity to separate cardboard for recycling, for example via bulky waste schemes. Guidelines will be prepared clarifying local authorities' responsibility for ensuring increased collection of cardboard and paper from enterprises. Possibilities for increased recycling of paper and cardboard will be studied |

E 14.1 Status

Objective year 2004

| 60% recycling of paper and cardboard from households | |

| 75 % recycling of paper and cardboard from enterprises, public and private institutions |

Paper and cardboard collection can be improved, and citizens, enterprises, public and private institutions will have an important role to play in this respect.

In 1997, 583,000 tonnes of paper and cardboard were collected, corresponding to 43 per cent of paper consumption116. The rate of collection increased steadily from 1985 to 1997.

In 1996, collection efficiency was assessed to be around 32 per cent from households, and around 63 per cent from enterprises and institutions117. Amounts of paper and cardboard suitable for recycling118are smaller in households than in all other sectors put together, which is one of the reasons for differences in collection efficiency.

E 14.2 Future initiatives

Measures

| kerbside collection of paper from households | |

| local authorities' responsibility for ensuring increased recycling of paper and cardboard from industry and commerce to be clarified | |

| guidelines on paper and cardboard collection from public and private enterprises |

Collection of paper from households will be doubled by using more efficient collection systems and collecting more types of clean paper. From year 2000, kerbside collection schemes from households are to be established. Schemes are to be introduced allowing householders to separate cardboard for recycling, for example via bulky waste schemes.

Collection of paper and cardboard from industry and commerce may be improved by enhancing local authorities' responsibility for ensuring separation. In 1999, a guideline will be prepared, clarifying responsibility for separation.

In order to limit problems and increase recycling possibilities for paper and cardboard, factors inhibiting possibilities of recycling (for example glue and inks) will be studied, and know-how on environmental aspects of paper and cardboard recycling will be updated.

E 14.3 Regulation

Rules on collection and recycling of paper and cardboard are laid down in the Statutory Order on waste119. Local councils are under an obligation to collect paper for recycling from built-up areas with more than 2,000 households. In most municipalities, bring-schemes have been established with paper banks located at central places and at recycling centres. In many housing estates, collection schemes have been introduced, and waste paper is delivered to the same place as domestic waste.

Requirements for collection of paper from households will be amended in future, and in year 2000 local councils are to establish kerbside collection schemes with permanent collection equipment.

For a number of years, local councils have been under an obligation to ensure recycling of paper and cardboard from commercial enterprises. With effect from 1st July 1998, this obligation has been extended to comprise all enterprises as well as public and private institutions.

In 1994, an agreement was made between the Ministry of Environment and the Confederation of Danish Industries, the Danish Plastics Federation and the Packaging Industry on transport packaging. The agreement set up the objective that 80 per cent of transport packaging of plastic, cardboard and paper was to be recycled before year 2000, either by reuse or material recycling.

In 1998, the agreement was adjusted so that the definition of transport packaging now follows the definition of the EU packaging Directive, and so that the objectives expressed in percentages now only apply to material recycling.

E 14.4 Capacity

Recycling capacity is sufficient in Denmark. The market for recycled paper is good both at national and international levels, but prices fluctuate greatly.

Around 20 enterprises exist in Denmark today, marketing waste paper. Five enterprises exist reprocessing waste paper into new products.

Treatment capacity is sufficient for recycling increasing waste paper amounts.

E 14.5 Environmental assessment

Recycling waste paper is environmentally superior to manufacturing new paper. Increased recycling of paper entails CO2 reduction in all countries affected by the Danish waste paper cycle. Amounts of domestic waste for incineration will also decrease, reducing capacity needs.

E 14.6 Economic aspects

The extension of paper schemes will lead to additional annual costs of around DKK 125 million, corresponding to DKK 60 - 100 per household. This is due to the fact that costs of collection systems and collection equipment are higher than for present systems.

E 14.7 Implications for national authorities

The Statutory Order on waste will be amended, stating requirements for establishment of kerbside collection schemes from year 2000.

A guideline will be prepared, clarifying rules for collection of paper and cardboard from enterprises and public and private institutions.

E 14.8 Implications for local authorities

In their future planning, local authorities will:

| establish kerbside collection of waste paper from households | |

| order private and public enterprises to separate paper and cardboard for recycling | |

| prioritise supervision and other efforts for recycling of paper and cardboard from enterprises and public and private institutions. |

E 15 PCB/PCT

| Environmental problem | PCB/PCT is hazardous to human health and the environment |

| Initiatives | No new initiatives |

E 15.1 Status

Objective year 2004

| Status quo due to objective for year 2000 to phase out PCB/PCT- bearing oils (> 0,05 per cent by weight) in transformers |

PCB is a group of polychlorinated biphenyls, and PCT is a group of polychlorinated terphenyls. Substances are heavily decomposable and accumulate in the food chain. PCBs and PCTs are mutagenic, carcinogenic and are also suspected of having hormonal effects on reptiles and mammals. High concentrations of PCBs and PCTs have been found in fat tissues of, for example, polar bears, seals, and birds of prey.

In a 1986 report from the Danish Environmental Protection Agency is was documented that PCB/PCT constitutes a risk to the environment.

PCBs and PCTs have been used as cooling and insulation liquids in electrical equipment such as transformers and condensers. They have furthermore been used in heat pumps, gas turbines, hydraulic systems, glue, fire inhibitors, sealing compounds etc.

In Denmark and internationally, special efforts have been made to phase out the use of these substances. Import and marketing of PCB/PCT as well as equipment containing these substances have been prohibited in Denmark since 31st October 1986.

Furthermore, since 1st January 1995 the use of PCB/PCT-containing condensers and equipment above a certain limit (total weight > 1 kg or effect > 2kW) has been banned. Therefore, large transformers (>5 l PCB) do not exist in Denmark. Smaller condensers and transformers may be used until the end of their useful life.