|

Alternatives to mercury-containing measuring devices 2 Thermometers other than fever thermometers

2.1 Application of mercury-containing thermometers other than fever thermometersThermometers measure temperature. Apart from fever thermometers, three types of mercury-containing thermometers were previously used in Denmark:

In Denmark, the use of thermometers other than fever thermometers is only allowed for calibration purposes and for laboratory use. Mercury thermometers may in principle be used for all types of temperature measuring for manual reading in the temperature interval above the freezing point of mercury, -39°C. The most common mercury thermometers consist of mercury encased in a thin glass tube that rises and falls with temperature. This thermometer was widely used in laboratories, as room thermometers and for temperature monitoring of machines, combustion processes and industrial processes. These types of thermometers are still allowed and marketed for use in laboratories. The mercury content was 10-20 g Hg/piece for large thermometers for boilers, whereas smaller thermometers contained 4-5 g Hg/piece (Hansen 1985). Thermometers used today in laboratories typically contain about 14 g Hg/piece corresponding to 1 ml mercury. Another type, previously used for remote control of large engines or combustion processes, consists of a sensor on the machine, an up to 40 m long mercury filled capillary connecting the sensor and the control room and a gauge consisting of a bourdon coil with a pen or needle for reading the temperature (Rasmussen 1992). The mercury content ranged from about 5 to 200 g (Maag et al. 1996). These thermometers were mainly used for marine engine purposes and within the power sector. Mercury-containing contact thermometers, in fact thermostats, were previously used for switching of a heating element in laboratories (Rasmussen 1992). When the mercury expanded in response to increased temperature, it established an electric contact between two terminals. The thermostats are electric equipment and not within the scope of the current study. A thermometer with a U-shaped tube can be used for min/max thermometers indicating minimum and maximum temperature during a period of time. Mercury-containing min/max thermometers were previously part of the equipment of type of small weather stations called "English huts" [Danish: engelsk hytte], but they have today been replaced by electronic thermometers (Dahl 2006). For long transports in e.g. refrigerated containers, insurance companies demand continuous monitoring and verification of the temperature during the whole transport (Gustafsson 1997). According to a Swedish study, in the late 1990s a manually supervised instrument containing 190 g mercury dominated the market for marine transports. The use of such instruments has not been described in Danish studies, but it may have been used. Today, automatic devices without mercury, approved by the international insurance companies for supervision of refrigerated containers, are marketed. Some standards, e.g. some German DIN standards, prescribe the use of mercury thermometers, which may be a hindrance for phasing out mercury thermometers for laboratory use. Development of revised standards would encourage mercury substitution in the laboratory sector. Advantages and drawbacks of the mercury-containing equipment Compared with glass thermometers filled with other liquids, the mercury-containing thermometers are more precise and are the only suitable liquid thermometers for measurements at 0.1 degree resolution according to Andersen (2006). Thermometers tested and certified for accurate measurements at 0.1 degree resolution are marketed at prices of about ten times the price of ordinary mercury thermometers (Thoft 2006). The disadvantage of the mercury thermometers is that the thermometers easily brake and that the toxic mercury may be spread to the laboratory environment and surroundings at the breakage. Further, by heating of the thermometers, small bubbles may be formed in the mercury column resulting in a wrong reading of the temperature. The available electronic thermometers are generally more accurate than mercury-containing thermometers, if properly calibrated. The laboratories accredited for calibration of thermometers typically use platinum resistance thermometers for calibrating other thermometers. According to Andersen (2006) from the thermometry laboratory of the Risø National Laboratory, an essential disadvantage of the electronic thermometers by normal laboratory use is that there is no visible indication, if the probe is damaged, e.g. after a drop of the thermometer onto the floor. Contrary to this, Nielsen (2006) from the national temperature reference laboratory of the Danish Technological Institute does not find any justification for the continued use of mercury thermometers in laboratories. The electronic thermometers are more accurate than the mercury-containing thermometers, but have to be calibrated more often. The electronic thermometers are typically calibrated every year, whereas mercury thermometers are typically calibrated every second year. When using the electronic thermometers it is necessary to check and recalibrate the thermometer, when it has been dropped. Nielsen (2006) finds this to be a relatively simple task compared to the clean up, when a mercury-containing thermometer is dropped. - Thermometers for engines Previous mercury consumption in Denmark In 2001, non-fever mercury thermometers were only allowed for laboratory use. Skårup et al. (2004) estimate that a total of 1,000-1,500 mercury-containing laboratory thermometers were sold during 2001. By assuming that each thermometer contains about 15 g mercury, the total content of sold thermometers was estimated at 15-23 kg/year. It has not, within the limits of the present study, been possible to obtain information allowing an updated quantification of the total sale of mercury-containing thermometers in Denmark. According to one of the main suppliers for the laboratory sector in Denmark, mercury-containing thermometers today account for about 10-15 % of the thermometers sold to the sector (Thoft 2006). Applications where mercury may be reintroduced 2.2 Alternatives for main application areasA number of different types of non-mercury thermometers are marketed, among these:

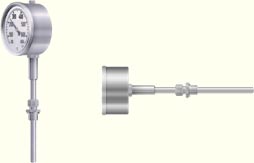

The thermocouple thermometers, platinum resistance thermometers and the infrared thermometers are all based on a thermoelectric principle and can via an analogue to digital converter be connected to a datalogger. These are sometimes jointly designated electronic thermometers or digital thermometers. Liquid-in-glass thermometers The coloured liquid thermometers for professional use are marketed by a number of suppliers in Denmark. The price is roughly the same as for mercury thermometers. According to Andersen (2006), the liquid-in-glass thermometers are not suitable for accurate measurements at 0.1 degree resolution, but the mercury-free thermometers are fully applicable for less accurate measurements. A disadvantage is that some of the liquid by heating may evaporate and condense as a colourless droplet in the top of the glass tube, which can only be observed under a magnifying glass (Andersen, 2006). The result may be that the thermometers read a half to one degree below the actual temperature. Dial thermometers The thermometers are available for measuring of temperatures in the range from about -70°C to 600°C. The dial thermometers have typically replaced mercury-in-glass thermometers for the temperature range above 250°C, e.g. for measuring the temperature of exhaust gases of diesel engines. The price for a dial thermometer for e.g. a diesel engine is reported to be about 2-4 times the price of a similar mercury thermometer (Petersen 2006; Sponholz 2006, Plesner 2006, Hau 2006). The price of e.g. a mercury-free dial thermometer for a diesel engine is about 400 DKK (53 Euro)/piece . In the marine sector, insurance contracts in Denmark prescribe that the engines are equipped with thermometers which can work without external power (Petersen 2006). The manual thermometers often serve as backup for electric thermometers with automatic reading.

A number of dial thermometers for remote measurements of the temperature in industry, power plants and marine applications are available as alternatives to mechanical mercury thermometers for remote temperature reading. The thermometer probes are either filled with gases like nitrogen, argon or helium or liquids and attached to the dial by a capillary. The price of the remote type thermometers are typically about 2-4 times the price of a similar mercury thermometer (Hau 2006).

Electronic thermometers A thermocouple works because there is temperature-dependent voltage drop across dissimilar metals, which are placed in contact. In principle, a thermocouple can be made from almost any two metals. In practice, several thermocouple types have become standard. Thermocouples types designated K, J, T, N, S, R and B can be used for application in temperature ranges from -40°C to +1800°C (Senmantic 2006). Thin-film resistance thermometers provide accuracy over a wide temperature range (from -200 to 850 °C). The principle of operation is to measure the resistance of a metal (typically platinum or nickel) element. The thermometers consist typically of either a metal coil or film surrounding a core of plastic, glass or ceramics. The most common type, designated PT100, is widely used for all types of application, where accurate automatic reading of the temperature is demanded. Standard sensors are available from many manufacturers with various accuracy specifications and numerous data logging options to suit most applications. Some types of electronic thermometers for high accuracy and resolution combine the output from more probes. Electronic thermometers are applied everywhere in the industry for automatic temperature measurements. For some applications, e.g. diesel engines for marine applications, the automatic measurements may be supplemented with mechanical thermometers for manual reading. In weather stations in Denmark, PT100 thermometers with data logging are today standard equipment (Dahl 2006; Nehring 2006). For laboratory use the electronic thermometers take up an increasing part of the market in Denmark (Thoft 2006). Thermometers with different probes are marketed for use in different media. Electronic thermometers for measurements at 0.1 decree resolution are available (Thoft 2006). PT100 type thermometers are widely used for monitoring of the temperature of foodstuffs during transport (see example below). The thermometers are e.g. approved by Det Norske Veritas (DNV), Germanischer Lloyd (GL) and Lloyd’s Register of Shipping (LRS). (http://www.kp-as.com/produktside.asp?item_id=82&action=fsp). The electronic thermometers may substitute for mercury thermometers for some applications, but the mercury thermometers cannot substitute the other way around as they are not applicable for automatic measurements. If automatic measurements are not needed, the mechanical thermometers described above are cheaper alternatives and the options of choice. The price of PT100 machine thermometers are in the order of magnitude of 10 times of a simple mercury-in-glass machine thermometer (Sponholz 2006). However, price comparisons are complicated by the fact that the electronic thermometers typically consist of two separate parts: a probe (sensor) and a datalogger. Several different probes may be used for the same data logger. Electronic thermometers for use in laboratories are marketed at a price of about ten times the price of an ordinary mercury thermometers of approximately DKK 100 (Thoft 2006). The price of tested and certified mercury thermometers, however, is approximately DKK 1,200, similar to the price of the electronic thermometers.

Infrared thermometers 2.3 SummaryAlternatives for all applications of mercury-containing thermometers are marketed in Denmark. The price of alternatives ranges from approximately the same price (liquid-in-glass thermometers) to up to ten times the price of the mercury thermometer for some electronic thermometers. The price of the electronic thermometers is not directly comparable to mercury thermometers as the electronic thermometers have the advantage of automatic measurements and data logging The liquid-in-glass thermometers can substitute for the mercury thermometers for most applications except for measurements above 250 °C or for measurements at less than 1 degree resolution. For high-temperature applications in the industry the mercury thermometers are typically replaced by dial thermometers for manual reading or electronic thermometers. For high resolution measurements the mercury thermometers are to some extent replaced by electronic thermometers, but the mercury thermometers are still widely used in laboratories, which is exempted from the current Danish ban. A barrier for phasing out mercury thermometers in laboratories is that the use of mercury thermometers is prescribed by some standards used in the laboratories. Table 2.1 Marketed alternatives for mercury-containing thermometers in Denmark

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||