Mapping, emissions and environmental and health assessment of chemical substances in artificial turf

6 Analyses

- 6.1 Analysis methods and analysis programme

- 6.2 Results of screening analyses

- 6.3 Results of leaching tests

- 6.4 Discussion of results

- 6.5 Selection of substances for health and environmental assessment

6.1 Analysis methods and analysis programme

6.1.1 Chemical screening analyses

Chemical screening analyses have been carried out for organic substances on the majority of the products collected in the form of elastic infills, artificial turf mats and pads.

The analyses for the organic components have comprised headspace analyses for emissions of volatile substances and analysis of dichloromethane extracts (DCM) for constituents in the actual products.

For a small selection of the artificial turf mats, a supplementary screening for elements has been carried out using X-ray analysis.

6.1.1.1 Semi-quantitative GC/MS headspace screening for emission of volatile organic substances

0.5 g of sample is placed in a 60 ml glass with screw cap for one hour at 70°C, and the headspace is analysed for volatile substances. The analyses are carried out as single determinations. Blind samples were included in the form of headspace analyses of empty glasses. The equipment was flushed with nitrogen to prevent cross-sample contamination.

An HP 5890 gas chromatograph with an HP 5972 mass spectrometer was used.

6.1.1.2 Semi-quantitative analysis for content of organic component in the products

A sample quantity weighed out (0.5-1 g) was transferred to an annealed 100-ml red cap glass.

Extraction was carried out with DCM (10 ml – sample labelled 33617-1, however 20 ml) to which was added deuterium-labelled internal standards (benzene-d6, toluene-d8, p-xylene-d10, naphthalene-d8 and DEHP-d4) using ultrasound and mechanical shaking.

Double determinations were carried out.

Analysis of extracts using GC-MS in scan mode.

Standards for BTEX, n-alkanes (C10-C36) and phthalates as well as other selected analytes were co-analysed.

The listed components were identified by comparing the current mass spectres with mass spectres in NIST library (Nist02 Version 2.0).

The quantities specified are calculated against the internal standard of naphthalene-d8 (5.69 µg/ml extraction liquid).

6.1.1.3 Screening for content of elements in artificial turf mats

The screening was carried out on artificial tuft mats nos. 1, 2, 4, 6, 7 and 8. The analysis was carried out on an Eagle III EDXRF instrument. The method is non-destructive to the material, as the sample is placed in the instrument’s test chamber which is evacuated, and the sample is then irradiated using X-rays. 300 µm spot was used at a voltage of 40 kV. Single determinations were carried out.

6.1.1.4 Quantitative screening analyses for zinc

Zinc analyses were made on selected samples of elastic infill and artificial turf mats in order to determine the concentration in the materials before the leaching tests.

The analysis conditions were as follows:

0.5 g of sample – carefully weighed – were prepared with 10 ml of concentrated nitric acid (subboiling quality) in an PFA autoclave through microwave-induced heating. The destruate was diluted with demineralised water (MilliQ plus) to 50 ml and filtered.

Blind samples were produced in a similar manner.

Double determinations were carried out.

The destruates were analysed for zinc content through inductively coupled plasma-atomic emission spectrometry (ICP-AES).

Quantification was made against standards made in nitric acid.

The calibration was verified against traceable control samples.

6.1.2 Leaching tests

Laboratory-scale leaching tests were carried out on the products selected for quantitative analysis, either to test for emissions of zinc or organic substances, based on the results from the preliminary screening analyses and quantitative zinc analyses.

Three aqueous contact media were subjected to leaching:

- Pure water (MilliQ quality)

Pure water to which was added 70 g technical sodium chloride road salt in a concentration of 70 g per litre - Pure water to which was added 70 g technical calcium chloride road salt in a concentration of 70 g per litre

The sodium chloride used was labelled Pioner Stensalt, Brøste, food quality, no additives, production date 22/02/07.

The calcium chloride was labelled calcium chloride, Flakes 77% CC tech, KOCC210198, Tetra 52 854 401, made in Finland by Tetra Chemicals.

Contact with pure water was selected for the scenario where the leaching from the artificial turf pitches is caused by rain.

Contact with sodium chloride and calcium chloride was selected for the two scenarios where winter salting is carried out. Sodium chloride, which is the cheapest type of thawing salt, is usually used, but during very cold periods either calcium chloride or magnesium are used instead.

The concentration of salt in the contact water was selected on the basis of DBU’s recommended salt solution concentration of 142 g/litre for the removal of ice and snow on the pitches. It was decided to halve this concentration as melting dilutes the solution. This has been estimated to be a factor of 2.

The pH of the sodium chloride solution was measured to be 4.7 using a pH meter, and the calcium chloride had a pH of 11.5, i.e. strongly alkaline. Following leaching, the calcium chloride liquids were still strongly alkaline (approx. pH = 11 measured using sticks). The strongly alkaline pH of the calcium chloride solution is deemed to be caused by calcium hydroxide residues.

The test conditions were as follows. 80.0 g of product was weighed out and to this was added 800.0 g of the contact medium. The artificial turf samples were divided up before contact with the water. The same applied to the tested pad.

For the zinc emission tests, 1 l polyethylene (PE) containers with PE screw-on caps were used. Prior to the test, the containers were flushed with diluted nitric acid of analysis quality and post-flushed with the contact medium. PE containers with the pure contact media were used as blank samples.

Annealed 1 l glass bottles with PE screw-on caps were used for the organic substance emission tests. As blind samples, glass bottles to which were added the contact media were also used.

The leaching occurred over a 24-hour period on a Gerhard Laboshake shaker. The containers and bottles were placed in horizontal position in the shaker.

Good liquid contact with all material was observed during the shaking process at the shaking rate applied of 120 directional changes per minute.

Upon completion of the tests, the contact water was filtered through a Büchner funnel using a Whatmann filter paper no. 42.

During filtration of the calcium chloride-based contact liquids, in a number of instances a significantly lower pressure drop was observed during filtration as well as foaming, indicating the conversion of organic substance and possibly saponification reactions as a result of the high pH of the contact liquid.

The filtrates were stored in a fridge until analysis.

The filtrates to be analysed for zinc content were made 0.14 M nitrate and analysed for the element using inductively coupled plasma atomic emission spectrometry (ICP-AES).

As mentioned above, the quantification was carried out against standards made in nitric acid and verified against traceable control samples.

The filtrates to be analysed for emissions of organic substances to the contact water were extracted using the following procedure:

500 ml of filtrate (possibly a small quantity) is made alkaline (pH = 10 using sodium hydroxide). Internal standards (bromobenzene and o-tert phenyl) were added together with 20 ml of DCM. The mixture was shaken for 30 min. The DCM phase was separated off and transferred to a glass bottle with anhydrous sodium sulphate as drying agent. The extraction was repeated with 10 ml of DCM which was transferred to the bottle.

The water phase was then made acidic (pH = 2) using hydrochloric acid.

The extraction procedure was the same as for the alkaline extraction to 20 ml of DCM. After having separated off the DCM phase, it was transferred to the bottle with the alkaline extract. The extraction was repeated with 5 ml of DCM, which was combined with the previous three extracts in the bottle.

Following the addition of internal standards, the extracts were analysed using GC/MS.

6.2 Results of screening analyses

6.2.1 Results of quantitative analysis for zinc in products

Table 6.1 Quantitative zinc content in selected products

| Product | Zn (mg/kg) |

| Infill no. 1 | 16,200 |

| Infill no. 2 | 18,500 |

| Infill no. 3 | 16,800 |

| Infill no. 4 | 16 |

| Infill no. 7 | 10,000 |

| Infill no. 13 | 15 |

| Infill no. 14 | 8,500 |

| Infill no. 15 | 8,300 |

| Infill no. 16 | 21,000 (stddev = 8,500) |

| Artificial turf no. 2 | 6.5 |

| Artificial turf no. 4 | < 3 |

| Artificial turf no. 6 | 1,100 (stddev = 1,240) |

| Artificial turf no. 8 | 150 |

| Pad no. 2 | 10,100 |

6.2.2 Results of X-ray screening for elements in selected turf mats

The analysis showed calcium as the only element in the turf base of the all turf mats tested.

Iron was observed in all grass leaves. In four out of seven turf mats tested, zinc in varying quantities was detected. In two of the samples, titanium was also detected. The surface of the sample (turf no. 6) with the highest zinc content was washed using 96% ethyl alcohol without causing changes in the zinc concentration. One of the samples also showed calcium. It is known that a supplier of UV stabilisers for plastics has a product containing calcium and zinc. This may explain why no leaching of zinc occurs with alcohol as would be expected if there was zinc stearate on the surface of the turf. Salts of stearic acid (Ca, Zn) act as release agents for plastic materials.

6.2.3 Headspace analysis

Headspace analyses were performed on infill nos. 1-5, nos. 7-9 as well as no. 11 and on artificial turf nos. 1, 2, 4 and nos. 6-8, as well as on both pads. The background for this prioritisation is to screen a representative selection of infill materials, artificial turf mats and pads within the limited framework of the project.

Table 6.2 Results of headspace analysis of selected infills and artificial turf products (µg/g)

| Component | CAS-no. | Pad no. 2 | Infill no. 1 | Infill no. 2 | Infill no. 3 | Infill no. 4 | Infill no. 7 | Infill no. 8 | Infill no. 9 | Artificial turf no. 2 |

| 2-Pyrrolidinone. 1-methyl- | 872-50-4 | 3.5 | ||||||||

| Benzene. 1.3-bis(1-methylethenyl)- | 3748-13-8 | 0.8 | ||||||||

| Benzene. 1.4-bis(1-methylethenyl)- | 1605-18-1 | traces | ||||||||

| Benzenemethanol. à.à-dimethyl- cumylalcohol | 617-94-7 | 0.7 | ||||||||

| Benzothiazole | 95-16-9 | 0.1 | ||||||||

| Butoxyethoxyethanol | 112-34-5 | 0.5 | 0.5 | |||||||

| Butylated hydroxytoluene (BHT) | 128-37-0 | 1.4 | ||||||||

| Cyclohexanamine | 108-91-8 | 2.7 | ||||||||

| Cyclohexanone | 108-94-1 | 0.9 | 0.7 | |||||||

| Ethanone. 1-[4-(1-hydroxy-1-methylethyl)phenyl]- * | 54549-72-3 | 1.3 | ||||||||

| Ethanone. 1-[4-(1-methylethenyl)phenyl]- (isopropenylacetophenone) | 5359-04-6 | 1.8 | ||||||||

| Heptanonitrile | 629-08-3 | 4.7 | ||||||||

| MIBK/2 hexanone | 108-10-1/ 591-78-6 |

0.5 | 5 | 12 | 3.4 | |||||

| N-cyclohexyl-formamide | 766-93-8 | |||||||||

| Nonanale | 124-19-6 | 0.3 | ||||||||

| Tertbutylacetophenone | 943-27-1 | 1.1 |

Results are only shown for products where substances above the detection limit were identified.

Table 6.3 shows substances identified in headspace analysis with potentially health or environmentally harmful effects based on the reference list of hazardous substances, the guiding list for self-classification or other data.

Table 6.3 Substances found with potential health and environmental effects

| Component | CAS-no. | Classification |

| 2-Pyrrolidinone, 1-methyl- | 872-50-4 | XI;R36/38 |

| Benzene, 1,3-bis(1-methylethenyl)- | 3748-13-8 | * R43 N;R50/53 |

| Benzene, 1,4-bis(1-methylethenyl)- | 1605-18-1 | * N;R50/53 |

| Benzothiazole | 95-16-9 | * Xn;R22 R43 |

| Butoxyethoxyethanol | 112-34-5 | XI;R36 |

| Butylated hydroxytoluene (BHT) | 128-37-0 | * Xn;R22 N;R50/53 |

| Cyclohexanamine | 108-91-8 | R10 XN;R21/22 C;R34 |

| Cyclohexanone | 108-94-1 | R10 XN;R20 |

| MIBK/2 hexanone | 108-10-1/591-78-6 | F;R11 XN;R20 XI;R36/37 R66 |

| Nonanale | 124-19-6 | * N;R50 |

| Tertbutylacetophenone | 943-27-1 | * R52/53 |

* Danish Environmental Protection Agency, 2001

6.2.4 Results of analysis for content of organic substances by extraction in dichloromethane

Table 6.4 Results of extraction in DCM of pads and infills (µg/g)

Table 6.5 Results of extraction in DCM of artificial turf (µg/g)

| Component | CAS-no. | Artificial turf no. 1 |

Artificial turf no. 2 |

Artificial turf no. 4 |

Artificial turf no. 6 |

Artificial turf no. 7 |

Artificial turf no. 8 |

| 4,4'-((p-Phenylene) diisopropylidene)di-phenol |

2167-51-3 | 51 | |||||

| Erucylamide | 112-84-5 | 88 | 146 | 177 | |||

| Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate | 52829-07-9 | 173 | |||||

| Butoxyethoxy- ethylacetate |

124-17-4 | 22 | |||||

| Cyclohexanamine | 108-91-8 | ||||||

| DEHP | 117-81-7 | 80 | 104 | 43 | |||

| Nonylphenol | 25154-52-3 | 16 | |||||

| Octylphenols/ nonylphenols |

56 | 57 |

Table 6.6 shows substances found by extraction in DCM having potentially health or environmentally harmful effects based on the reference list of hazardous substances, the guiding list for self-classification or other data.

Table 6.6 Substances found with potential health and environmental effects

| Component | CAS no. | Classification |

| 1,4-Benzendiamine, N-(1,3-dimethylbutyl)-N'-phenyl- (6PPD) | 793-24-8 | * R43 N;R50/53 |

| 1-Dodecanamine, N,N-dimethyl- | 112-18-5 | * R43 N;R50/53 |

| 1-Tetradecanamine, N,N-dimethyl- | 112-75-4 | * Xn;R22 R43 N;R51/53 |

| 2-(5-Chloro-2-benzotriazolyl)-6-tert-butyl-p-cresol | 3896-11-5 | * Xn;R22 |

| 2-Pyrrolidinone, 1-methyl- | 872-50-4 | XI;R36/38 |

| Erucylamide | 112-84-5 | |

| Aniline | 62-53-3 | T;R23/24/25-48/23/24/25 CARC3;R40 XI;R41 R43 MUT3;R68 N;R50 |

| Benzophenone, 2-hydroxy-4-(octyloxy)- (Octabenzone) | 1843-05-6 | A fraction in hsdb benzophenone: 119-61-9 (hormone effects) |

| Benzothiazole | 95-16-9 | * Xn;R22 R43 |

| Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate | 52829-07-9 | * N;R51/53 |

| Butoxyethoxyethylacetate | 124-17-4 | * R52/53 |

| Butylated hydroxytoluene (BHT) | 128-37-0 | * Xn;R22 N;R50/53 |

| Cyclohexanamine | 108-91-8 | R10 XN;R21/22 C;R34 |

| DEHP | 117-81-7 | REP2;R60-61 |

| Dibutylphthalate | 84-74-2 | * N;R51/53 |

| Diisobutylphthalate | 84-69-5 | * N;R50/53 |

| D-limonene | 5989-27-5 | R10 XI;R38 R43 N;R50/53 |

| Nonylphenol | 25154-52-3 | XN;R22 C;R34 REP3; R62-63 N;R50/53 |

| N-phenyl-1-naphtaleneamine | 90-30-2 | * Xn;R22 R43 |

| Octylphenols/nonylphenols | See nonylphenol octylphenol:27193-28-8: *Xn;R22 R43 N;R50/53 | |

| Phenol, 2,4-bis(1,1-dimethylethyl)- | 96-76-4 | * N;R51/53 |

| Phenol, 2-(5-chloro-2H-benzotriazol-2-yl)-4,6-bis(1,1-dimethylethyl)- or similar | 3864-99-1 | * N;R50/53 |

| Hexylbenzene | 1077-16-3 | * N;R50/53 |

* Danish Environmental Protection Agency, 2001

Based on the results of extraction in DCM, a number of representative products were selected for subsequent tests of leaching into aqueous contact liquids. The products for the leaching tests were selected so that substances having health and environmentally harmful properties and high concentration were weighted most. In addition, it has also been taken into account whether the substances occur in many or few products.

6.3 Results of leaching tests

Table 6.7 Leaching of zinc

| Sample marked | Zn mg/l |

| Infill no. 1 MilliQ 1 | 0.59 |

| Infill no. 1 NaCl | 7.4 ² |

| Infill no. 1 CaCl2 | 0.36 |

| Infill no. 3 MilliQ | 1.4 |

| Infill no. 3 NaCl | 0.38 |

| Infill no. 3 CaCl2 | < 0.05 |

| Infill no. 7 MilliQ | < 0.05 |

| Infill no. 14 MilliQ | 0.06 |

| Infill no. 14 NaCl | 0.11 |

| Infill no. 14 CaCl2 | 0.94 |

| Infill no. 15 MilliQ | 2.3 |

| Infill no. 15 NaCl | 11 ² |

| Infill no. 15 CaCl2 | 1.5 |

| Infill no. 16 MilliQ | 0.80 |

| Blank NaCl | < 0.05 |

| Blank CaCl2 | < 0.05 |

| Pad 2 MilliQ | 0.27 |

| Pad 2 NaCl | 0.41 |

1 MilliQ is extremely pure ion-exchanged, membrane-filtered water

2 The values are considered to be contaminated analyses as results in MilliQ and CaCl2 in the same series give much lower results. These high analysis values are not included in the subsequent environmental assessment.

Table 6.8 Leaching of organic substances from elastic infills (µg/l)

| Component | CAS-no. | Infill no. 1 | Infill no. 1 | Infill no. 2 | Infill no. 3 | Infill no. 3 | Infill no. 4 |

| MilliQ | CaCl2 | MilliQ | MilliQ | CaCl2 | MilliQ | ||

| 5-Methyl-2-hexanone | 110-12-3 | 7 | 6 | 6 | |||

| Cyclohexanone | 108-94-1 | 80 | 95 | 107 | 112 | 123 | |

| Ethanol, 2-butoxy- | 111-76-2 | 13 | 19 | ||||

| Benzaldehyde | 100-52-7 | ||||||

| Benzene, isocyanato- | 103-71-9 | 17 | 9 | 8 | |||

| Cyclohexane, isocyanato- | 3173-53-3 | 27 | 46 | 31 | 37 | 31 | |

| 2-Pyrrolidinone, 1-methyl- | 872-50-4 | 613 | 847 | ||||

| Benzaldehyde, 2-hydroxy- | 90-02-8 | 6 | |||||

| Acetophenone | 98-86-2 | 6 | 5 | 6 | 6 | 108 | |

| Hexanoic acid, 2-ethyl- | 149-57-5 | 38 | 64 | 31 | 35 | 23 | |

| Ethanol, 1-(2-butoxyethoxy)- | 54446-78-5 | 7 | 171 | 334 | |||

| Cyclohexane, isothiocyanato- | 1122-82-3 | 10 | 17 | 16 | |||

| N-cyclohexyl-formamide | 766-93-8 | 161 | 214 | 139 | 172 | 233 | |

| Acetamide, N-cyclohexyl- | 1124-53-4 | 9 | 21 | 56 | |||

| Phenol, m-tert-butyl- | 585-34-2 | 365 | 207 | ||||

| Cyclohexanamine, N-cyclohexyl- | 101-83-7 | 1167 | 12 | 573 | 255 | ||

| Phenol, 2,4-bis(1,1-dimethylethyl)- | 96-76-4 | ||||||

| Cyclohexanamine, N-cyclohexyl-N-methyl- | 7560-83-0 | 126 | 138 | 76 | |||

| Cycloheptasiloxane, tetradecamethyl- | 107-50-6 | ||||||

| Diethylphthalate | 84-66-2 | 61 | 32 | 73 | |||

| Benzothiazole, 2-(methylthio)- | 615-22-5 | 6 | 29 | 11 | 13 | 24 | |

| Dodecanoic acid | 143-07-7 | 14 | 28 | 19 | |||

| Benzothiazolone | 934-34-9 | 239 | 754 | 277 | 231 | 802 | |

| 3,5-Di-tert-Butyl-4-hydroxybenzaldehyde | 1620-98-0 | 132 | 86 | ||||

| Diisobutylphthalate | 84-69-5 | 83 | 21 | 98 | 94 | 93 | |

| Dibutylphthalate | 84-74-2 | 72 | 170 | 69 | 178 | ||

| 1,3-Dicyclohexylurea | 2387-23-7 | 30 | 19 | 38 | 28 | 18 | |

| 1,4-Benzendiamin, N-(1-methylethyl)-N’-phenyl-, (IPPD) | 101-72-4 | 73 | |||||

| Benzylbutylphthalate | 85-68-7 | ||||||

| DEHP | 117-81-7 | 14 | |||||

| Hexa(methoxymethyl)melamine | 68002-20-0 | 1380 | 1320 | 1200 | 1860 | 1760 | |

| Aniline | 62-53-3 | 16 | |||||

| Benzothiazole | 95-16-9 | 528 | 385 | 293 | 578 | 437 | |

| Cyclohexanamine | 108-91-8 | ||||||

| Ethanone, 1,1'-(1,3-phenylene)bis- | 6781-42-6 | 23747 | |||||

| Ethanone, 1,1'-(1,4-phenylene)bis- | 1009-61-6 | 6965 | |||||

| Ethanone, 1-[4-(1-methylethenyl)phenyl]- | 5359-04-6 | 13378 | |||||

| Ethanone, 1-[4-(1-methylethenyl)phenyl]- | 5359-04-6 | 4949 | |||||

| Drometrizol | 2440-22-4 | ||||||

| 2-(1-phenylethyl)-phenol | 4237-44-9 | 11 | |||||

| Degradations products of 1,4-Benzenediamine, N-(1,3-dimethylbutyl)-N'-phenyl- (6PPD) | 793-24-8 | 687 | 391 | 641 | 324 | 266 |

Table 6.8 Leaching of organic substances from elastic infills (µg/l), contd.

| Component | CAS-no. | Infill no. 10 | Infill no. 11 | Infill no. 11 | Infill no. 14 | Infill no. 14 |

| MilliQ | MilliQ | CaCl2 | MilliQ | CaCl2 | ||

| 5-ethyl-2-hexanone | 110-12-3 | |||||

| Cyclohexanone | 108-94-1 | 219 | 99 | |||

| Ethanol, 2-butoxy- | 111-76-2 | |||||

| Benzaldehyde | 100-52-7 | 2 | 2 | |||

| Benzene, isocyanato- | 103-71-9 | 8 | ||||

| Cyclohexane, isocyanato- | 3173-53-3 | 22 | 26 | |||

| 2-Pyrrolidinone, 1-methyl- | 872-50-4 | |||||

| Benzaldehyde, 2-hydroxy- | 90-02-8 | |||||

| Acetophenone | 98-86-2 | 3 | 22 | 11 | ||

| Hexanoic acid, 2-ethyl- | 149-57-5 | |||||

| Ethanol, 1-(2-butoxyethoxy)- | 54446-78-5 | 26 | 42 | |||

| Cyclohexane, isothiocyanato- | 1122-82-3 | |||||

| N-cyclohexyl-formamide | 766-93-8 | 561 | 321 | |||

| Acetamide, N-cyclohexyl- | 1124-53-4 | 62 | 35 | |||

| Phenol, m-tert-butyl- | 585-34-2 | 14 | 16 | |||

| Cyclohexanamine, N-cyclohexyl- | 101-83-7 | 99 | 12 | |||

| Phenol, 2,4-bis(1,1-dimethylethyl)- | 96-76-4 | 250 | 78 | 54 | 56 | 20 |

| Cyclohexanamine, N-cyclohexyl-N-methyl- | 7560-83-0 | |||||

| Cycloheptasiloxane, tetradecamethyl- | 107-50-6 | 56 | ||||

| Diethylphthalate | 84-66-2 | 71 | 100 | 146 | ||

| Benzothiazole, 2-(methylthio)- | 615-22-5 | 23 | ||||

| Dodecanoic acid | 143-07-7 | 306 | 28 | 56 | 58 | |

| Benzothiazolone | 934-34-9 | 118 | 449 | |||

| 3,5-di-tert-Butyl-4-hydroxybenzaldehyde | 1620-98-0 | 6 | 10 | |||

| Diisobutylphthalate | 84-69-5 | 30 | 76 | 81 | 24 | |

| Dibutylphthalate | 84-74-2 | 61 | 65 | 158 | 7 | |

| 1,3-Dicyclohexylurea | 2387-23-7 | 73 | 68 | |||

| 1,4-Benzendiamine, N-(1-methylethyl)-N’-phenyl-, (IPPD) | 101-72-4 | |||||

| Benzylbutylphthalate | 85-68-7 | 43 | ||||

| DEHP | 117-81-7 | 114 | 83 | |||

| Hexa(methoxymethyl)melamine | 68002-20-0 | |||||

| Aniline | 62-53-3 | 6 | ||||

| Benzothiazole | 95-16-9 | 18 | 245 | 574 | ||

| Cyclohexanamine | 108-91-8 | 1610 | 533 | |||

| Ethanone, 1,1'-(1,3-phenylen)bis- | 6781-42-6 | |||||

| Ethanone, 1,1'-(1,4-phenylen)bis- | 1009-61-6 | |||||

| Ethanone, 1-[4-(1-methylethenyl)phenyl]- | 5359-04-6 | |||||

| Ethanone, 1-[4-(1-methylethenyl)phenyl]- | 5359-04-6 | |||||

| Octylphenols/Nonylphenols | 0 | |||||

| Drometrizol | 2440-22-4 | 955 | 5794 | 494 | ||

| 2-(1-Phenylethyl)-phenol | 4237-44-9 | |||||

| 2-Ethyl-1-hexanol | 104-76-7 | 3 |

Table 6.9 Leaching of organic substances from artificial turf (µg/l)

| CAS-nr. | Artificial turf no. 2 |

Artificial turf no. 4 |

Artificial turf no. 4 |

Artificial turf no. 7 |

Blank | Blank | |

| MilliQ | MilliQ | CaCl2 | MilliQ | MilliQ | CaCl2 | ||

| Diethylphthalate (DEP) | 84-66-2 | 359 | 302 | < LOD | 335 | < LOD | < 0,2 |

| Diisobutylphthalate(DIBP) | 84-69-5 | 118 | 112 | 10 | 144 | 5 | 8 |

| Dibutylphthalate (DBP) | 84-74-2 | 137 | 155 | 5 | 183 | 3 | 2 |

| Benzylbutylphthalate (BBP) | 85-68-7 | < LOD | 42 | < LOD | 47 | < LOD | < LOD |

| Bis(2-ethylhexyl)phthalate(DEHP) | 117-81-7 | 14 | 183 | 5 | 87 | 2 | 2 |

| Dicyclohexylphthalate (DCHP) | 84-61-7 | < LOD | 82 | 6 | 88 | < LOD | < LOD |

| Nonylphenol | 84852-15-3 | 143 | 384 | 175 | 150 | < LOD | < LOD |

| Bis-(2,2,6,6-tetramethyl-4-piperidinyl)sebacate | 52829-07-9 | 137 | 5 | 183 | 353000 1 | < LOD | < LOD |

| Erucylamide | 112-84-5 | 644 | 1771 | 4 | < LOD | < LOD | < LOD |

1 The concentration of the substance was extremely high in this sample, and the figure is based on a series of dilutions. The analysis result correlates with a very high content of the substance found in the DCM extraction.

6.3.1 Microscopy

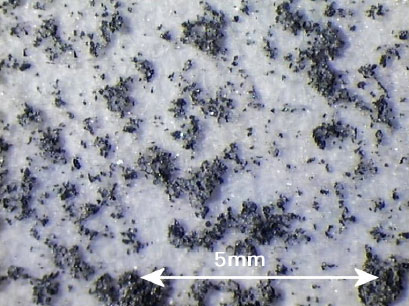

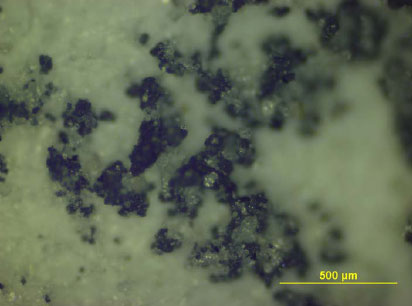

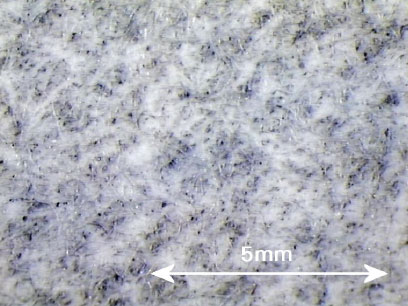

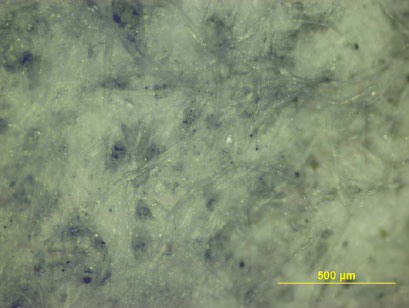

As the particle size of rubber dust is significant regarding any impact on a potential inhalation health risk, microscopy was performed of filtered-off fine dust particles from two of the leaching tests for zinc analysis with infill 14 and infill 15. In these leaching tests, high filter resistance was observed, indicating the presence of fine particulate material.

The sample from infill 14 contained black and white/transparent particles (10-50 µm) – the majority being transparent.

The sample from infill 15 almost only contained black particles, and there were no white particles on the one rubber fragment in the dish.

Figure 6.1 Picture of filtered-off dust particles on filter paper from leaching test with infill 14, large-scale

Figure 6.2 Picture of filtered-off particles on filter paper from leaching test with infill 14, enlarged

Figure 6.3 Picture of filtered-off particles on filter paper from leaching test with infill 15, large-scale

Figure 6.4 Picture of filtered-off particles on filter paper from leaching test with infill 15, enlarged

It is assessed that the fine dust is the probable cause of the increased filter resistance in the pores during filtration.

There is no simple pattern for filter clogging from the contact tests. The filtration problems were thus observed both for SBR rubber infill and for EPDM rubber infill. The filtration problems were observed on both new and used infills. This indicates that the fine particulate substance with a clogging effect is also present in the unused infill material from the start and not as a result of wear. The most probable explanation for the fine dust is that it is fine particulate rubber in the actual infill material, which is also supported by the microscopy pictures.

As mentioned above, the contact tests using a calcium chloride solution were generally found to provide the best filtration.

6.4 Discussion of results

Significantly higher amounts of leached phthalates were found from elastic infills of SBR-based infills in this study than in the results from the Norwegian study (T. S.W. Plesser, 2004). The reason for this may, e.g., be a higher content of the substances, that the substances are found in higher amounts on the surface of particles, that the substances are bound to finer particles with a shorter diffusion path, or that a more efficient leaching process was used with better liquid-solid contact in the present studies.

Table 6.10 shows, for some substances, how much the leached amount corresponds to in relation to the content in elastic infills and artificial turf

Table 6.10 Amount of leached substance in relation to content as determined by DCM extraction

| Substance | Elastic infill % leached, 24 hours |

Artificial turf % leached, 24 hours |

| Dibutylphthalate (DBP) | 3.6 | |

| Diisobutylphthalate (DIBP) | 0.6 | |

| Diethylhexylphthalate (DEHP) | 1.9 | 1.8 |

| Nonylphenol | 6.7 |

As can be seen, a limited amount of phthalate and nonylphenol leached out after a 24-hour extraction period compared to the total sample content.

Bis-(2,2,6,6-tetramethyl-4-piperidinyl)sebacate was found in very high concentrations in leaching tests of artificial turf no. 7. The amount indicates that the substance is present in a weight quantity of 0.35 percent by weight, where the measurement result of the DCM extraction was 0.0173 percent by weight. In this context, it should be noted that the substance is very water-soluble with log Kow = 0.35, for which reason only a small quantity is expected to be extracted to DCM. The high concentration observed in the leaching test is thus not unrealistically high if it is assumed that most of the substance added has leached out. The substance is a so-called HALS (hindered amine stabiliser), which is a group of chemical substances that stabilise plastics against photochemically induced degradation. The water solubility of the substance makes it an inappropriate choice.

Table 6.12 shows results of leaching of infills from the present Danish study as well as the Norwegian study (T.S.W. Plesser, 2004).

Table 6.11 Leached substances in Norwegian and Danish infill studies

| Substance | Liquid from leaching test. Elastic infill Norway µg/l |

Liquid from leaching test. Elastic infill Denmark µg/l |

| Zn | 3300 | 600-2300 |

| DEHP | 5.5 | 14-114 |

| Diethylphthalate (DEP) | 6.6-8.3 | 32-146 |

| Dibutylphthalate (DBP) | 2.1-3.3 | 61-178 |

| Sum of phthalates (not DEHP) | 6-16 | 162-428 |

| Sum of octylphenol and nonylphenol | 4.5 | - |

Table 6.12 shows the content of phthalates and nonylphenol observed in infills and artificial turf in the Norwegian and Danish studies.

Table 6.12 Content of some substances in infills, Danish and Norwegian studies

| Substance | Elastic infill, Norway µg/g | Elastic infill, Denmark µg/g | Elastic artificial turf, Norway µg/g | Elastic artificial turf, Denmark µg/g |

| Diethylphthalate (DEP) | 1.5 | ? | ? | |

| Dibutylphthalate (DBP) | 1.6-3.9 | 50 | 1 | ? |

| Diisobutylphthalate (DIBP) | Not detected | 77-175 | ||

| Diethylhexylphthalate (DEHP) | 3.9-29 | 52-62 | 1.7-8 | 43-104 |

| Diisononylphthalate (DINP) | 57-78 | Not found | 5.5 | |

| Nonylphenol | 21 | 0.2 | 16-57 |

As shown in the table, there is a significantly higher concentration of DBP, DIBP and DEHP in infills in the Danish study compared to the Norwegian study. The Norwegian study has, on the other hand, found DINP in concentrations comparable to the phthalate (DBP, DIBP, DEHP) concentrations in the Danish study. This may go some way to explaining the higher leaching of phthalates observed from infills in the Danish study, as shown in Table 6.11. The content of both phthalates and nonylphenols in artificial turf is far higher in the Danish study than in the Norwegian, resulting in a high leaching level.

6.5 Selection of substances for health and environmental assessment

Foreign studies of the emissions of volatile chemical substances unanimously conclude that the health effects from inhalation are insignificant. Headspace analyses of evaporation from elastic infills, artificial turf mats and pads in the present study have confirmed that the emission of volatile substances is insignificant. It has thus been decided to exclusively focus on oral intake and dermal uptake in the health assessment.

Based on the concentrations of chemical substances found in leaching tests as well as the hazardous properties of the substances, it has been decided to assess the effects of:

- Benzothiazole

- Dicyclohexylamine

- Cyclohexanamine

- Dibutyl phthalate

In the leaching tests, a number of potentially environmentally harmful substances were also found, and it has been decided to assess a representative selection of these:

- Zinc and its salts

- 6PPD

- Dicyclohexylamine

- Diisobutyl phthalate

- Nonylphenol

- 2,4-Di-tert-butylphenol

The substances selected are representative for the substance groups which were expected to be relevant to assess before carrying out the analyses (see Section 4.2.2).

Version 1.0 October 2008, © Danish Environmental Protection Agency